Combined type seawall and construction method thereof

A composite seawall technology, applied in jetties, embankments, breakwaters, etc., can solve the problems of weak impact resistance of seawalls, long settlement stability time, large seawall settlements, etc., achieving obvious environmental protection benefits and short construction period , The impact resistance of the seawall is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

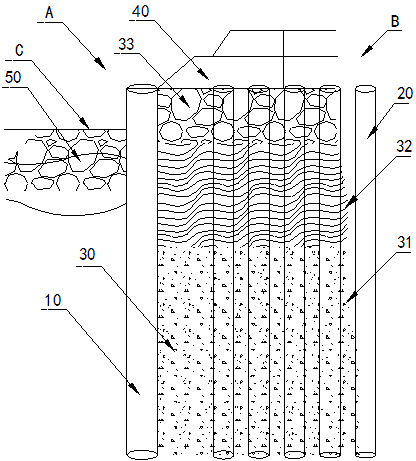

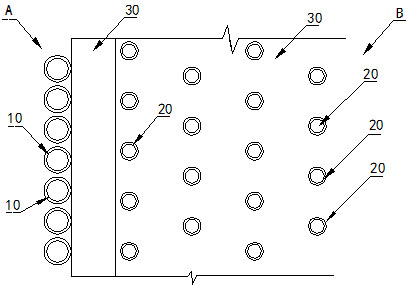

[0022] figure 1 , figure 2 , image 3 In the shown embodiment, a composite seawall includes seawall barrel piles, and a row of vertical rigid cast-in-situ 1500mm large-diameter ribbed piles exposed to the sea level C are driven into the original shoal mud 50 on the outer shallow sea side A. Seawall barrel piles 10, the reinforcement cage is installed in the annular body of the seawall barrel piles 10 with ribs, and the seawall barrel piles 10 with large diameters are conjoined and interlocked. The side B carries out blow filling and raises the blow packing 30 above sea level, and the blow packing 30 comprises the clay layer 31 at the bottom, the riprap layer 33 at the top and the silt layer 32 in the middle part; A row of 1000mm cast-in-place large-diameter plain-tube seawall piles 20, no reinforcement cage is installed in the annular body of the diameter-diameter plain-tube seawall piles 20, and multiple rows of cast-in-place large-diameter plain-tube seawall piles 20 are...

Embodiment 2

[0024] There is a gap between the large-diameter ribbed seawall piles 10, the gap is provided with a sealing board, and the method of adding a board is used to seal the gap, and the rest is the same as that of Embodiment 1.

Embodiment 3

[0026] There is a gap between the large-diameter ribbed seawall piles 10, the gap is provided with a sealed rockfill, and the gap is sealed with a rockfill method, and the rest are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com