Electropolishing method for austenitic stainless steel orifice

A technology of austenitic stainless steel and electrolytic polishing, which is applied in the direction of electrolytic process and electrolytic components, and can solve problems such as excessive voltage and current, difficulty in achieving heat and burns, and poor fluidity of the solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The polishing solution used in this embodiment is as follows: every liter of the mixed solution contains 1100 g of phosphoric acid with a concentration of 85%; 240 g of sulfuric acid with a concentration of 95%; and 210 g of absolute ethanol with a concentration of 99.5%. The voltage is 4V; the current density is 10A / dm 2 .

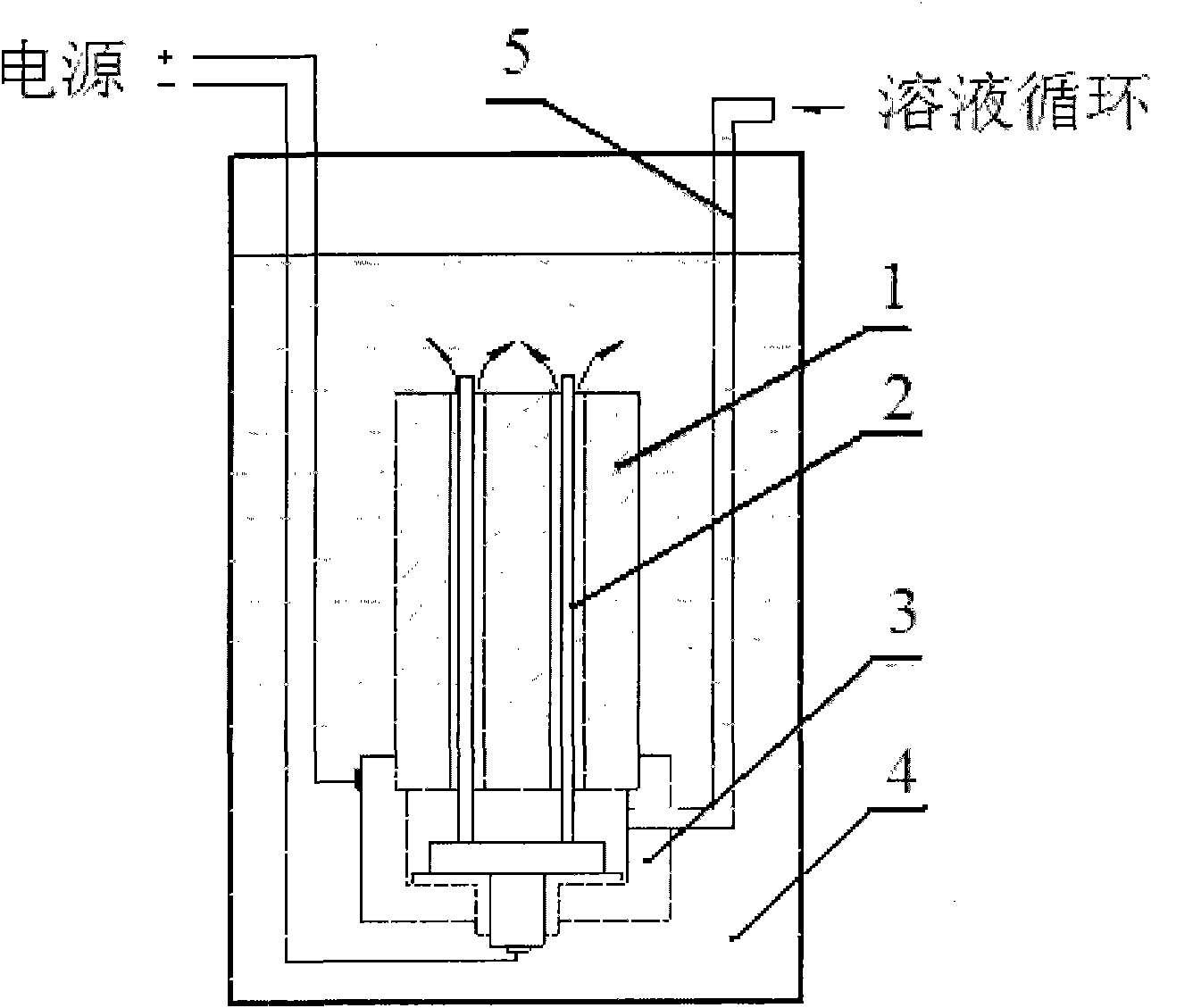

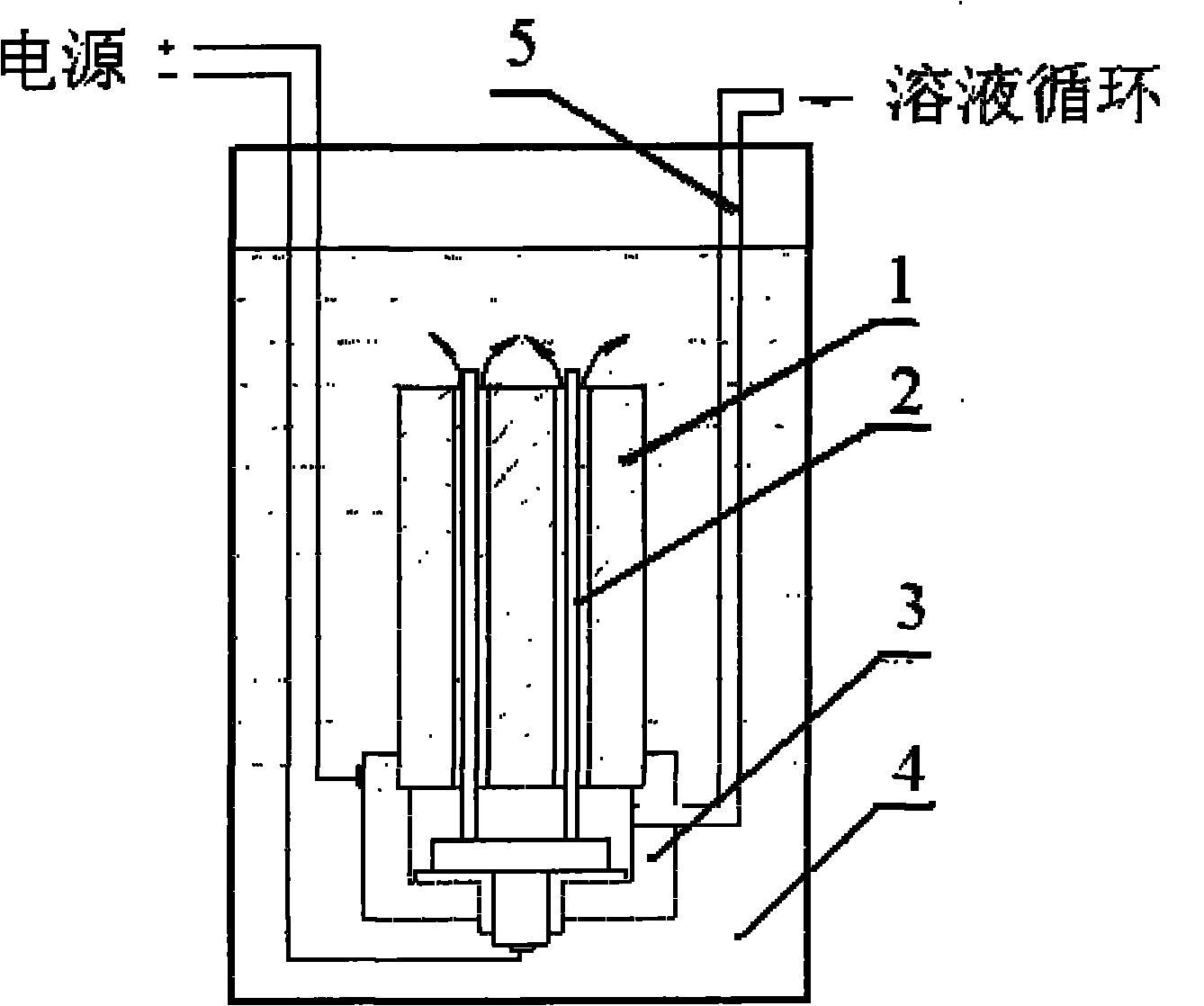

[0029] figure 1 It is a schematic diagram of the electrolytic polishing process for small through-holes of stainless steel according to an embodiment of the present invention. During electropolishing, the workpiece 1 is first passed through the electrode needle 2 and fixed on the clamping device 3, so that the workpiece 1, the clamping device 3 and the tube 5 jointly form a solution circulation channel, and then the whole is immersed in the polishing solution 4 ( Solution temperature: 50-65°C), tube 5 is connected to solution circulation equipment (peristaltic pump or electromagnetic metering pump, etc.) The anode (the positive pole of the power...

Embodiment 2

[0031] The polishing solution used in this embodiment is: every liter of mixed solution contains 1000g of phosphoric acid with a concentration of 85%; 200g of sulfuric acid with a concentration of 95%; 180g of dehydrated alcohol with a concentration of 99.5%, and 6.5ml glycolic acid solution with a concentration of 35% %. The voltage is 4.2V; the current density is 15A / dm 2 .

[0032] figure 1 It is a schematic diagram of the electrolytic polishing process for small through-holes of stainless steel according to another embodiment of the present invention. During electropolishing, the workpiece 1 is first passed through the electrode needle 2 and fixed on the clamping device 3, so that the workpiece 1, the clamping device 3 and the tube 5 jointly form a solution circulation channel, and then the whole is immersed in the polishing solution 4 ( Solution temperature: 50-65°C), tube 5 is connected to solution circulation equipment (peristaltic pump or electromagnetic metering pu...

Embodiment 3

[0034] The polishing solution used in this embodiment is: every liter of mixed solution contains 1250g of phosphoric acid with a concentration of 85%, 260g of sulfuric acid with a concentration of 95%; 240g of absolute ethanol with a concentration of 99.5%; the voltage is 2.5V; the current density is 3.5 A / dm 2 .

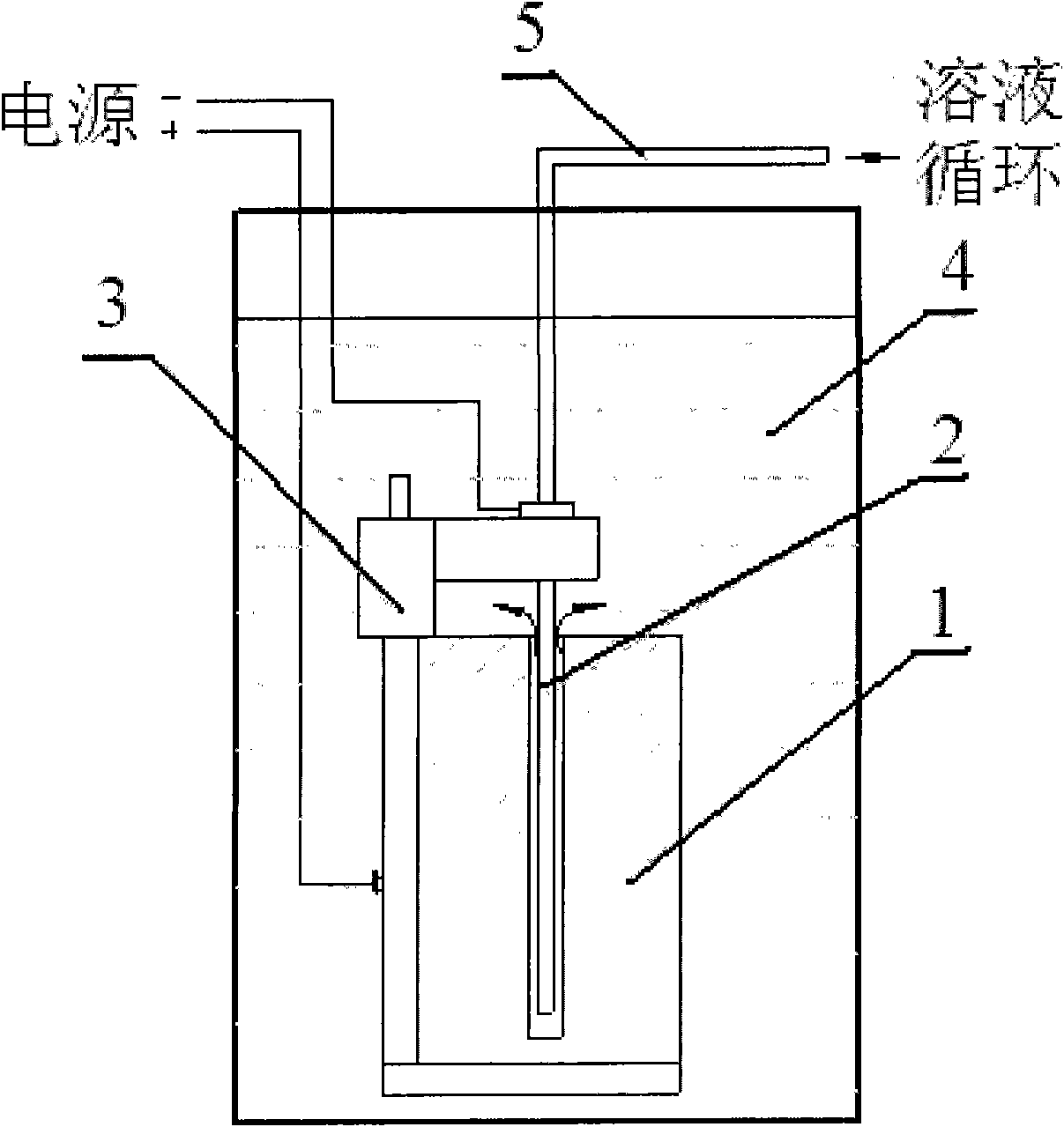

[0035] figure 2 It is a schematic diagram of the electrolytic polishing process of stainless steel deep blind holes according to another embodiment of the present invention. Its basic principle is the same as above, and the main difference is that the electrode needle 2 is a small tube electrode, which is fixed by a clamping device. The connection acts as a cathode for conducting electricity, and on the other hand, it is also connected with the tube 5 to form a solution circulation channel to transport the solution. The solution circulation is to transport the solution to the bottom of the small hole through the tube electrode, and then flow out from the bottom t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com