Pigment composition for red color filter, method for producing the same, color composition using the same, and color filter

A technology for pigment compositions and compounds, applied in chemical instruments and methods, instruments, filters, etc., can solve the problems of low yield, poor processing resistance, etc., and achieve the effect of high contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0297] (Preparation of Coloring Composition)

[0298] In order to disperse the diketopyrrolopyrrole pigment composition of the present invention in the pigment carrier, various dispersing devices such as a three-roll mixer, a two-roll mixer, a sand mill, and a kneader can be used. In addition, in order to disperse these well, dispersion aids such as various surfactants and pigment derivatives may be added as appropriate. By using a dispersing assistant, it is possible to prepare a coloring composition that is excellent in the dispersion of the pigment and prevents re-agglomeration of the dispersed pigment.

[0299] In addition to the diketopyrrolopyrrole pigment of the present invention, red pigments, yellow pigments, dyes, antioxidants, polymerization inhibitors, leveling agents, humectants, viscosity regulators, etc. additives, preservatives, antibacterial agents, surfactants, anti-caking agents, ultraviolet absorbers, infrared absorbers, fillers or conductive materials and...

Embodiment 1

[0315] (first process)

[0316] In a stainless steel reaction vessel with a reflux tube, 200 g of tert-amyl alcohol dehydrated with molecular sieves and 140 g of sodium tert-amyloxide were added under a nitrogen atmosphere, and heated to 100° C. while stirring to prepare an alkoxide solution.

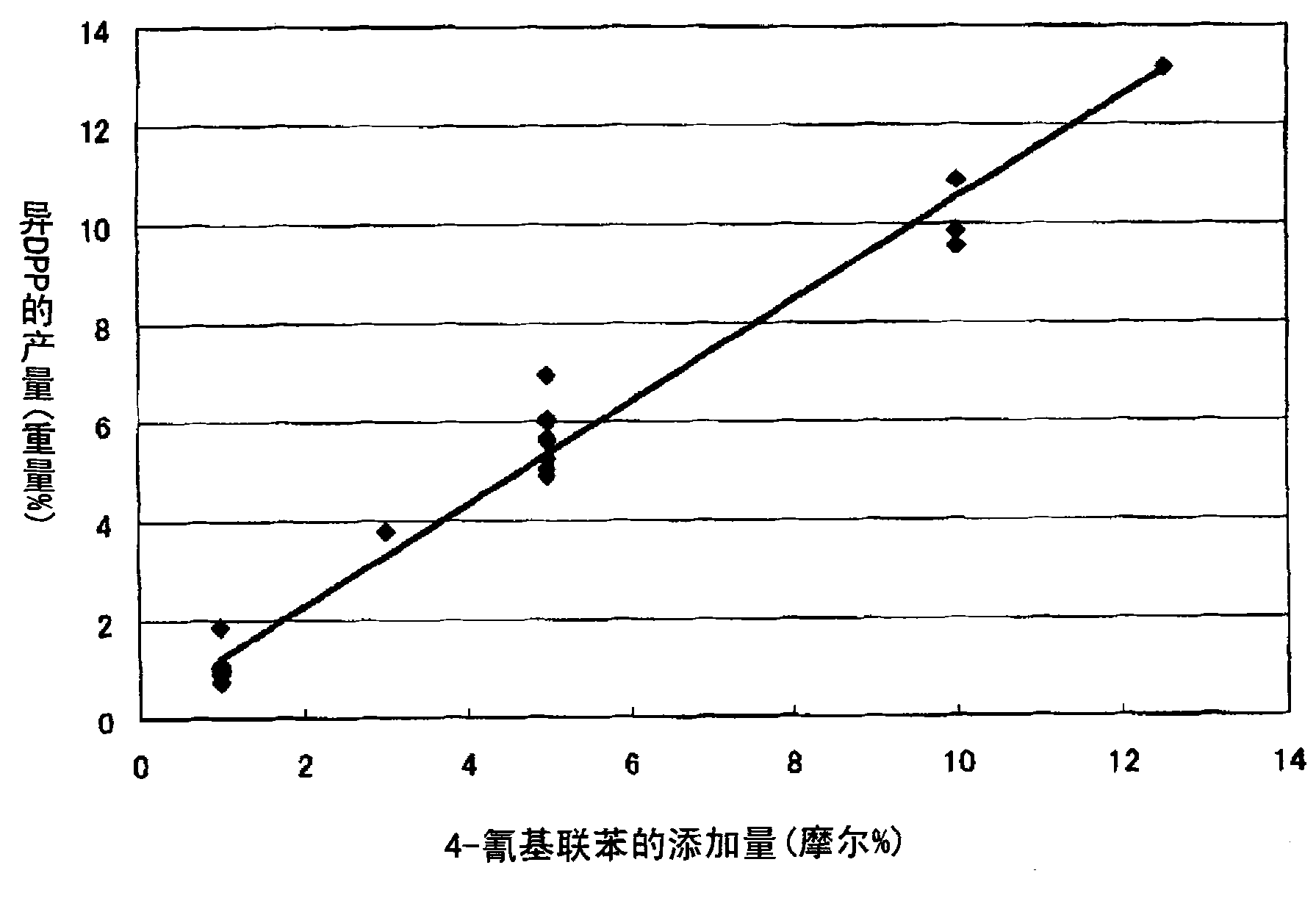

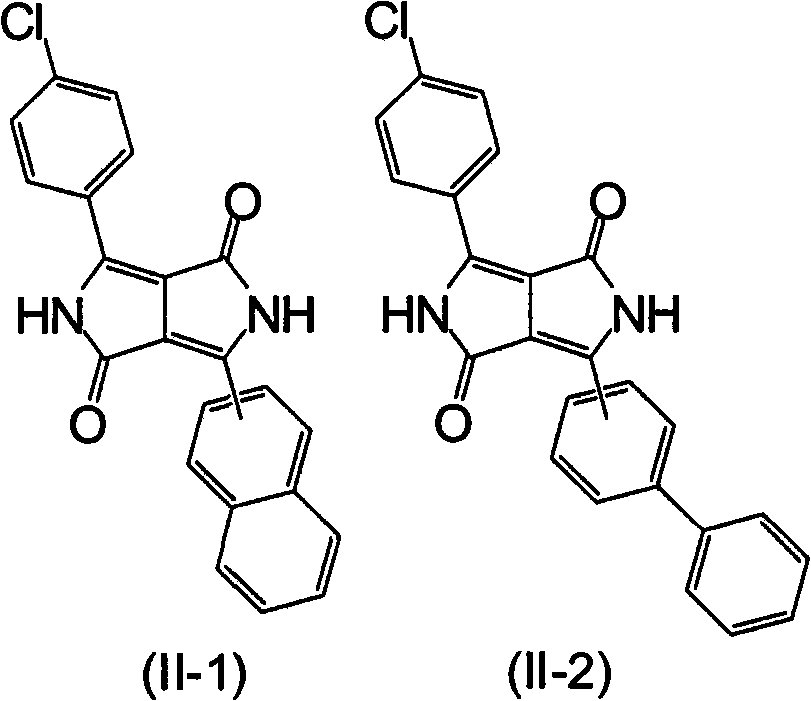

[0317]On the other hand, 88 g of diisopropyl succinate, 97.0 g of 4-chlorobenzonitrile, and 3.9 g of 4-cyanobiphenyl were added to a 500 mL glass flask, and heated to 90°C while stirring to dissolve them. Solutions of these mixtures were prepared. While vigorously stirring, the heated solution of this mixture was slowly added dropwise to the above-mentioned alkoxide solution heated to 100° C. at a constant speed over 2 hours. After completion of the dropwise addition, heating and stirring were continued at 90° C. for 2 hours to obtain an alkali metal salt of a diketopyrrolopyrrole pigment composition.

[0318] Furthermore, 600 g of methanol, 600 g of water, and 304 g of acetic acid we...

Embodiment 2

[0323] 97.0 g of 4-chlorobenzonitrile and 3.9 g of 4-cyanobiphenyl in Example 1 were changed to 95.0 g of 4-chlorobenzonitrile and 6.5 g of 4-cyanobiphenyl. The first step of 1 and the second step are performed in the same manner to obtain a fine diketopyrrolopyrrole pigment composition.

[0324] The obtained fine diketopyrrolopyrrole pigment composition was observed by TEM as spherical particles with a primary particle size of 20 to 40 nm in diameter. The yield was 77.1g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com