Method for preparing coal gangue perforated brick by taking high-calcium graphite milltailing sand as filler

A technology of tailings sand and porous bricks, applied in applications, ceramic products, household utensils, etc., can solve the problems of waste, environmental pollution, low plasticity, etc., and achieve the effects of reducing land occupation and storage, saving resources, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

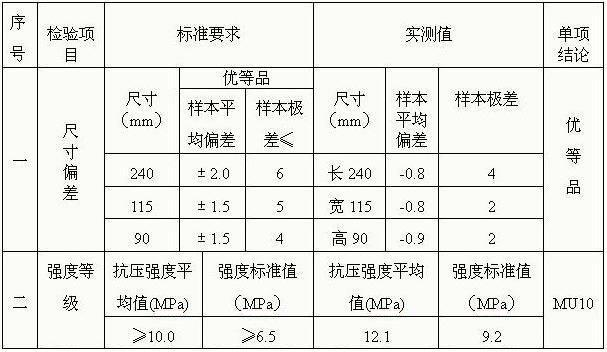

Image

Examples

specific Embodiment approach 1

[0010] Specific implementation mode 1: In this embodiment, the method of using high-calcium graphite dressing tailings sand as a filler to make gangue porous bricks is carried out in the following steps: 1. The high-calcium graphite dressing tailings sand, high-silicon gangue and shale gangue are used according to the mass percentage. Mix and grind until the particle size of more than 65% is not greater than 0.5mm, add water until the water content is 15%-17%, and perform a stirring; 2. Aging the product after the first stirring in the aging warehouse for at least 72 hours, add water to the water content 14%-16%, the second stirring; third, the product after the second stirring is sent to the mixing extruder, and water is added until the water content is 16%, and the third stirring is carried out; the fourth and third stirring products are extruded in a vacuum Vacuum forming in the brick machine; 5. Stacked blanks, dried in a drying kiln until the water content is less than 5%,...

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the high-calcium graphite beneficiation tailings sand described in step one accounts for 30% of the total mass of the mixture, the high-silicon gangue accounts for 35% of the total mass of the mixture, and the shale Gangue accounts for 35% of the total mass of the mixture. Others are the same as the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the content of CaO in the high-calcium graphite beneficiation tailings sand is 11%, the content of MgO is 2%; the content of silicon in the high-silicon gangue is 40% . Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com