Preparation method of multifunctional liquid membrane sand-fixing agent

A kind of sand-fixing agent and multi-functional technology, applied in the field of preparation of new multi-functional liquid film sand-fixing agent, can solve the problems of difficult cost, single material, inconvenient construction and operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

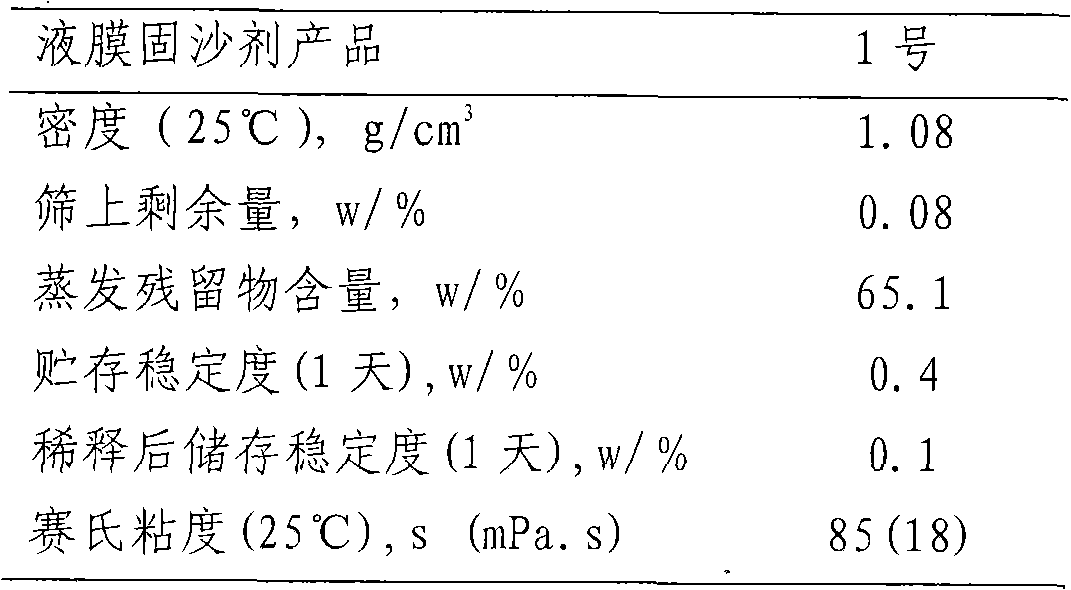

[0007] Take a certain bitumen (viscosity (80°C) 4000mm 2 / s, density 0.975cm 3 / g, softening point 41 ° C, H / C atomic ratio 1.56, bentonite, water glass, polyvinyl alcohol (relative molecular mass 2000) as raw materials, mass ratio is 1: 0.1: 0.1: 0.1; heated to 120 ° C; The emulsifier sodium dodecylbenzenesulfonate and the functional additive component naphthenate are formulated into an aqueous solution at a concentration of 0.1% to 0.4%, heated to 40°C, and emulsified with a colloid mill at an oil-water ratio of 60:40 to obtain Liquid film sand-fixing agent, test results are shown in Table 1.

[0008] Table 1 Test results of No. 1 liquid film sand-fixing agent

[0009]

[0010] The liquid film sand fixing agent has room temperature storage stability for 60 days without demulsification. The liquid film sand-fixing agent was used in the southeast margin of the Tengger Desert. The tests of fixing mobile sand dunes with sand-fixing agent alone; the combination of sand-fixi...

Embodiment 2

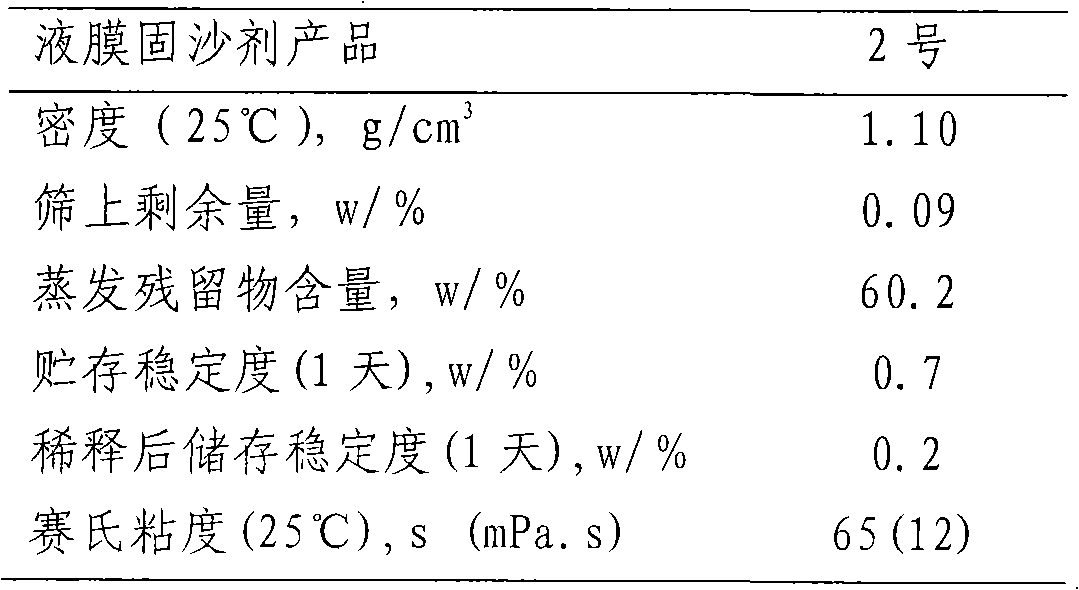

[0012] Take a certain bitumen (viscosity (80°C) 3000mm 2 / s, density 0.98cm 3 / g, softening point 40°C, H / C atomic ratio 1.58, bentonite, water glass, polyvinyl alcohol (relative molecular mass 3000) as raw materials, the mass ratio is 1:0.15:0.05:0.15; heated to 120°C; emulsified Agent sodium dodecylbenzene sulfonate, OP~10 and functional additive component lignite humic acid are prepared into aqueous solution with the concentration of 0.1%, 0.1% and 0.4% respectively and heated to 50 ℃, use colloid mill to oil-water ratio 60: 40 for emulsification to obtain a liquid film sand-fixing agent. The test results are shown in Table 2.

[0013] Table 2 Test results of No. 2 liquid film sand-fixing agent

[0014]

[0015] The liquid film sand fixing agent has room temperature storage stability for 60 days without demulsification. The liquid film sand-fixing agent was used on the southern edge of the Tengger Desert. The tests of fixing mobile sand dunes with sand-fixing agent al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com