Method for extracting nano-silver in aqueous phase by using ionic liquid

An ionic liquid and water extraction technology, applied in the field of nano-silver, can solve the problems that nano-silver particles are not very mature, the characteristics and laws of nano-silver particles are quite different, and achieve the effects of good application value, mild conditions and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take 2g of dry powder of camphor leaves, add 100mL of deionized water, place in a water-bath shaker, temperature 30°C, rotation speed 180r / min, shake for 5h, take out and cool to room temperature, and vacuum filter to obtain 20g / L of camphor leaf extract .

[0019] Take more than 20mL of cinnamon camphor leaf extract, add 200μL 0.1MAgNO to it 3 Solution, 400 μL 0.1M NaOH solution, magnetically stirred at room temperature, reacted for 6 hours, the reaction was complete, and a silver sol with a concentration of 1 mM was obtained.

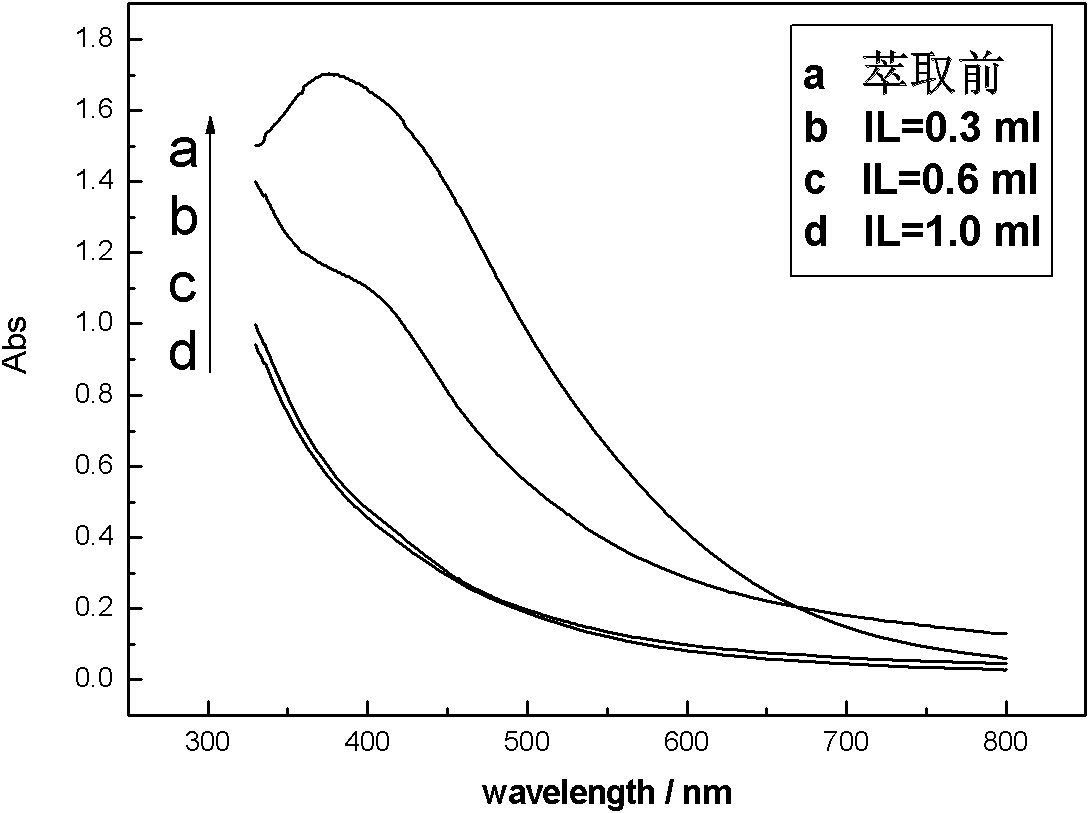

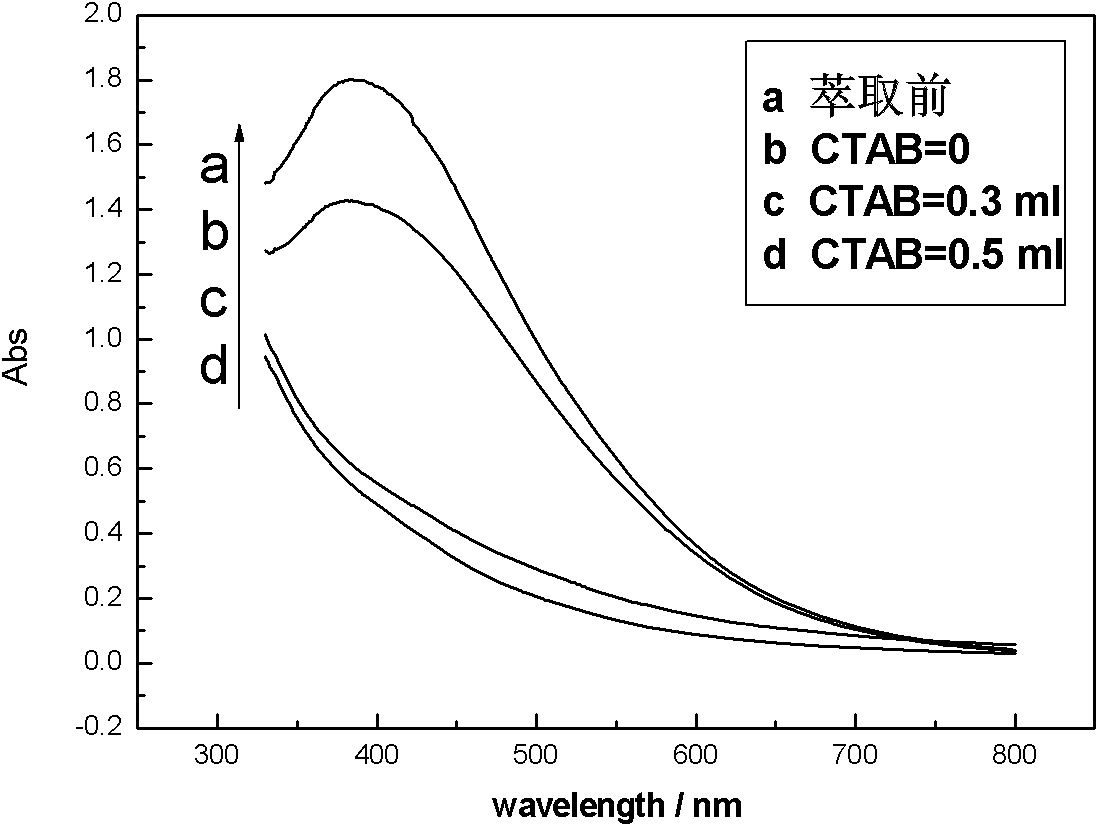

[0020] Take 3 mL of the above-prepared silver sol in a test tube, add 0.5 mL of 30 mM phase transfer reagent cetyltrimethylammonium bromide (CTAB) to it, and then add 0.3 mL of ionic liquid 1-butyl 3-methyl imidazolium hexafluorophosphate ([Bmim][PF 6 ]), vigorously shaken for 10s, the nano-silver in the aqueous phase can be partially extracted into the ionic liquid phase. The UV-Vis spectral scanning pictures of the aqueous phase supernatan...

Embodiment 2

[0022] Get the nano-silver sol that makes in 3mL embodiment 1 in test tube, add the phase-transfer reagent hexadecyltrimethylammonium bromide (CTAB) of 0.5mL30mM wherein, then add 0.6mL ionic liquid 1-butylene therein 3-methylimidazolium hexafluorophosphate ([Bmim][PF 6 ]), vigorously shaken for 10s, all the nano-silver in the water phase can be extracted into the ionic liquid phase. The UV-Vis spectral scanning pictures of the aqueous phase supernatant before and after extraction are shown in figure 1 or figure 2 .

Embodiment 3

[0024] Get the nano-silver sol that makes in 3mL embodiment 1 in test tube, add the phase-transfer reagent hexadecyltrimethylammonium bromide (CTAB) of 0.5mL30mM wherein, add 1.0mL ionic liquid 1-butylene to it again 3-methylimidazolium hexafluorophosphate ([Bmim][PF 6 ]), vigorously shaken for 10s, all the nano-silver in the water phase can be extracted into the ionic liquid phase. The UV-Vis spectral scanning pictures of the aqueous phase supernatant before and after extraction are shown in figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com