Composite photonic structure element, surface emitting laser using the composite photonic structure element, wavelength conversion element, and laser processing device using the wavelength conversion element

A wavelength conversion and component technology, applied in instruments, optics, nano-optics, etc., can solve problems such as disordered position and orientation relationship, difficult beam orientation or polarization plane control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0120] First, a first embodiment of the present invention will be described. Hereinafter, in order to understand the present invention, it will be described in order starting with an easy-to-understand model.

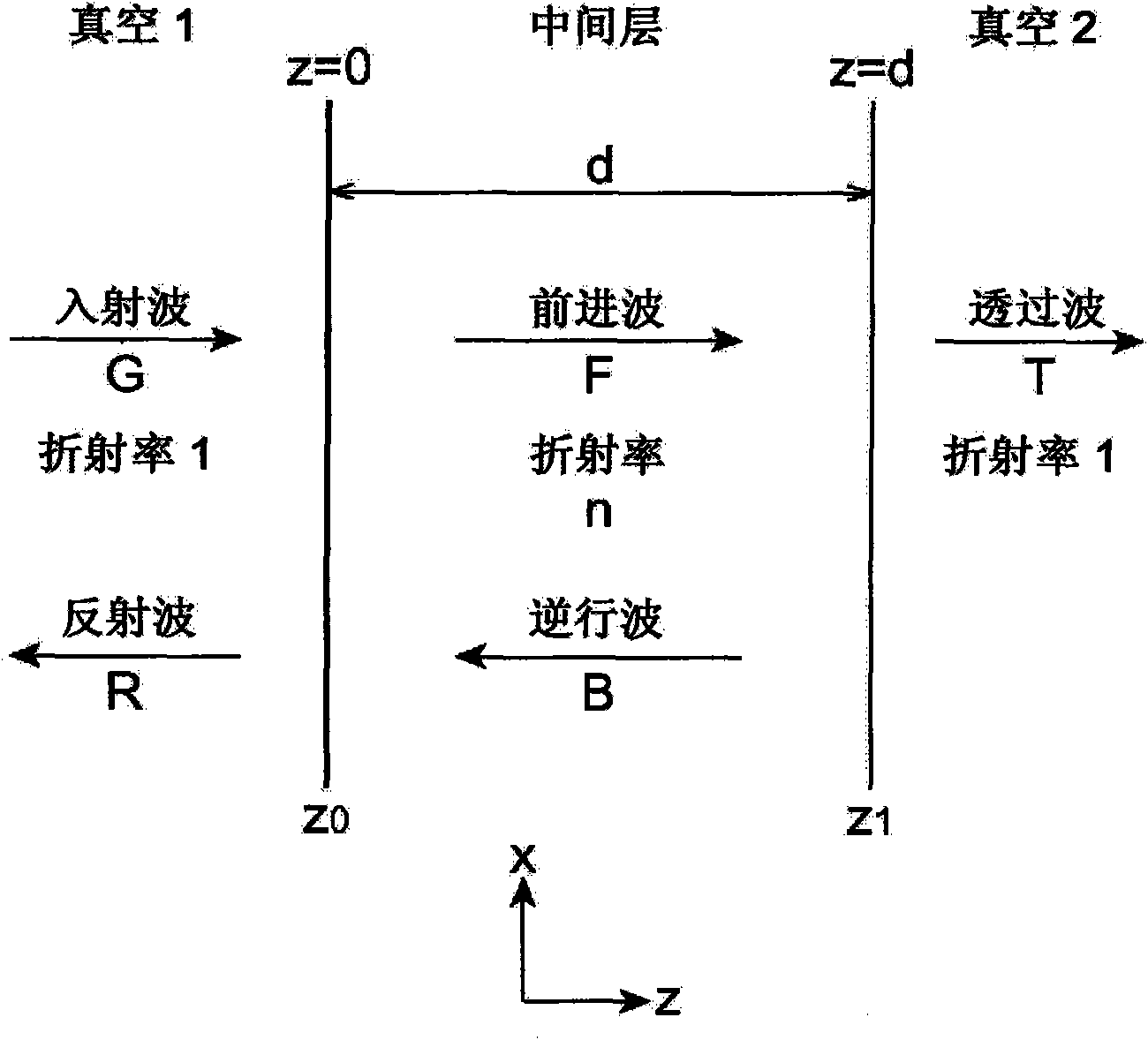

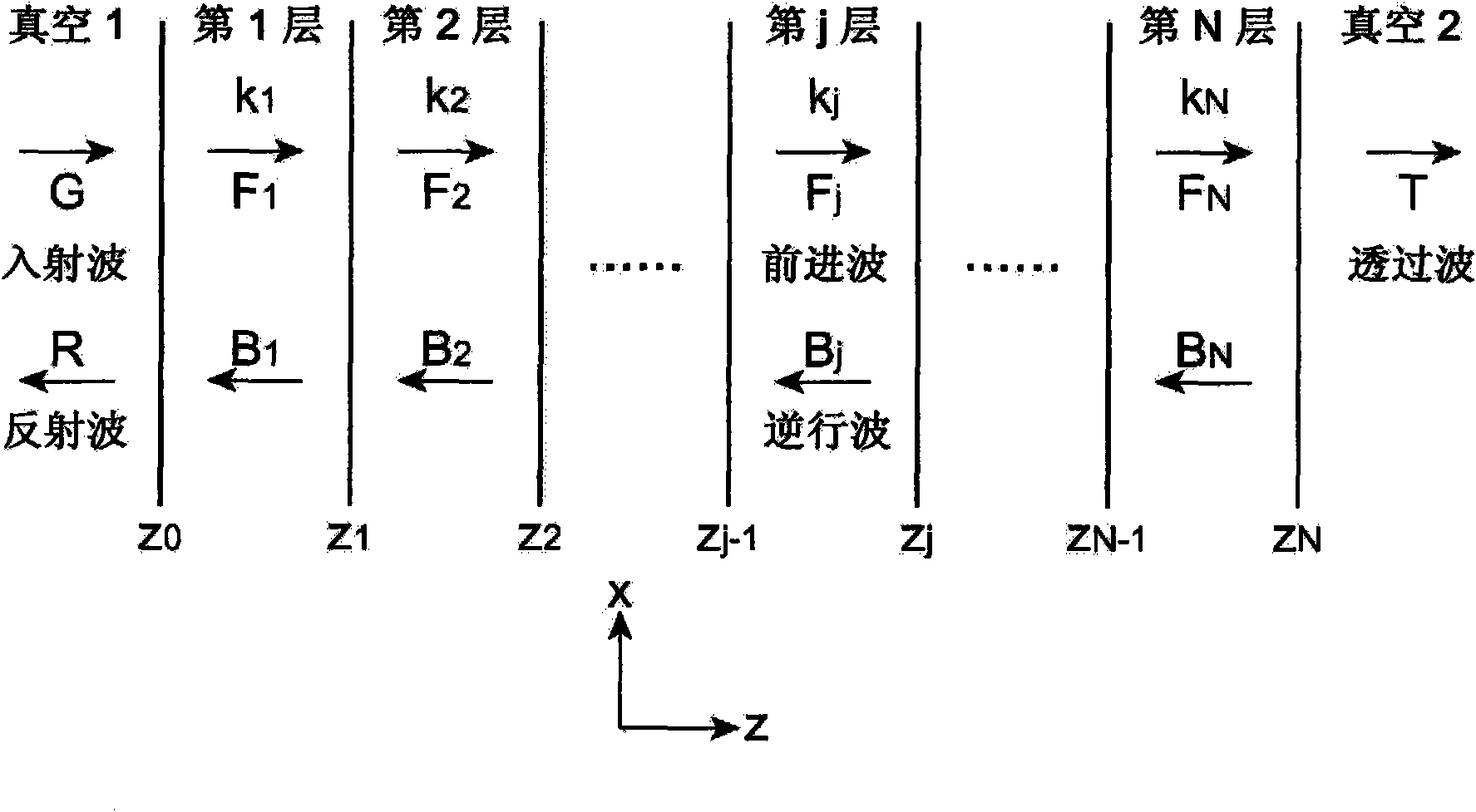

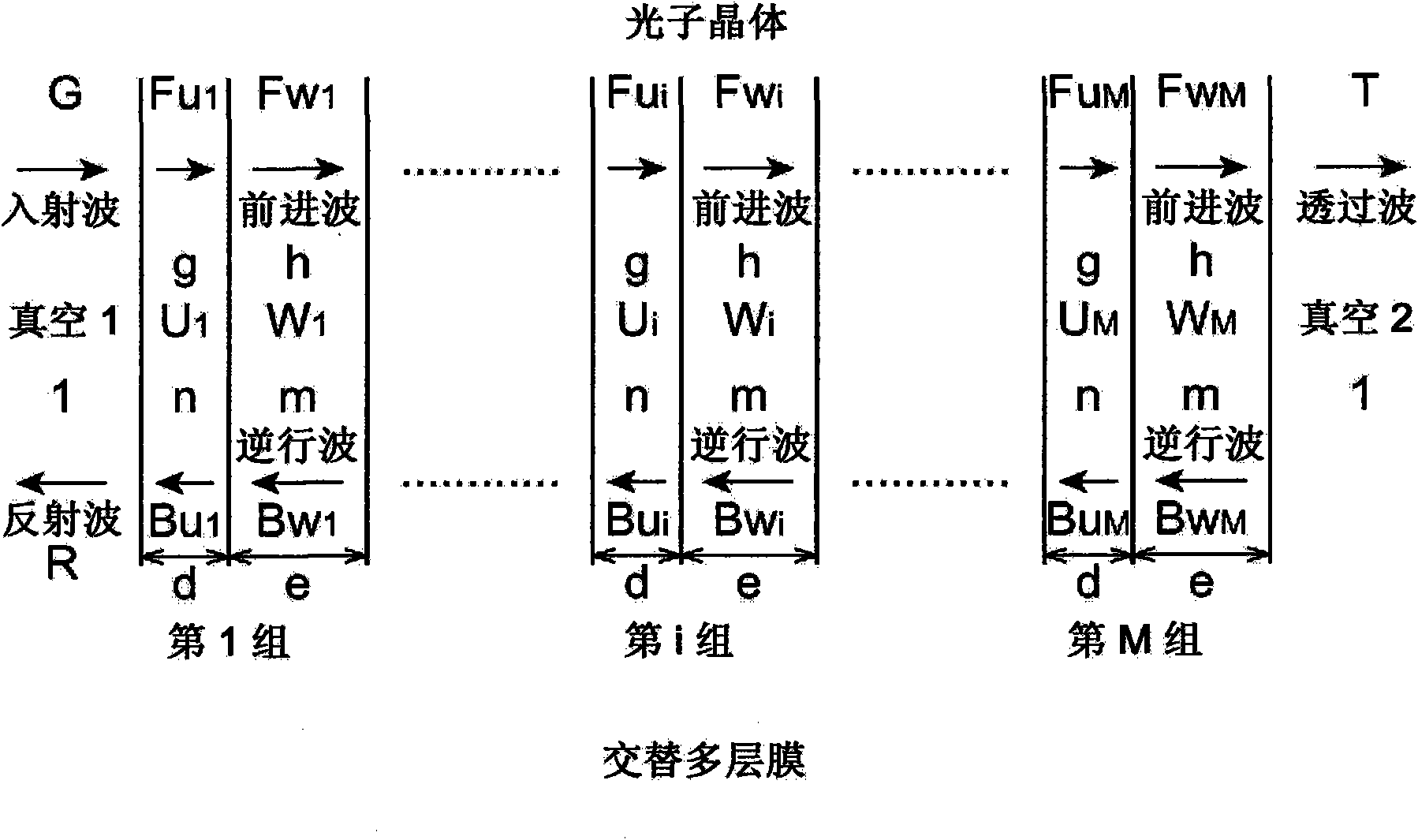

[0121] [1. Electric field of monolayer film]

[0122] First, the relationship of the steady-state electric field generated in the case of a monolayer film was investigated. Such as figure 1 As shown, it is formed in the form of vacuum 1, intermediate layer, and vacuum 2. Let the traveling direction of light be the z-axis, the upward coordinate be the x-axis, and the vertically upward coordinate with respect to the paper surface be the y-axis. Although oblique incidence is possible, here, for simplicity, the layers are arranged in the z direction so that the interface between the layers is the xy plane. Due to the use of plane waves, the electric field only has the x component E x . Since there is no distortion, only E exists in all layers x . Since it is the sam...

Embodiment 1

[0284] Next, Example 1 of the first embodiment of the present invention will be described.

[0285] If the embodiment of the present invention is explained from the beginning, it is difficult to fully understand its effect. Therefore, the case of a single-layer film and the case of a photonic crystal will be described in advance, and then the composite photonic crystal of the photon + resonator of the present invention will be described. Subsequently, a comparative example using a resonator sandwiched on both sides of a GaAs monolayer film will be described.

[0286] [1. In case of GaAs monolayer film ( Figure 4 )]

[0287] Figure 4 It shows the change in the intensity of the second harmonic when the film thickness L of the GaAs single-layer film is changed. The horizontal axis represents the film thickness L (nm). The vertical axis is the intensity of the second harmonic. The fundamental wave is infrared light with a wavelength of 1864 nm (161 THz) having energy of 0....

Embodiment 2

[0342] Next, Example 2 of the first embodiment of the present invention will be described.

[0343] [Embodiment 2: Changes in the second harmonic when the total number of layers is increased ( Figure 15 )]

[0344] On both sides of the GaAs / AlGaAs basic photonic crystal composed of 40 periods, a photonic crystal or resonator (reflector) of the same combination is further added, and the fundamental wave is vertically incident from one end, and the second harmonic generated on the opposite side is investigated. increase and decrease.

[0345] [1. Basic photonic crystal (GaAs / AlGaAs)]

[0346] The active layer is GaAs, the inactive layer is Al 0.79 Ga 0.21 As. The number of layers is 40 layers, forming 40 cycles.

[0347] Al 0.79 Ga 0.21 As dielectric constant 0.9×(light energy)+8.3

[0348] GaAs film thickness = 140nm,

[0349] Al 0.79 Ga 0.21 As film thickness = 147.5nm

[0350] 40 period film thickness = 11500nm

[0351] The intensity of the second harmonic is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com