Slag splashing furnace protecting material and preparation method thereof

A technology for protecting furnace and magnesite by slag splashing, which is applied in the field of slag splashing and furnace protection and its preparation, can solve the problems of energy saving, consumption reduction, incompatibility with the development trend of high efficiency, etc., so as to facilitate furnace protection and increase wettability. , the effect of increasing the melting temperature and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of slag-splashing furnace protection material is prepared by the following steps:

[0033] (1) Mix the proportioned raw materials according to the formula: 28% of magnesite; 41% of lightly burned magnesium powder; 10% of magnesium powder; 15% of silicon micropowder; ; Wherein the chemical composition in magnesite is calculated by weight percentage, MgO 38-45%, SiO 2 1-2%, CaO 1-2%, and the rest are impurities; the chemical composition of light-burned magnesium powder is calculated by weight percentage, MgO 90-95%, SiO 2 0.5-1%, CaO 0.5-1.5%, the rest are impurities;

[0034] (2) Mixing and crushing the raw materials mixed in step (1) until the particle size is less than 3mm;

[0035] (3) Add an appropriate amount of water to the mixture prepared in step (2) (the addition of water does not have a chemical effect on the mixture, it is only for granulation needs, it can be based on the actual extrusion granulation needs, the technology in the field The person...

Embodiment 2

[0037] A kind of slag-splashing furnace protection material is prepared by the following steps:

[0038] (1) Mix the proportioned raw materials according to the formula: 25% magnesite; 45% lightly burned magnesium powder; 12% magnesium powder; 12% silicon micropowder; 2.5% nano-scale titanium dioxide; C; wherein the chemical composition of magnesite is calculated by weight percentage, MgO 38-45%, SiO 2 1-2%, CaO 1-2%, and the rest are impurities; the chemical composition of light-burned magnesium powder is calculated by weight percentage, MgO 90-95%, SiO 2 0.5-1%, CaO 0.5-1.5%, the rest are impurities;

[0039] (2) Mixing and crushing the raw materials mixed in step (1) until the particle size is less than 3mm;

[0040] (3) Add water to the mixture prepared in step (2) to granulate, then dry and sieve the particles with a particle size of 10-40 mm to obtain the slag-splashing furnace charge.

Embodiment 3

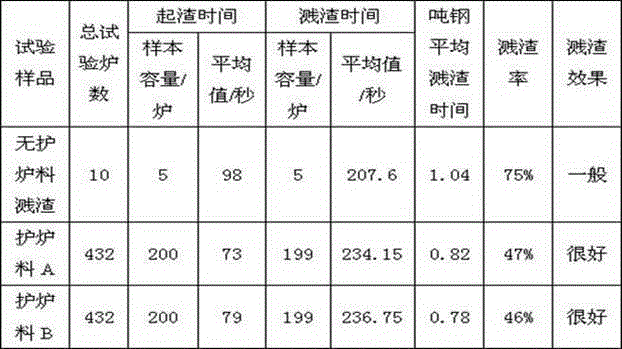

[0042] The slag-splashing furnace protection material obtained in Example 1 is called furnace protection material A, and the slag-splashing furnace protection material obtained in Example 2 is called furnace protection material B, wherein the test of furnace protection material A is selected as the 7# converter of a certain iron and steel plant, and the furnace protection material For the test of B, the 3# converter of a steel plant was selected, and the slag splashing test was carried out according to the following contents:

[0043] The 7# converter and the 3# converter were tested 432 times respectively. Among them, 210 furnaces were splashed with slag, and a total of 89.52 tons of protective materials were used, with an average of 426.31 kg of protective materials used in each furnace. It was carried out in four stages. The details are as follows:

[0044] In the first stage of the test, since the 7# converter and the 3# converter have just completed the thermal replacement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com