Method for producing decafluorobiphenyl

A technology of decafluorobiphenyl and pentafluorobenzoic acid is applied in the field of preparation of decafluorobiphenyl, can solve the problems of low yield, high cost of raw materials, unworkable industrialization routes, etc., and achieves high yield, low production cost, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

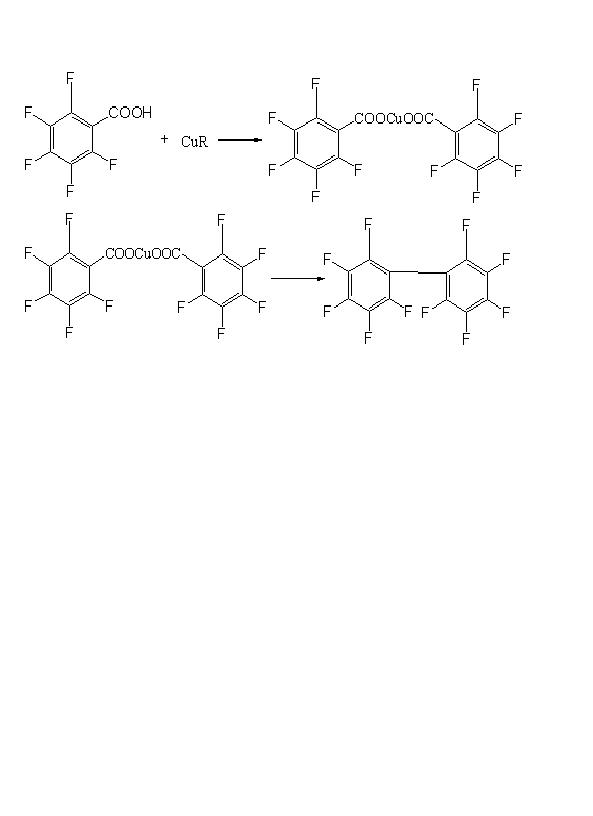

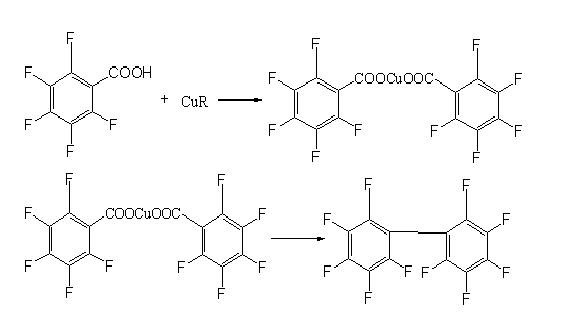

Image

Examples

Embodiment 1

[0019] Example 1: Weigh 50 g of pentafluorobenzoic acid, grind it, and put 12.6 g of catalyst copper oxide (molar ratio: pentafluorobenzoic acid:catalyst = 1.5:1), stir evenly, and put it into the reactor. Slowly start stirring, and slowly raise the temperature to 240°C, with an average of 0.8~1°C per minute. Obtained white solid: 37g, content 97%, calculated by pentafluorobenzoic acid, pure yield: 91.1%.

[0020] Take 50g of the product with a content of 97%, put it in a reactor, add (product: solvent weight ratio = 1:1) ethanol, heat up to 70 degrees to completely dissolve, cool to normal temperature, filter, and dry to obtain a solid: 45g, Sampling analysis content: 98.4%.

Embodiment 2

[0021] Example 2: The basic implementation steps are the same as the first paragraph of Example 1, except that the amount of catalyst copper oxide is changed to 21g (molar ratio: pentafluorobenzoic acid:catalyst=0.9:1), and the white solid is obtained: 37.5g, content 97.5%, based on pentafluorobenzoic acid, the pure yield is: 92.8%.

Embodiment 3

[0022] Example 3: The basic implementation steps are the same as the first paragraph of Example 1, except that the amount of catalyst copper oxide is changed to 10.5g (molar ratio: pentafluorobenzoic acid:catalyst=1.8:1), and a white solid is obtained: 32g, content 97%, based on pentafluorobenzoic acid, the pure yield is: 78.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com