Fuel oil composition

A composition and fuel oil technology, applied in fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve problems such as poor control of viscosity and density, low utilization rate of heat energy, insufficient combustion, etc., and achieve considerable economic benefits and products The effect of cost reduction and good calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Take 10 parts of petroleum by-product heavy residue, whose viscosity at 100°C is 1800mm 2 / s; 50 parts of low temperature coal tar, its density is 920kg / m 3 , its viscosity at 50°C is 5mm 2 / s; 30 parts of shale oil, viscosity 20mm at 50°C 2 / s; 10 parts of diesel oil, with a flash point of 68°C; put it into a blending tank at 55-65°C and fully stir for 10-14 hours, and filter out impurities to obtain 4# fuel oil.

example 2

[0024] Take 40 parts of petroleum by-product heavy residue, whose viscosity at 100°C is 620mm 2 / s; 5 parts of low temperature coal tar, its density is 1035kg / m 3 , its viscosity at 50°C is 35mm 2 / s; 53 parts of shale oil, its viscosity at 50°C is 9.5mm 2 / s; 2 parts of diesel oil, with a flash point of 55°C; put it into a blending tank at 55-65°C and fully stir for 10-14 hours, and filter out impurities to obtain 180# fuel oil.

example 3

[0026] Take 60 parts of petroleum by-product heavy residue, whose viscosity at 100°C is 500mm 2 / s; 27 parts of low temperature coal tar, its density is 1005kg / m 3 , its viscosity at 50°C is 17mm 2 / s; 5 parts of shale oil, its viscosity at 50°C is 5mm 2 / s; 8 parts of washing oil with a flash point of 80°C, put it into the mixing tank at 55°C to 65°C and fully stir for 10 to 14 hours, filter out impurities to obtain 380# fuel oil.

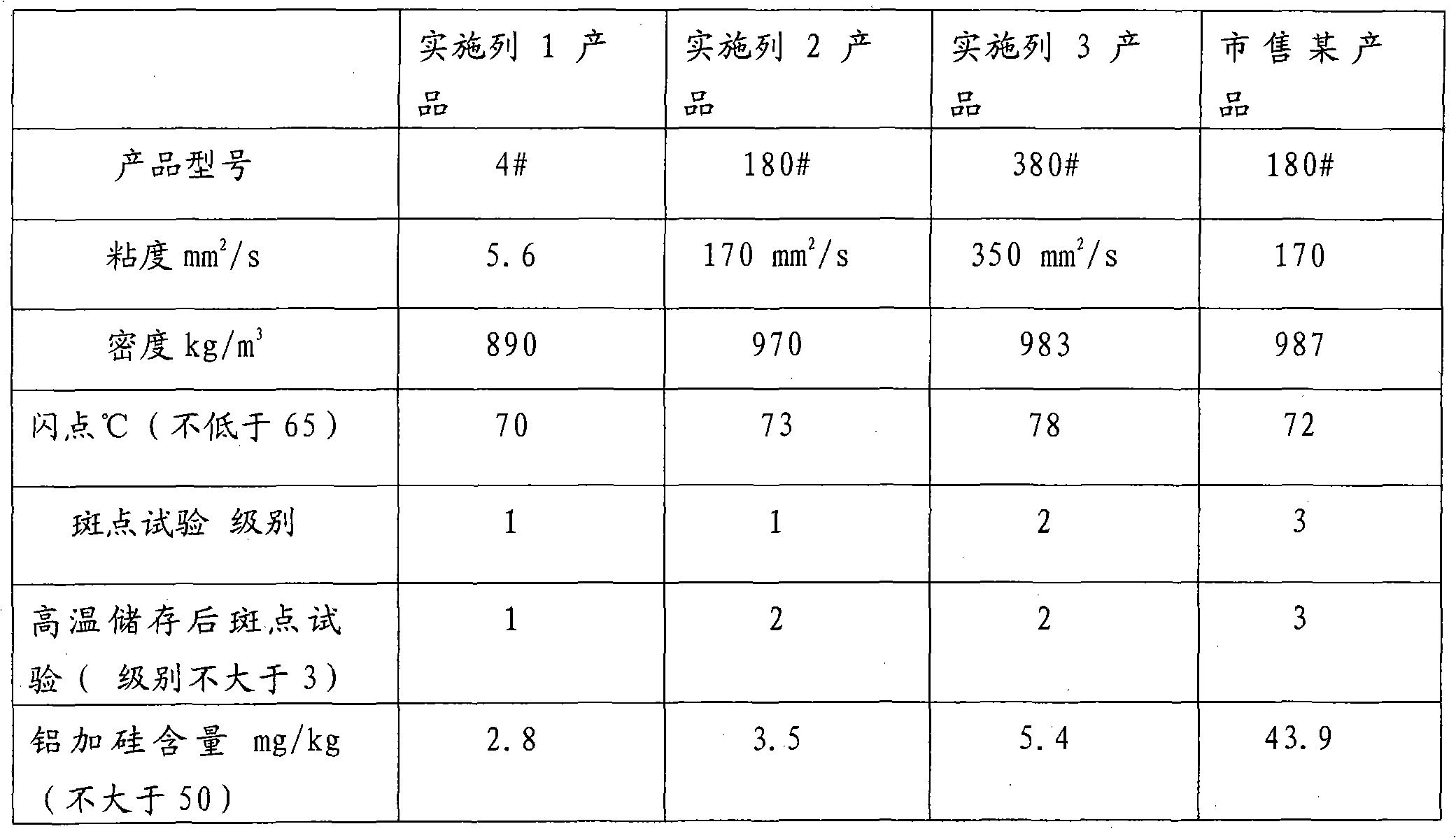

[0027] The indicators of each series of products and a similar product on the market are as follows:

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com