Ultra-filtration automatic control system and control method based on membrane structure parameter model

An automatic control system and parameter model technology, which is applied in the field of membrane separation technology and water treatment, can solve the problems of eliminating blindness of membrane fouling, and achieve the effects of ensuring the quality of produced water, prolonging the service life, and controlling membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

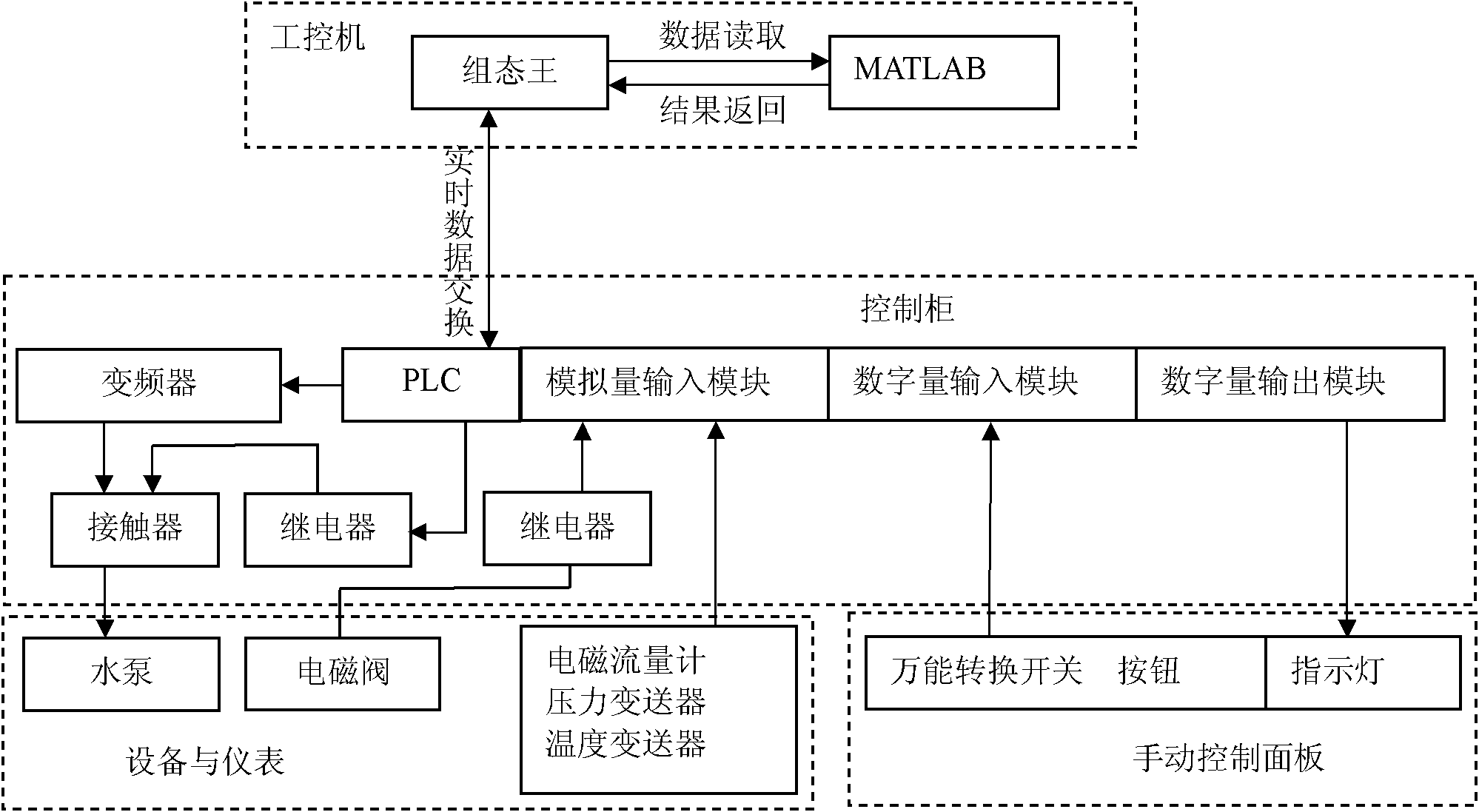

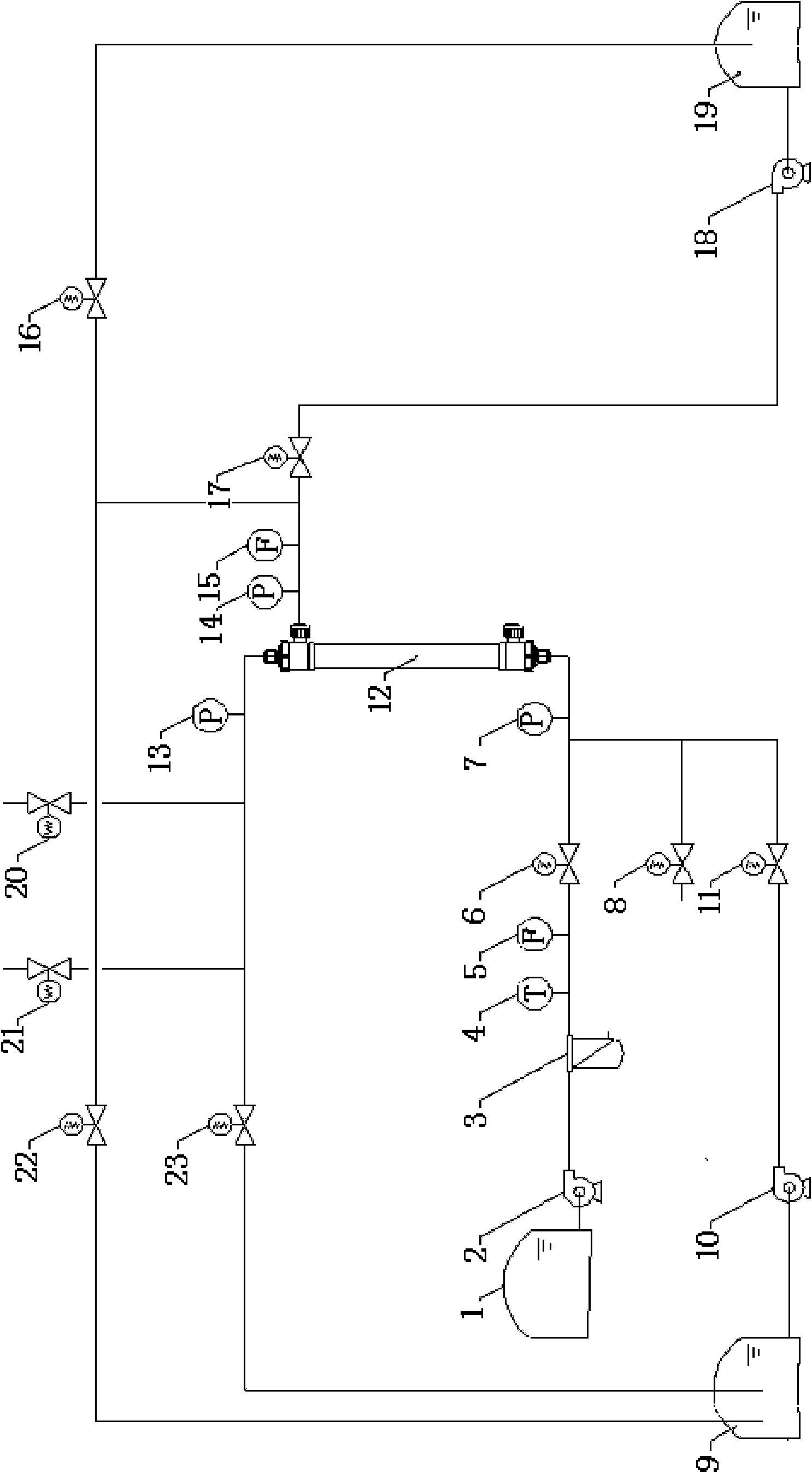

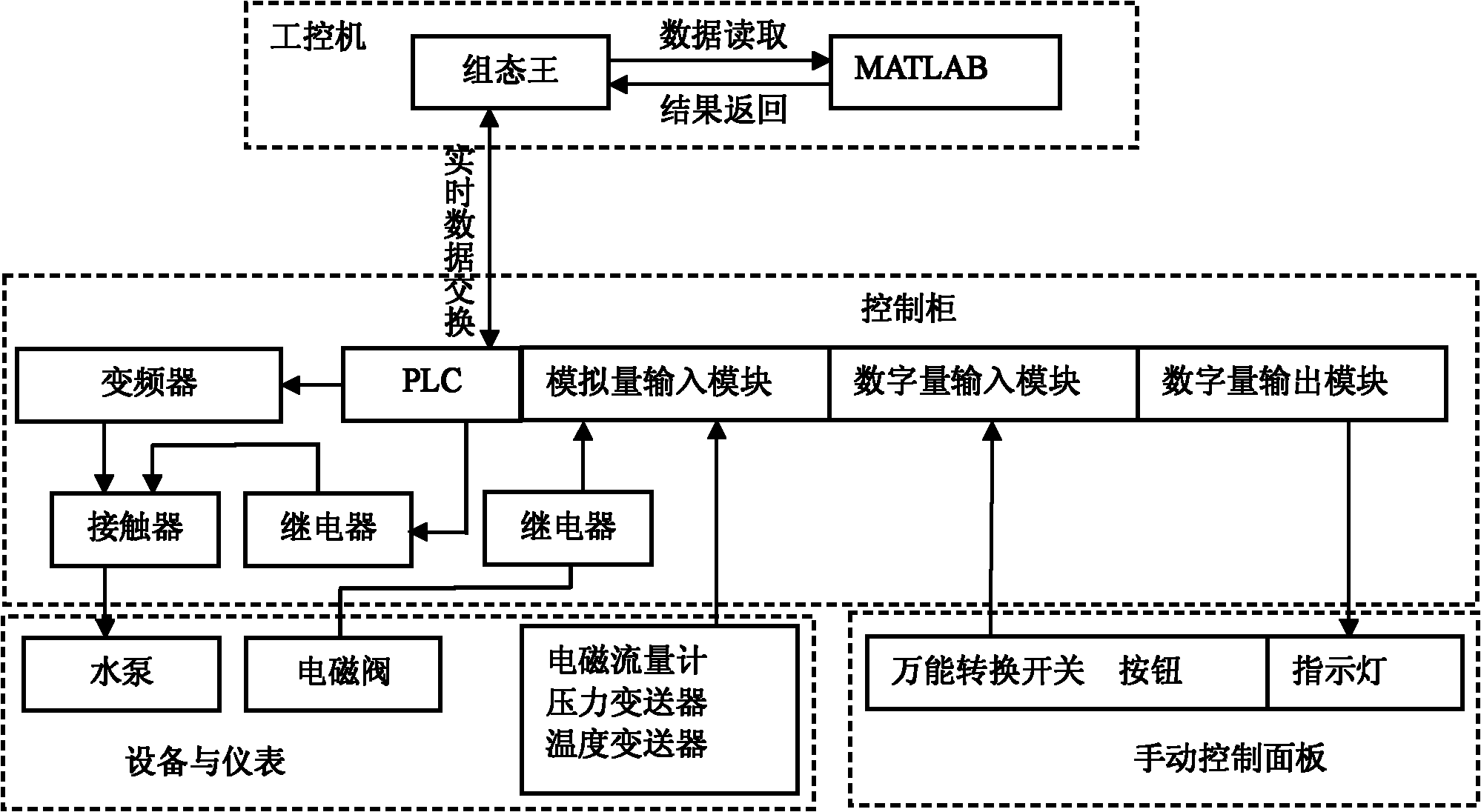

[0042] like figure 1As shown, the ultrafiltration automatic control system based on the membrane structure parameter model includes: industrial cabinet machine, control cabinet, manual control panel, equipment and instruments, wherein: the industrial computer is equipped with Kingview and MATLAB software; used for remote automatic control Fitting with the model; the control cabinet is equipped with PLC, digital input module, digital output module, analog input module and frequency converter; it is used to collect system field data and exchange data with the industrial computer; the manual control panel is equipped with universal conversion Switches, pushbuttons and indicator lamps; for carrying out control programs in manual control mode; equipment and instruments (see figure 2 Shown) comprises hollow fiber membrane module 12 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com