Anti-collision guardrail with internally inlaid metal materials

An anti-collision guardrail and metal inlaid technology, which is applied in the direction of fences, roads, climate change adaptation, etc., can solve the problems of plastic guardrails prone to accidents and easy rupture of plastic guardrails, so as to eliminate noise, improve anti-deformation ability, The effect of increasing bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

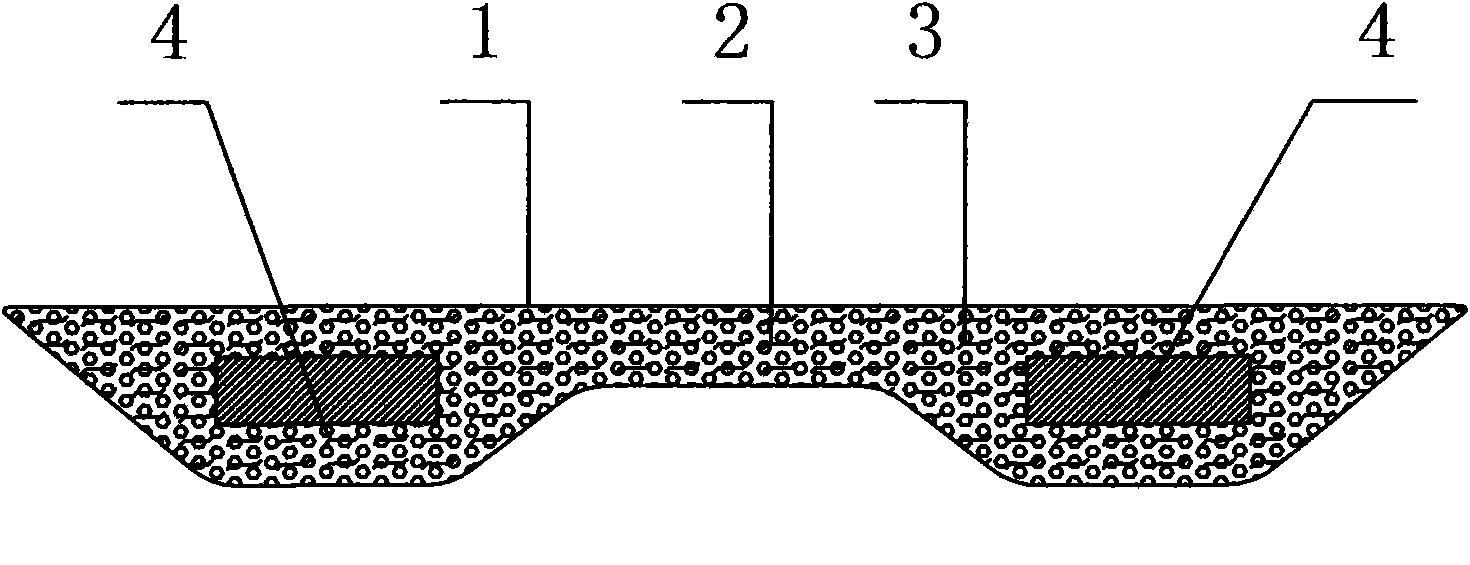

[0028] The end face structure diagram of a W-shaped guardrail embedded with metal material is as follows figure 1 As shown, wherein: 1 is a PVC glass-plastic W-shaped guardrail, 2 is a glass filament, 3 is a hollow glass bead, and 4 is a metal plate. Glass filament 2 and hollow glass microsphere 3 are mixed in the PVC resin, and metal plate 3 is inlaid in the boss hole of the glass-plastic W-shaped guardrail 1 composed of PVC resin, glass filament and hollow glass microsphere through co-extrusion.

[0029] PVC glass plastic material is made by adding hollow glass microspheres and glass filaments to PVC resin. Hollow glass microspheres and glass filaments have excellent corrosion resistance. Hollow glass microspheres can absorb impact energy and reduce weight. Glass filaments prevent W-shaped guardrails from breaking .

Embodiment 2

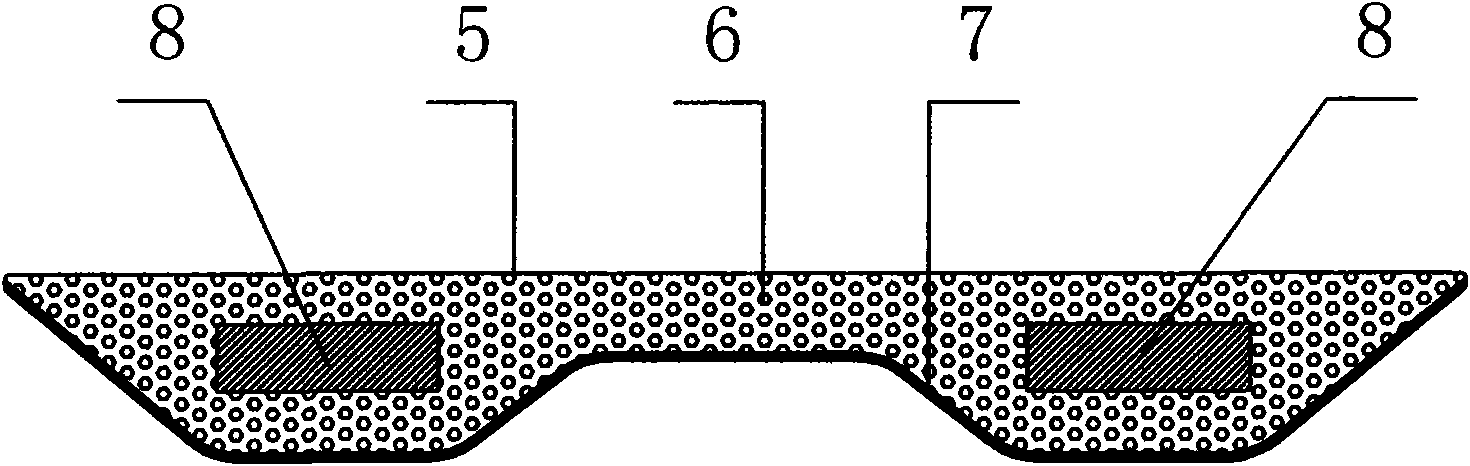

[0031] The end face structure diagram of a W-shaped highway anti-collision co-extruded guardrail embedded with metal material is as follows figure 2 As shown, wherein: 5 is PVC wood-plastic W-shaped guardrail, 6 is wood powder, 7 is ASA self-cleaning material added with nano-titanium dioxide surface layer, and 8 is a metal plate. When manufacturing W-shaped highway anti-collision co-extruded guardrails, one hot extruder extrudes the surface layer ASA self-cleaning material 7 through the die, and the other hot extruder extrudes PVC wood-plastic W-shaped guardrails 5 through the die, metal plate 8 enters the boss hole of PVC wood-plastic W-shaped guardrail 5 through the metal plate conveyor, and the surface layer ASA self-cleaning material 7, PVC wood-plastic W-shaped guardrail 5 and metal plate 8 are cooled and formed in the shaping mold.

[0032] The advantage of this embodiment is: the addition of nano-titanium dioxide surface layer ASA self-cleaning material can effectively...

Embodiment 3

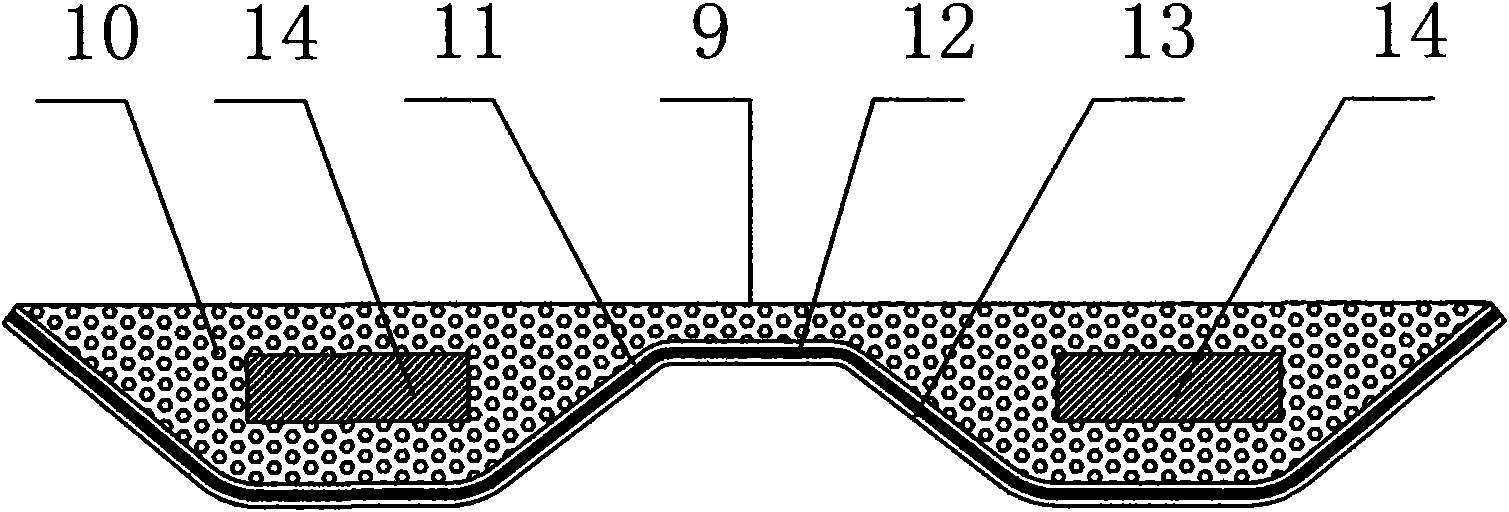

[0034] The structure diagram of the end face of the UV paint inner road guardrail of a W-shaped public light storage-self-luminous material coated with inlaid metal material on the surface is shown in the figure image 3 As shown, wherein: 9 is a PVC wood-plastic W-shaped guardrail, 10 is wood powder, 11 is a bottom UV glue, 12 is a UV glue containing light storage-self-luminous material, 13 is a surface UV protective paint, and 14 is a metal plate. When manufacturing UV paint guardrails that contain light storage-self-luminous materials, first coat the bottom UV glue 11 on the surface of the PVC wood-plastic W-shaped guardrail 9. After ultraviolet light curing, apply UV glue 12 that contains light storage-self-luminous materials. After ultraviolet light curing , be coated with surface layer UV protective paint 13, obtain light storage-self-illuminating UV paint PVC wood-plastic guardrail after cured with ultraviolet light.

[0035] The advantages of this embodiment are: 1. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com