Brake clamp heat insulation plate and preparation method thereof

A technology of brake caliper and heat shield, applied in the field of brake caliper heat shield and its preparation, can solve the problem of low heat resistance temperature and compressive strength of the heat shield, which cannot meet the requirements of the brake caliper heat shield. Requirements for heat resistance temperature and compressive strength, etc., to achieve high compressive strength, low thermal expansion, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of raw materials:

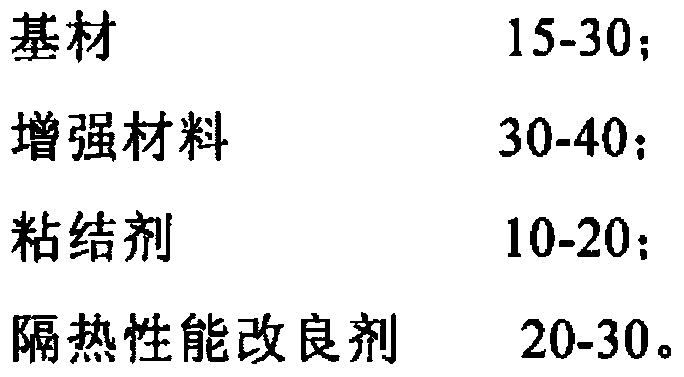

[0028] components

weight percentage

Epoxy modified phenolic resin

10%

Iron oxide yellow

25%

Barite

30%

35%

[0029] 2. Preparation:

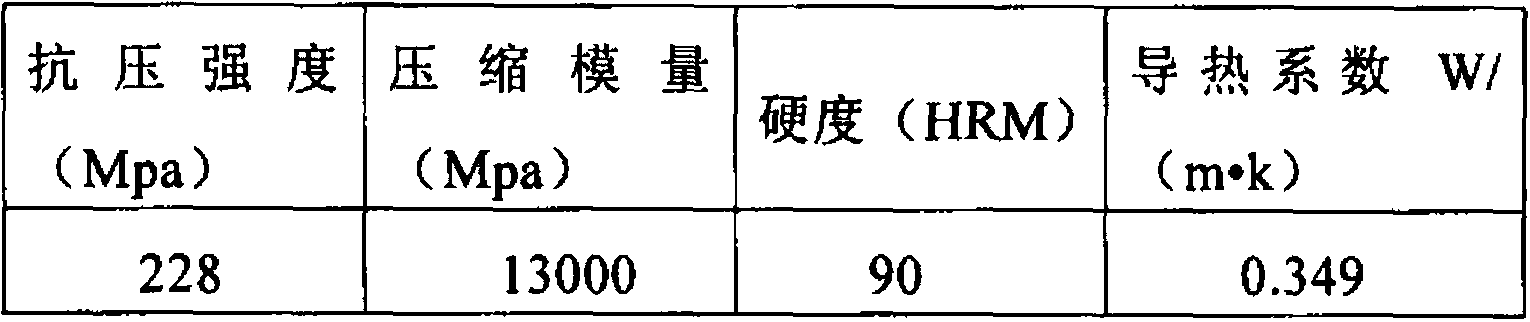

[0030] Add the above-mentioned base materials, binders and heat insulation performance improvers to the high-speed rake mixer in proportion and mix them. The mixing time is controlled to be 2 minutes, and then the reinforcing materials are added in proportion to the high-speed rake mixer. Mix in the middle, control the mixing time to 2min, then spray alcohol, and then dry in the dryer. Place the obtained mixed material in a molding mold, control the molding temperature to 120°C, and the molding pressure to 300kg / cm 2 Press for 300s. Then, the formed heat shield is sintered at high temperature, the sintering temperature is controlled at 120° C., and the sintering time is 12 hours. After cooling the sintered heat shield to roo...

Embodiment 2

[0035] 1. Preparation of raw materials:

[0036] components

weight percentage

Cashew nut shell oil modified phenolic resin

15%

30%

15%

40%

[0037] 2. Preparation:

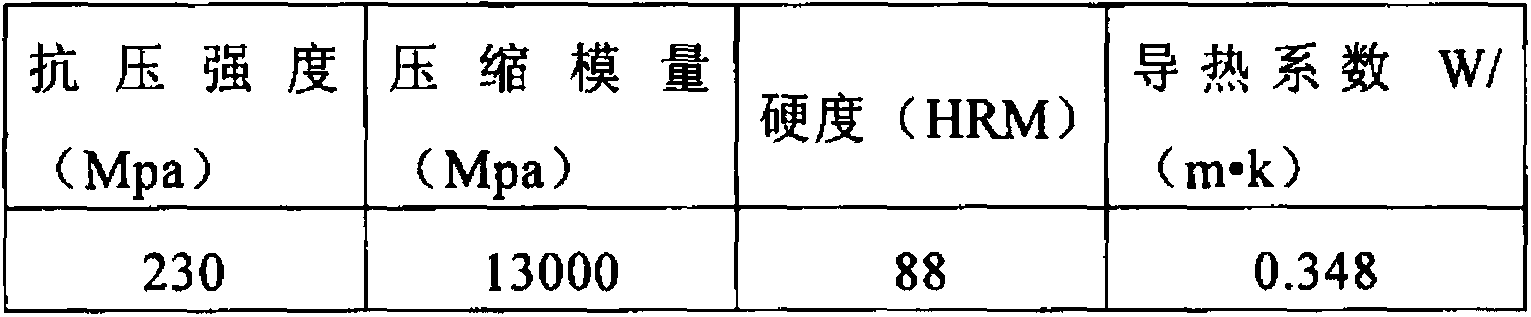

[0038] Add the above-mentioned base materials, binders and heat insulation performance improvers to the high-speed rake mixer in proportion to mix, control the mixing time to 3min, and then add the reinforcing materials to the high-speed rake mixer in proportion Mix in the middle, control the mixing time to 1min, then spray alcohol, and then dry in the dryer. Place the obtained mixed material in a molding mold, control the molding temperature to 140°C, and the molding pressure to 450kg / cm 2 Press for 250s. Then the formed heat shield is sintered at high temperature, the sintering temperature is controlled to be 100°C, and the sintering time is 20h. After cooling the sintered heat shield to room temperature, machin...

Embodiment 3

[0043] 1. Preparation of raw materials:

[0044] components

weight percentage

Silicone modified phenolic resin

12%

[0045] Iron Oxide Red

27%

Clay

23%

38%

[0046] 2. Preparation:

[0047] Add the above-mentioned base materials, binders and heat insulation performance improvers to the high-speed rake mixer in proportion to mix, control the mixing time to 4min, and then add the reinforcing materials to the high-speed rake mixer in proportion Mix in the middle, control the mixing time to 1min, then spray alcohol, and then dry in the dryer. Put the obtained mixed material in a molding mold, control the molding temperature to 135°C, and the molding pressure to 350kg / cm 2 Press for 350s. Then sinter the formed heat insulation board at high temperature, control the sintering temperature to 140° C., and the sintering time to 30 h. After cooling the sintered heat shield to room temperature, mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com