Method for refining pyrolysis lignin in biological oil

A technology for pyrolyzing lignin and bio-oil, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., and can solve the problems of coking, poor stability, and low cracking efficiency of pyrolyzed lignin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

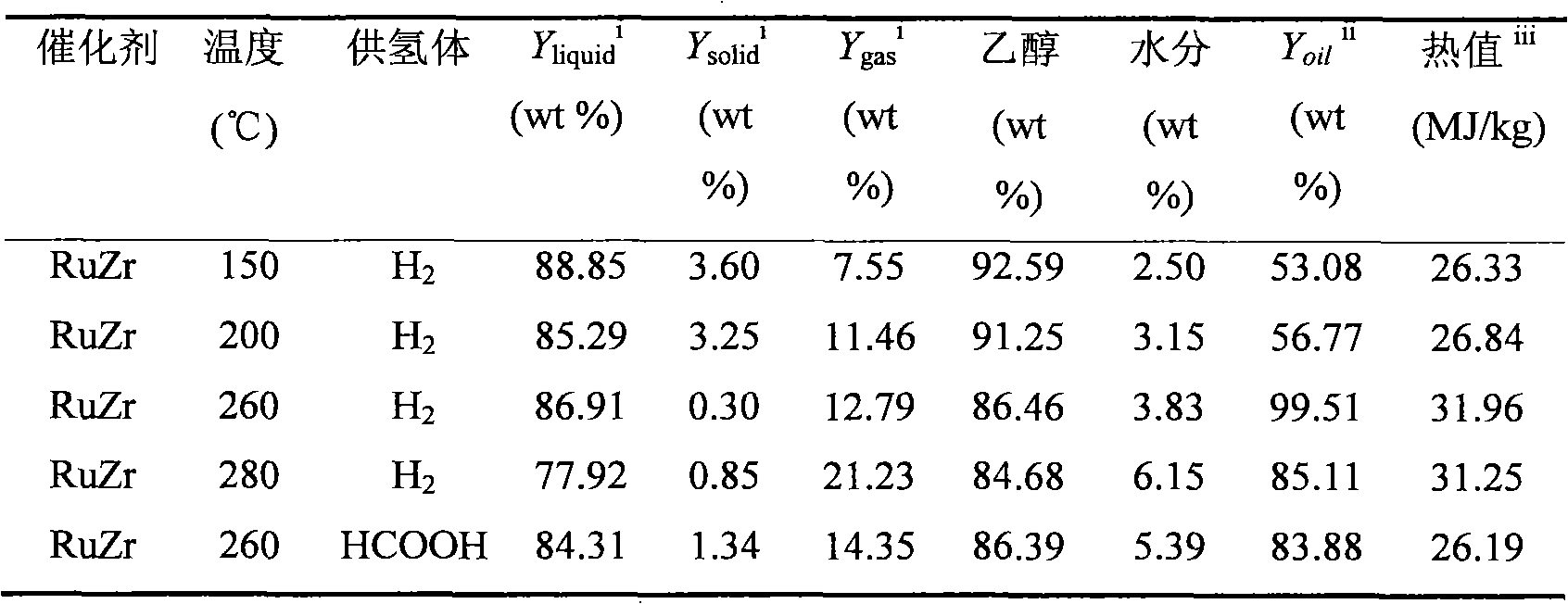

[0026] Weigh 1 part of pyrolytic lignin and 11 parts of ethanol and put it into a 150mL autoclave, then drop into 0.5 part of catalyst (3%Ru / ZrO 2 / SBA-15, denoted as RuZr). Replace the air in the kettle with hydrogen for three to four times, and then fill it with 2MPa hydrogen to minimize the air content in the kettle, especially the oxygen content, so as to maintain the reducing atmosphere in the kettle. Turn on the stirring device to about 1000 rpm, then heat to 150° C. and maintain it for 8 hours. After the reaction was finished, it was cooled to room temperature, and liquid, gas and solid products were collected. Liquid and gaseous products were analyzed for their chemical composition by GC-MS and GC. Its result is: liquid yield is 88.85%; Solid yield is 3.60%; Gas yield is 7.55%; Pyrolytic lignin cracking is the yield of liquid organic matter, i.e. the yield of pyrolysis oil (Y oil ) and calorific value are 53.08% and 26.33MJ / Kg respectively.

Embodiment 2

[0028] Weigh 1 part of pyrolytic lignin and 11 parts of ethanol and put it into a 150mL autoclave, then drop into 0.5 part of catalyst (3%Ru / ZrO 2 / SBA-15, denoted as RuZr). Replace the air in the kettle with hydrogen for three to four times, and then fill it with 2MPa hydrogen to minimize the air content in the kettle, especially the oxygen content, so as to maintain the reducing atmosphere in the kettle. Turn on the stirring device to about 1000 rpm, then heat to 200°C and maintain it for 8 hours. After the reaction was finished, it was cooled to room temperature, and liquid, gas and solid products were collected. Liquid and gaseous products were analyzed for their chemical composition by GC-MS and GC. Its result is: liquid yield is 85.29%; Solid yield is 3.25%; Gas yield is 11.46%; Pyrolytic lignin cracking is the yield of liquid organic matter, i.e. the yield of pyrolysis oil (Y oil ) and calorific value are 56.77% and 26.84MJ / Kg respectively.

Embodiment 3

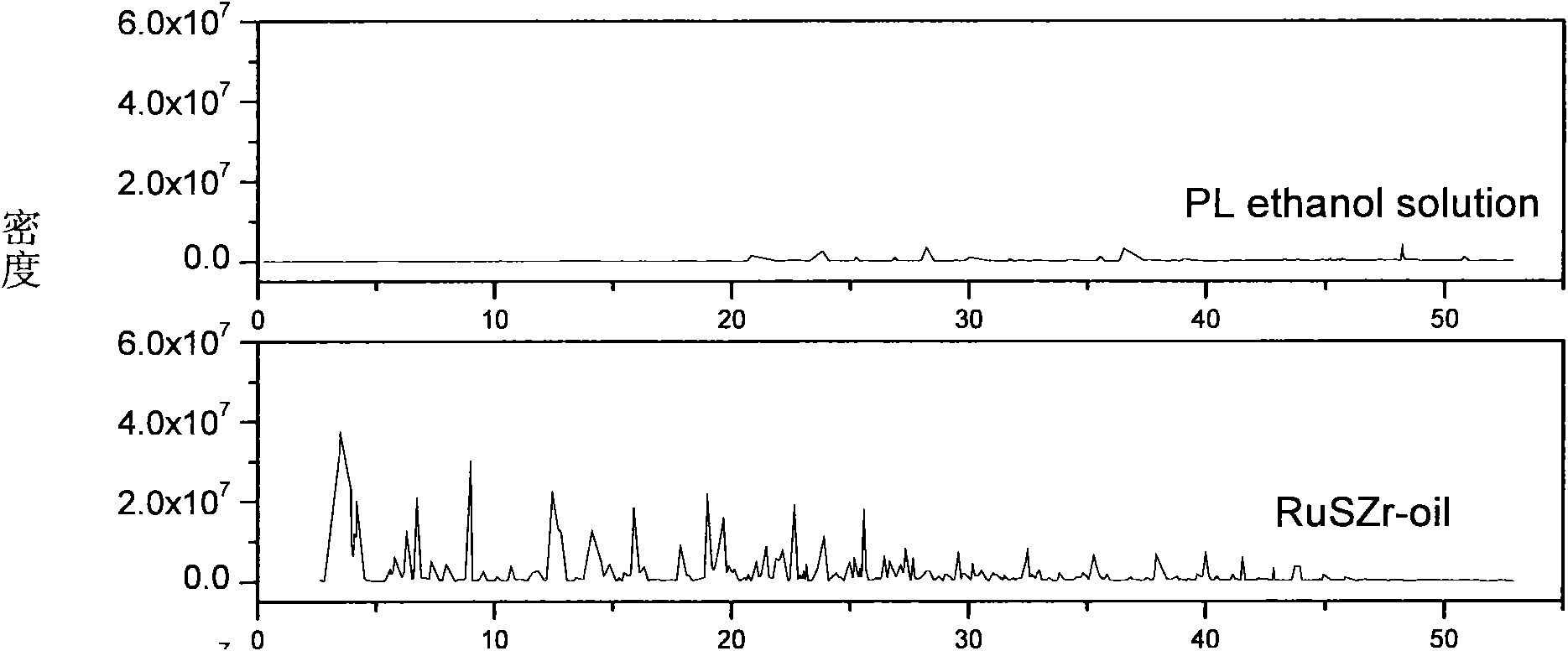

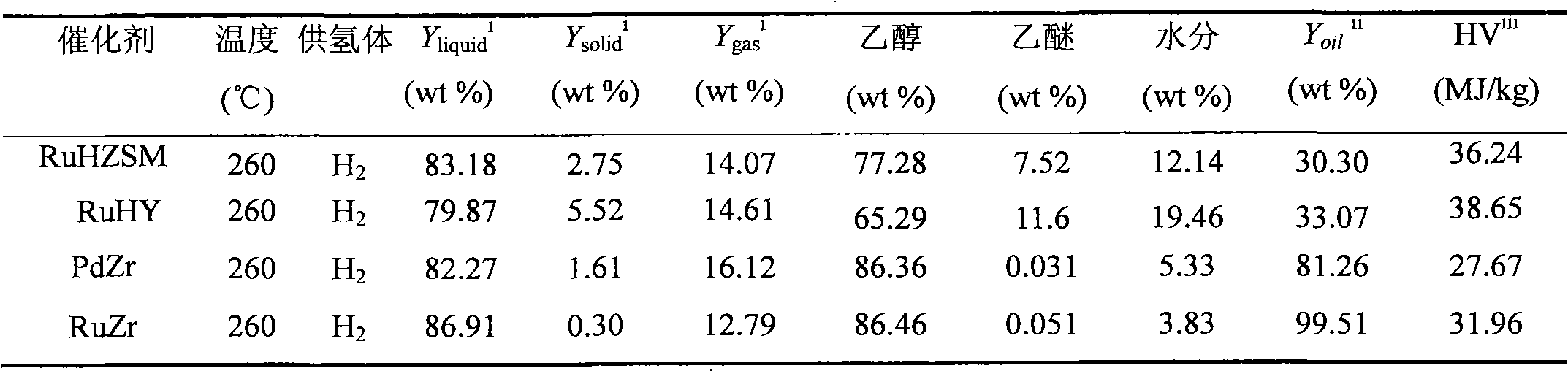

[0030] Weigh 1 part of pyrolytic lignin and 11 parts of ethanol and put it into a 150mL autoclave, then drop into 0.5 part of catalyst (3%Ru / ZrO 2 / SBA-15, denoted as RuZr). Replace the air in the kettle with hydrogen for three to four times, and then fill it with 2MPa hydrogen to minimize the air content in the kettle, especially the oxygen content, so as to maintain the reducing atmosphere in the kettle. Turn on the stirring device to about 1000 rpm, then heat to 260° C. and maintain it for 8 hours. After the reaction was finished, it was cooled to room temperature, and liquid, gas and solid products were collected. Liquid and gaseous products were analyzed for their chemical composition by GC-MS and GC. Its result is: liquid yield is 86.91%; Solid yield is 0.30%; Gas yield is 12.79%; Pyrolytic lignin cracking is the yield of liquid organic matter, i.e. the yield of pyrolysis oil (Y oil ) and calorific value are 99.51% and 31.96MJ / Kg respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com