Method for producing powder mixture for powder metallurgy, and method for producing sintered body

A manufacturing method and powder mixing technology, which is applied in transportation and packaging, metal processing equipment, etc., can solve the problems of powder segregation, internal defects, rough surface of sintered body, etc., and achieve the effect of low demoulding force and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0087] (Preparation of amide lubricant solution)

[0088] Add 4 parts of N-oleyl palmitamide (manufactured by Nippon Seika Co., Ltd.) as an amide lubricant to 20 parts of toluene as a solvent, and mix while heating to about 60°C to prepare an amide lubricant solution .

[0089] (Preparation of mixed powder for powder metallurgy)

[0090] The obtained amide-based lubricant solution was added to 100 parts of pure iron powder (manufactured by Kobe Steel Works, Ltd., 300M, particle size 50-150μm) as an iron-based powder and mixed, and then separately added as mechanical property improving powder 2.0 parts of copper powder (MAKIN METAL POWDERS, AHF-100, particle size 30-50 μm) and 0.8 parts of graphite powder (Japan Graphite Industry Co., Ltd., JCPBK, particle size 3-5 μm) are mixed, and then the toluene is distilled off under reduced pressure, A mixed powder for powder metallurgy was obtained (the addition amount of the amide-based lubricant to 100 parts of the total amount of t...

experiment example 2、3

[0096] (Preparation of amide-based lubricant solution, preparation of mixed powder for powder metallurgy, compression molding)

[0097] Add the amide-based lubricant solution so that the amount of the amide-based lubricant added is 0.4 parts (experimental example 2) or 0.5 part (experimental example 3) relative to the total amount of 100 parts of the iron-based powder and the mechanical property-improving powder, otherwise The outside is the same as in Experimental Example 1, and compressed powders 2-1 and 2-2 (above are Example 2), and compressed powders 3-1 and 3-2 (above is Experimental Example 3) were obtained.

[0098] (Characteristics of compressed powder)

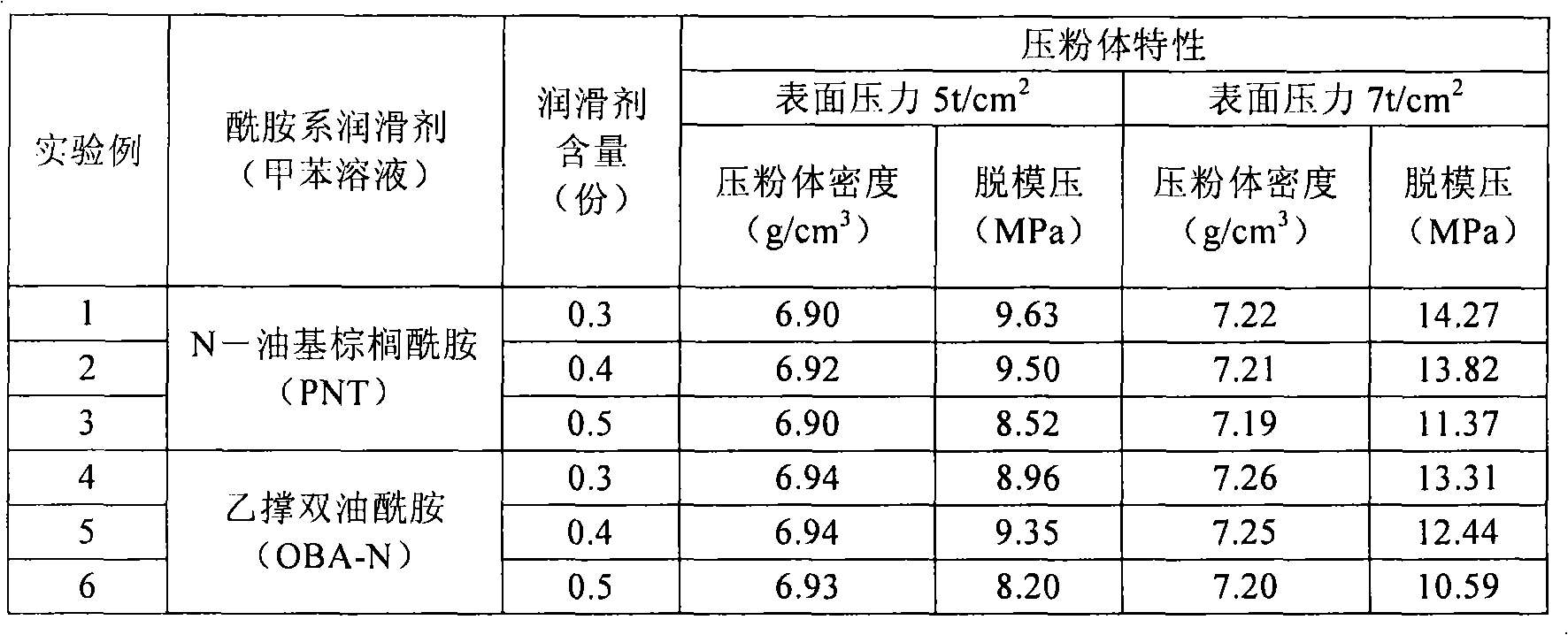

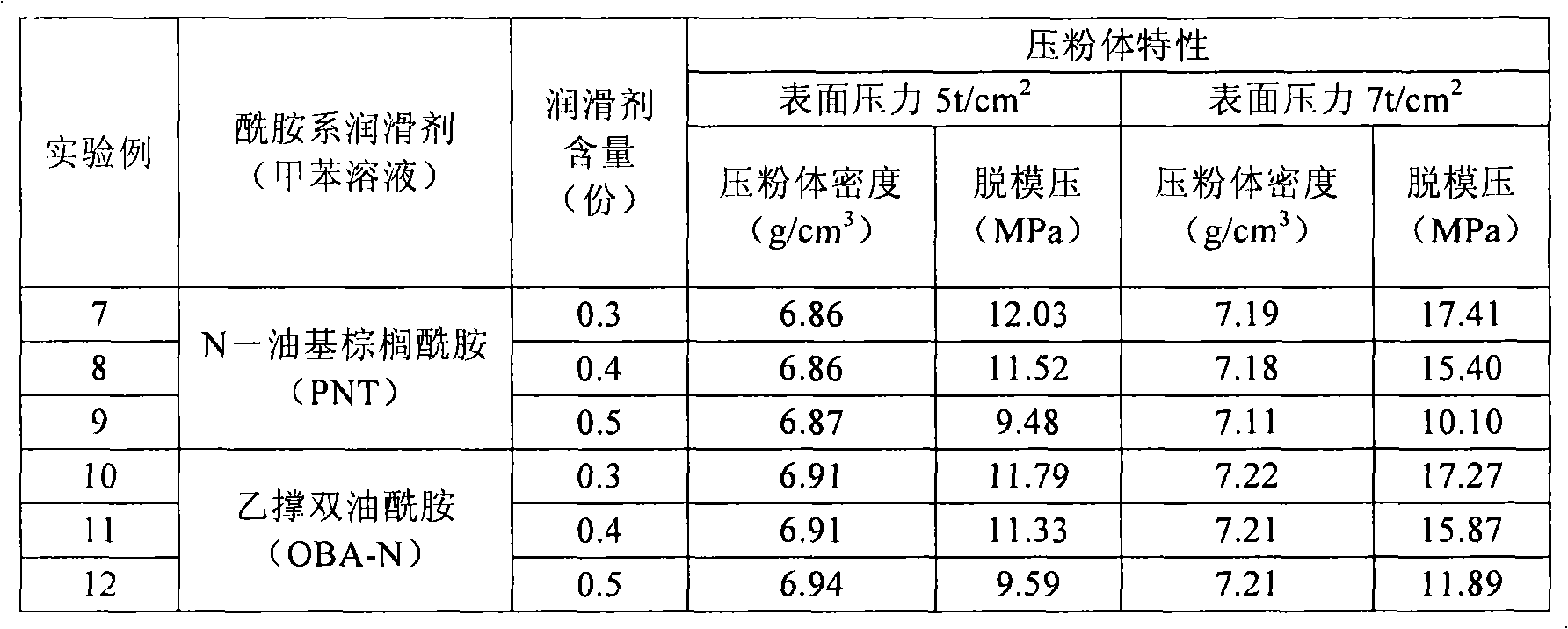

[0099] The densities of the obtained green compacts 2-1 and 2-2 and the green compacts 3-1 and 3-2, and the demolding pressure when they were released from the metal mold were measured, respectively. The results are shown in Table 1.

experiment example 4

[0101] (Preparation of amide-based lubricant solution, preparation of mixed powder for powder metallurgy, compression molding)

[0102] As the amide-based lubricant, ethylene bisoleamide was used instead of the N-oleyl palmitamide (manufactured by Dainippon Chemical Industry Co., Ltd.) used in Experimental Example 1, except that it was the same as in Experiment 1, and the pressure was obtained. Powder 4-1, 4-2.

[0103] (Characteristics of compressed powder)

[0104] The densities of the obtained green compacts 4-1 and 4-2, and the release pressures at the time of release from the mold were measured, respectively. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com