Light-weight and high-intensity wall plate

A high-strength, wall panel technology, used in building components, buildings, building structures, etc., can solve the problems of poor thermal insulation, sound insulation, poor thermal insulation performance, insufficient strength, and low practicability, and achieves convenient production and installation. Quick, simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

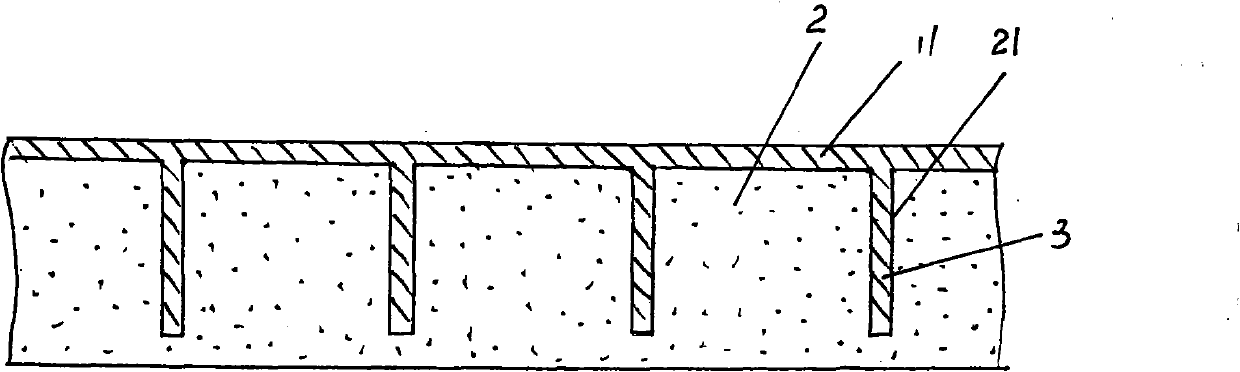

[0017] see figure 1 , a lightweight high-strength wall panel, including a panel 1 and a lightweight sandwich filling panel 2, the panel 1 includes an upper panel 11, a lower panel 12, and the lightweight sandwich filling panel 2 is located on the upper panel 11 and the lower panel 12, the material of the lightweight sandwich filling board 2 is not subject to any restrictions, preferably XPS extruded polystyrene foam board, EPS expandable polystyrene foam board, or It is hydrophobic rock wool board and so on. A plurality of reinforcing rib holes 21 are provided from top to bottom in the thickness direction of the lightweight sandwich filling panel 2, and the plurality of reinforcing rib holes 21 are arranged at intervals on the lightweight sandwich filling panel 2. The reinforcing rib holes 21 may be a through hole or a blind hole, and a through hole is selected in this embodiment. The hole shape of the reinforcing rib hole 21 is not limited in any way, and may be a circular,...

Embodiment 2

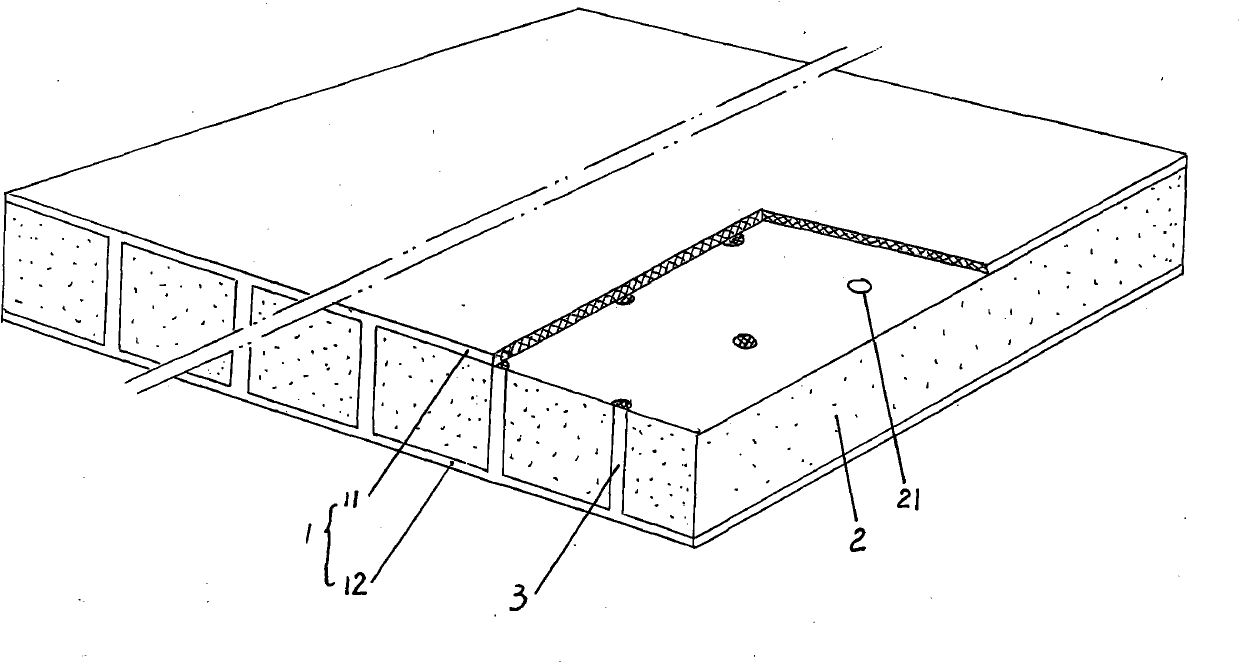

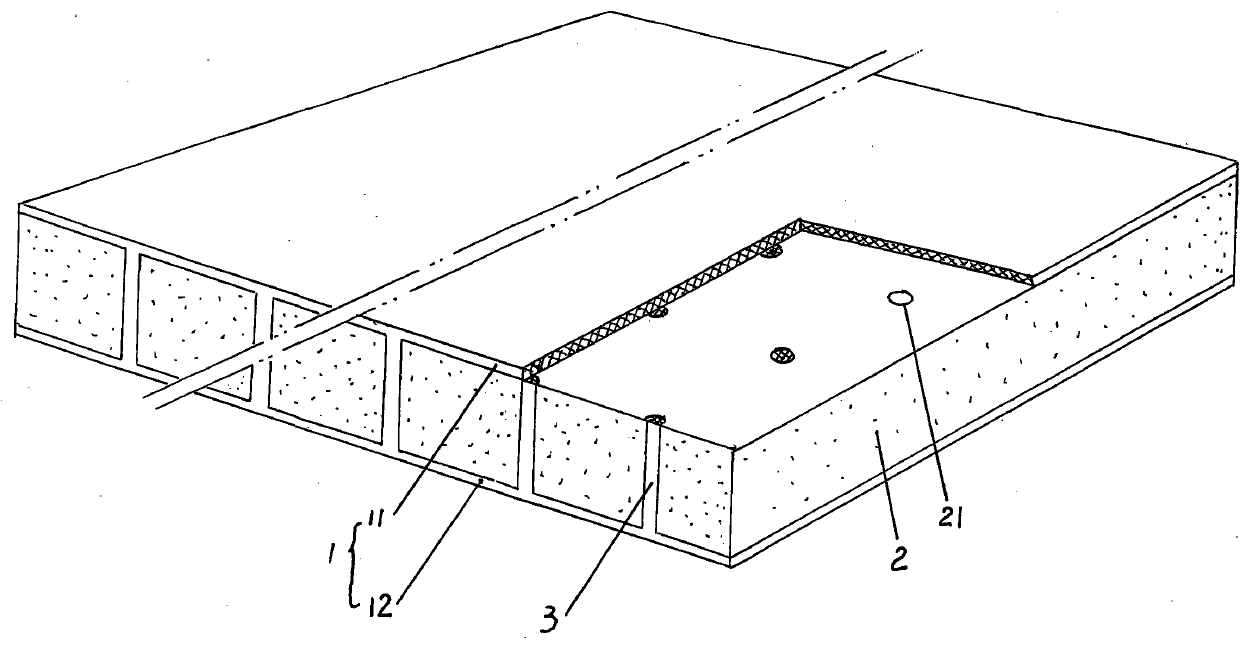

[0020] See figure 2 , in this embodiment, the panel 1 only includes the upper panel 11, the lightweight sandwich filler panel 2 is located below the upper panel 11, the reinforcing rib hole 21 is a blind hole, and the reinforcing Rib 3 is located in the blind hole and connected with said upper panel 11 . All the other are the same as the description of embodiment 1.

[0021] Combine below figure 2 Briefly describe the manufacturing process of this embodiment: first, the material with the rib hole 21 preset is an XPS extruded polystyrene foam board, an EPS expandable polystyrene foam board, or a hydrophobic rock wool board. The lightweight sandwich filling board 2 is placed on a plane; then, magnesium oxide cement, magnesium chloride cement or magnesium oxychloride cement is selected as the cementitious material, and a small amount of inert stone powder, light powder such as wood fiber powder, chlorine The mixed material and water are mixed in a fluid state, and then the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com