Mineral composite air finishing agent and preparation method thereof

An air treatment agent and mineral technology, applied in chemical instruments and methods, other chemical processes, deodorization, etc., can solve problems such as poor air pollutants effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

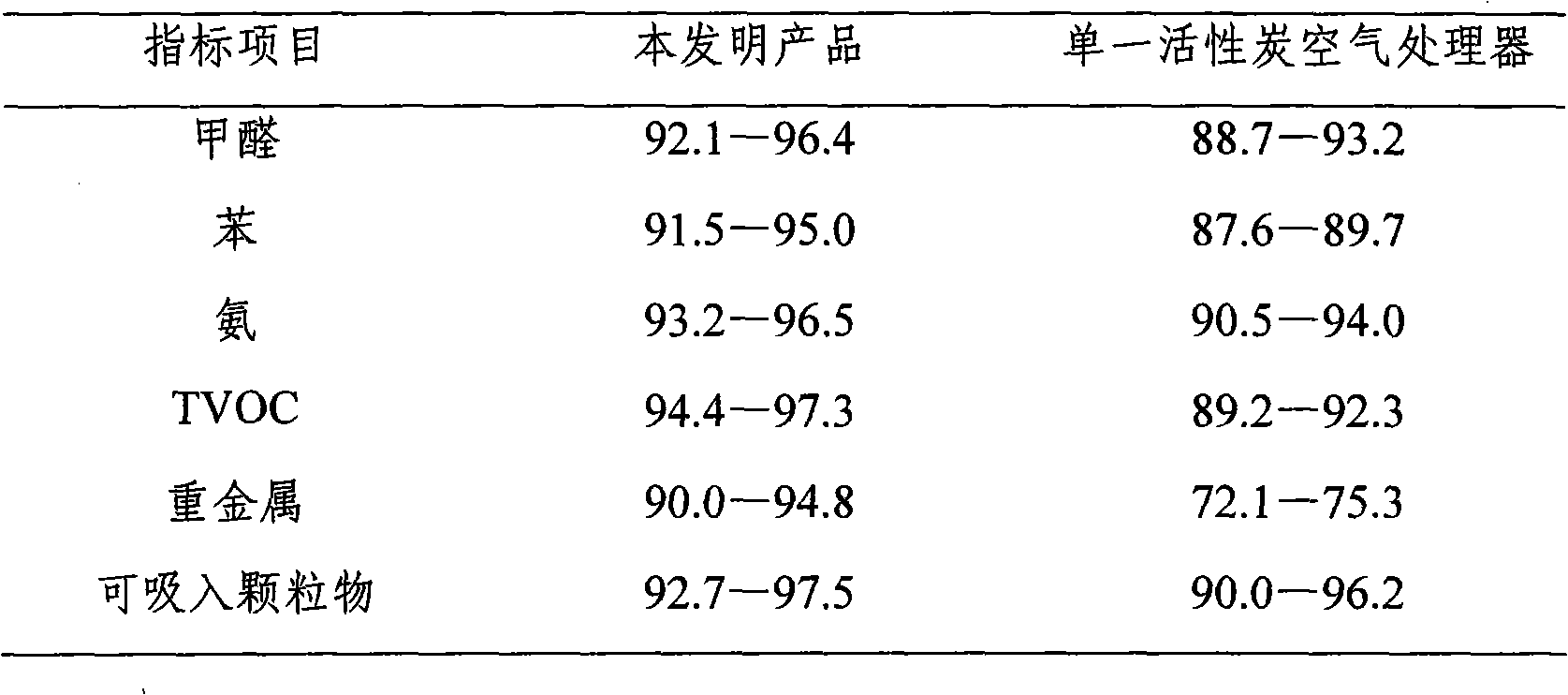

Examples

Embodiment Construction

[0016] The invention provides a mineral composite air treatment agent, which is composed of modified sodium-based bentonite and modified activated carbon, and the weight percentage of the modified sodium-based bentonite in the composite air treatment agent is 30%-60%, The balance is the modified activated carbon, and the modified sodium bentonite is composed of sodium bentonite, iron sulfate, aluminum sulfate and magnesium sulfate, wherein the content of each component in the modified sodium bentonite is :

[0017] Sodium bentonite: 65-75%

[0018] Iron sulfate: 10-15%

[0019] Aluminum sulfate: 10-15%

[0020] Magnesium sulfate: 5-10%.

[0021] The present invention also provides the preparation method of the above-mentioned mineral composite air treatment agent, including a step of weighing raw materials according to weight percentage, including a step of crushing the raw material of sodium bentonite, and melting and burning the raw material of sodium bentonite after crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com