Environment-friendly rust inhibiting primer

An anti-rust primer, an environmentally friendly technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as use restrictions, and achieve the effect of harmless to human health and good resolubility resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation technology of environment-friendly antirust primer of the present invention is as follows:

[0031] 1) Disperse slurry: Add hydroxyl resin, film-forming aids, some organic solvents, dispersants, and coupling agents into the dispersion tank, disperse at 1-8m / s for 5-20 minutes, and add pigments and inorganic fillers while stirring , after adding each material, adjust the rotation speed to 2-10m / s, disperse for 20-60 minutes, and obtain the dispersed slurry;

[0032] 2) Grinding: Grind the dispersed slurry with a sand mill for 1 to 5 times, and use a scraper fineness meter to detect the fineness ≤ 60 μm;

[0033] 3) Paint mixing: Put the ground slurry and other remaining materials into the paint mixing tank, stir evenly, and filter.

Embodiment 1

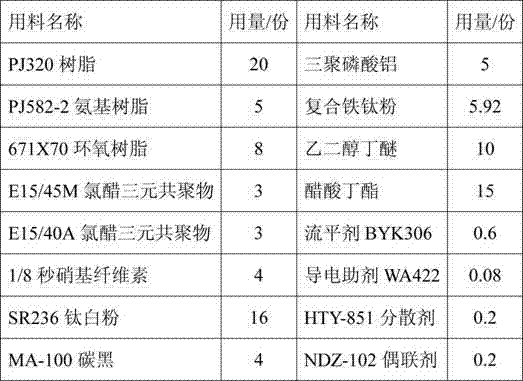

[0035] The composition of the environment-friendly antirust primer is as follows:

[0036]

Embodiment 2

[0038] The composition of the environment-friendly antirust primer is as follows:

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com