Metal halide lamp power supply and method for lighting metal halide lamp

A halogen lamp and metal technology, applied in the field of metal halide lamp power supply and lighting the metal halide lamp based on the metal halide lamp power supply, can solve the problem of unstable power frequency transformer power supply, inconvenient installation, transportation and maintenance, and low efficiency of transformer power supply and other issues, to achieve significant power-saving effects, light weight, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

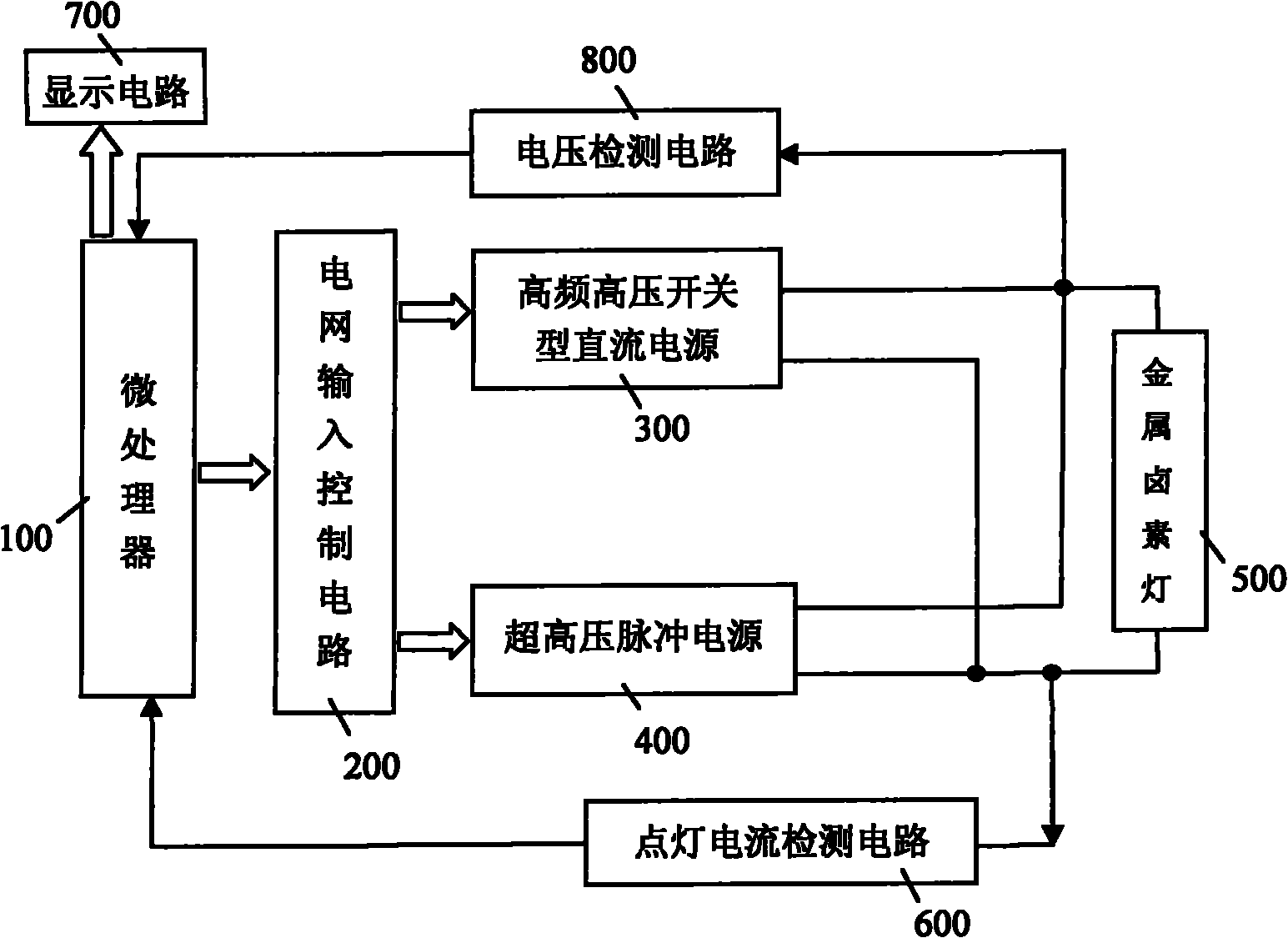

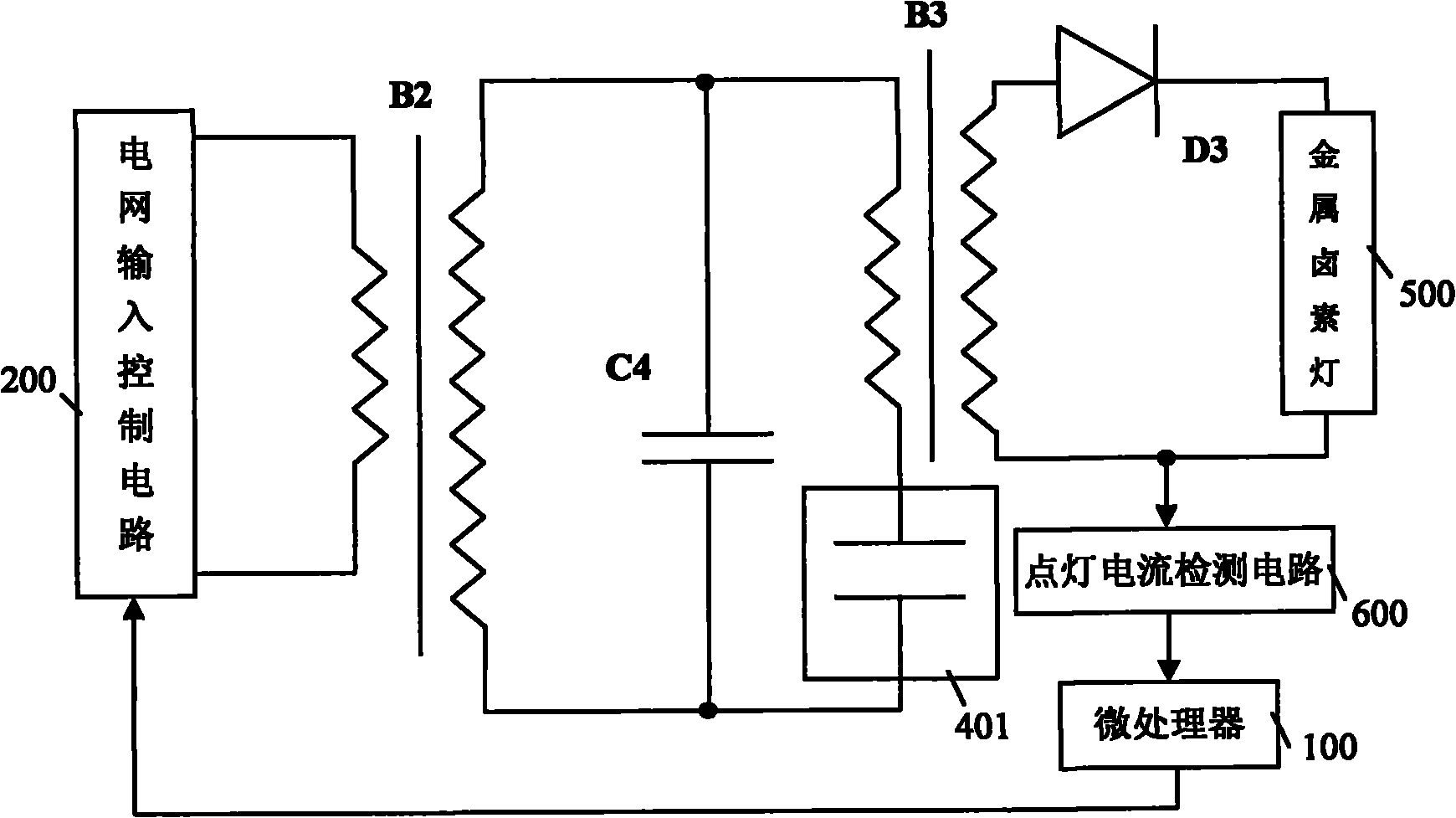

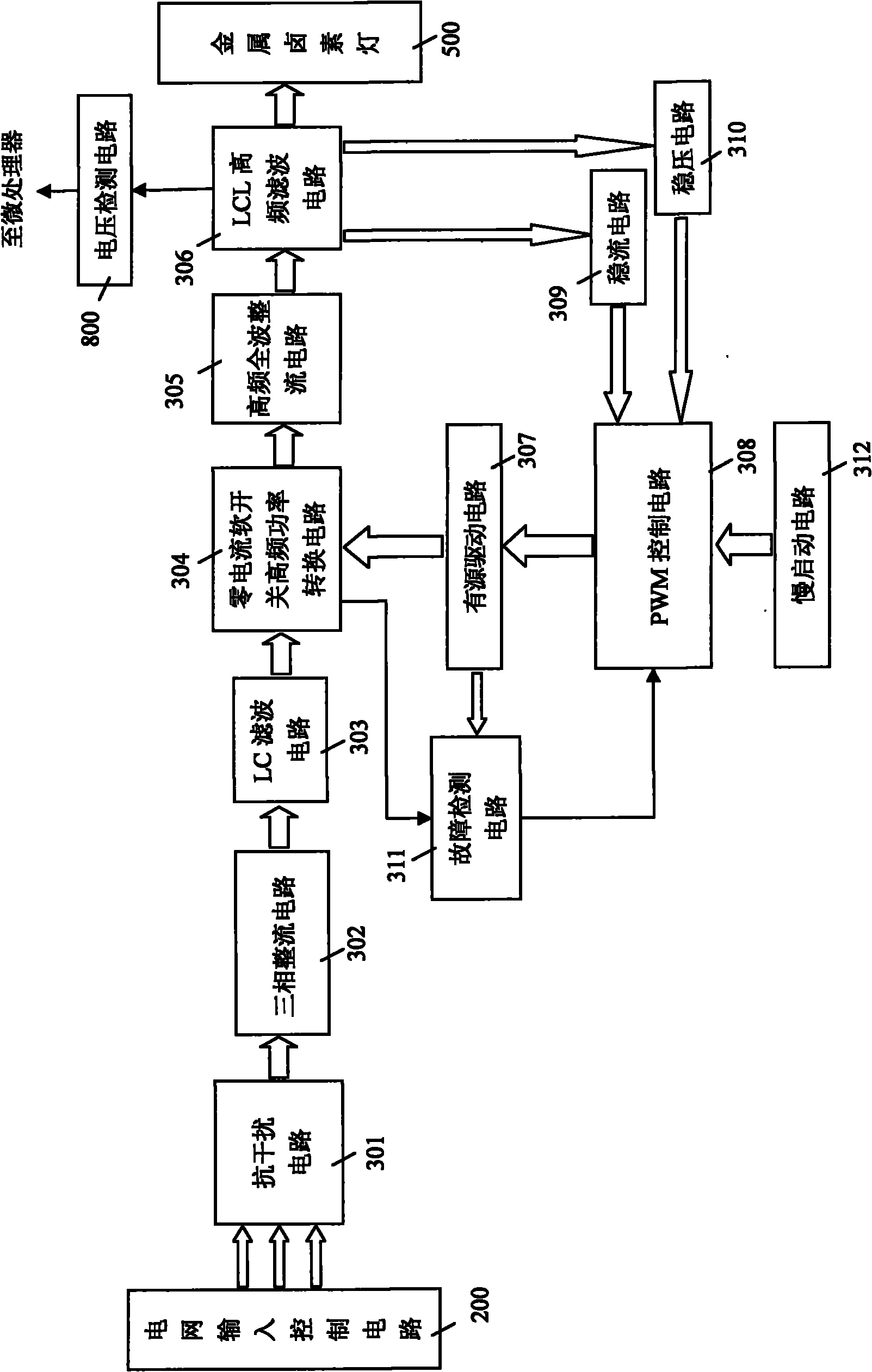

[0023] like figure 1 , the metal halide lamp power supply of the present invention includes a microprocessor 100 (such as Image 6 ), a high-frequency high-voltage switching DC power supply 300, an ultra-high voltage pulse power supply 400, a lighting current detection circuit 600, and a voltage detection circuit 800. The signal output terminal of the microprocessor 100 is respectively connected to the input terminal of the high-frequency high-voltage switching DC power supply 300 and the input terminal of the ultra-high voltage pulse power supply 400 via the grid input control circuit 200. The high-frequency high-voltage switching DC power supply 300 The output end of the ultra-high voltage pulse power supply 400 is connected to the metal halide lamp 500, that is, the high-frequency high-voltage switching DC power supply 300 and the ultra-high voltage pulse power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com