Current feed three-inductor boost converter of high frequency transformer connected in delta/Y shape

A technology of high-frequency transformers and three-phase transformers, which is applied in the direction of converting DC power input to DC power output, output power conversion devices, instruments, etc., and can solve the problem of large leakage inductance of high-turn ratio transformers, switching losses, and large leakage inductance of transformers etc. to achieve the effects of reducing input current ripple, balancing heat distribution, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

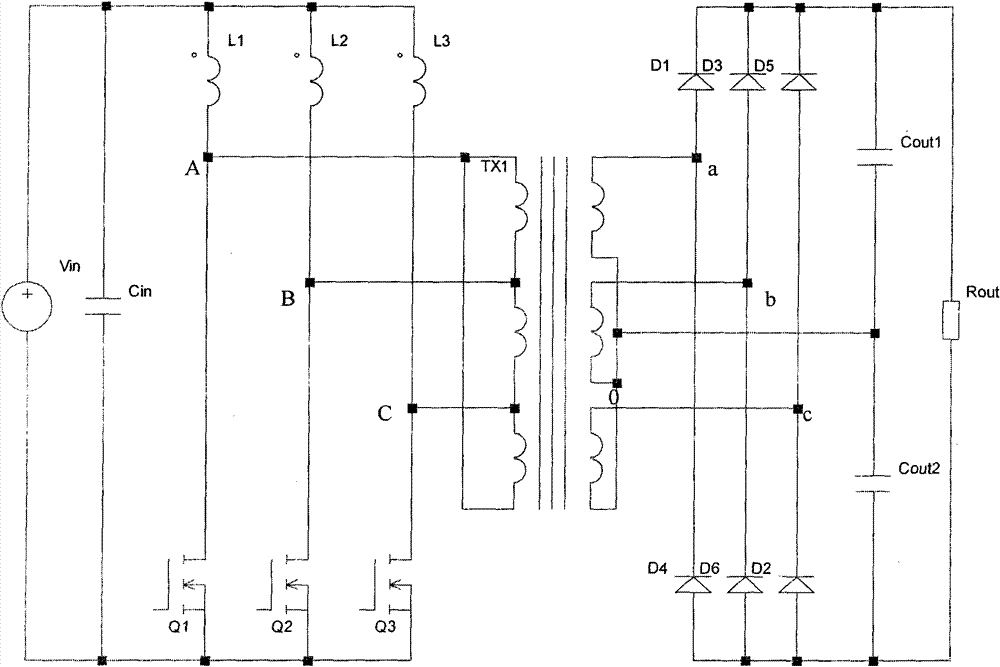

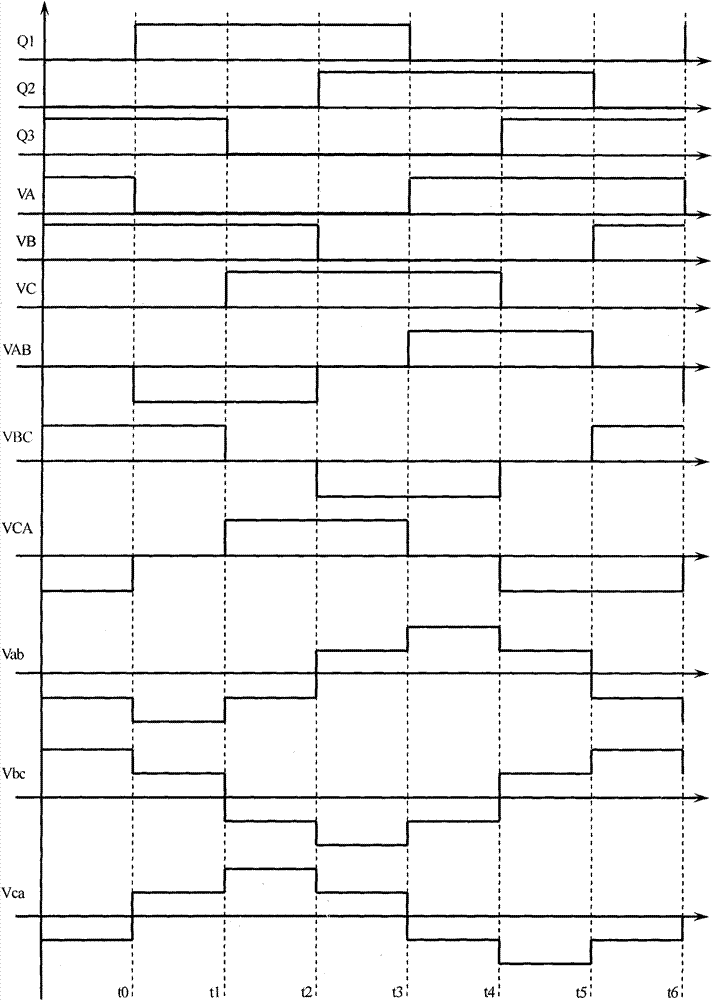

[0010] see figure 1 , the current-fed three-inductance step-up converter of the high-frequency transformer delta-star connection of the present invention includes three power switch tubes Q1, Q2, Q3, and six output rectifier diodes D1, D2, D3, D4, D5, D6 , an input filter capacitor Cin, an output filter capacitor Cout, and a high-frequency three-phase transformer TX1. The primary winding of the high-frequency three-phase transformer is delta-connected and the secondary winding is star-connected. The drain of Q1 is connected to one end of L1 and one end of the primary delta winding of the high-frequency three-phase transformer, the drain of Q2 is connected to one end of L2 and the other end of the primary delta winding of the high-frequency three-phase transformer, and the drain of Q3 is connected to the other end of the primary delta winding of the high-frequency three-phase transformer. One end of L3 is connected to the last end of the delta winding on the primary side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com