Method for preparing activated carbon from peeled branch wood of initiated branches in eucommia bark leaf forest

A technology of Eucommia ulmoides leaf forest and activated carbon, which is applied in the field of activated carbon manufacturing, can solve the problems of high cost of activated carbon with high adsorption performance and high preparation cost of guided activated carbon, and achieve the effects of shortening impregnation time, promoting comprehensive development and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

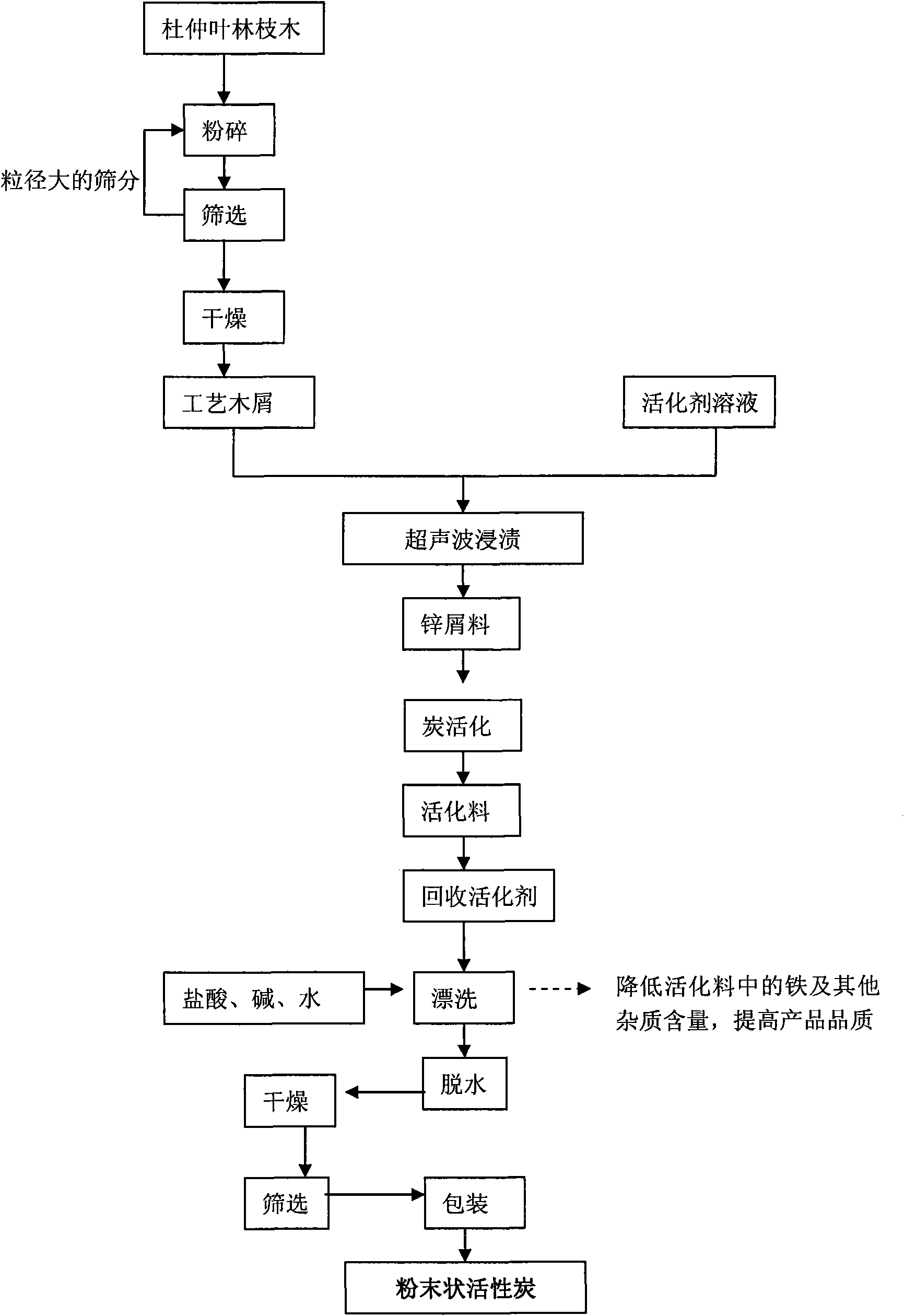

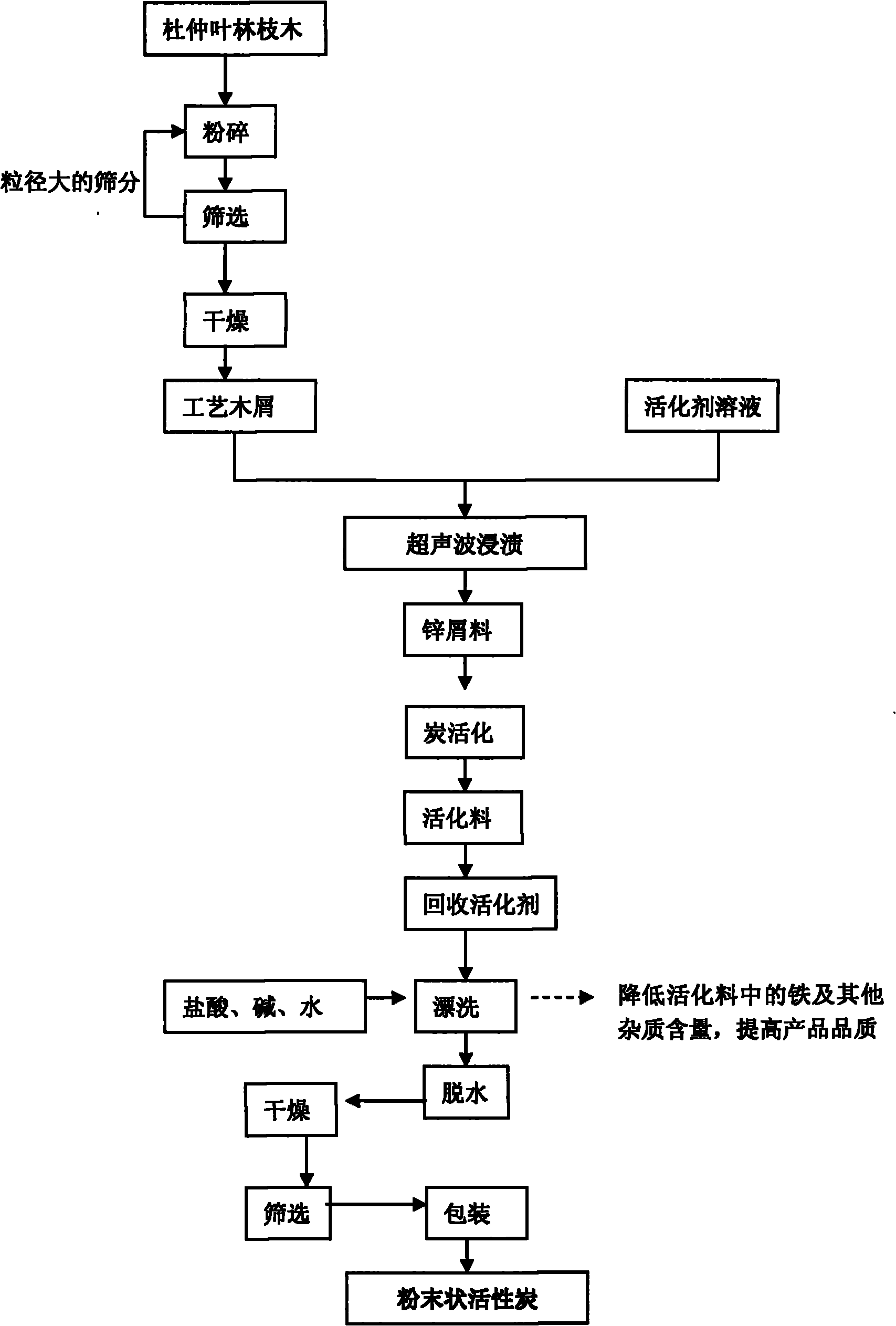

[0022] In order to further illustrate the present invention, in conjunction with accompanying drawing, give an embodiment below: be the method for activator manufacture gac with zinc chloride:

[0023] (1) pretreatment stage: the leaf forest branch wood after peeling, be pulverized to 20~40 order, dry, make moisture content be lower than 15%-20%, get 500 grams, and 2000 grams zinc chloride solution (mass concentration is 50%, pH 2) Mixed with a material-to-liquid ratio of 1:4, soaked by ultrasonic vibration for 5 hours, and accelerated kneading.

[0024] (2) Charcoal activation reaction: Using the zinc scrap obtained in the pretreatment stage as the raw material, the carbon is activated at a temperature of 700°C for 2 hours, so that the pore structure of the raw material is gradually developed and finally becomes activated carbon.

[0025] (3) The post-treatment stage of preparing activated carbon: ① Recover the activator solution; ② Rinse the activated material 3 to 6 times t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com