New dyeing method of active dye taking methylsiloxane as medium

A technology of methyl siloxane and reactive dyes, applied in dyeing, textile and papermaking, etc., can solve the problems of toxicity safety, high equipment requirements, serious equipment pollution, etc., to enhance the reaction ability, improve the adsorption rate, improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

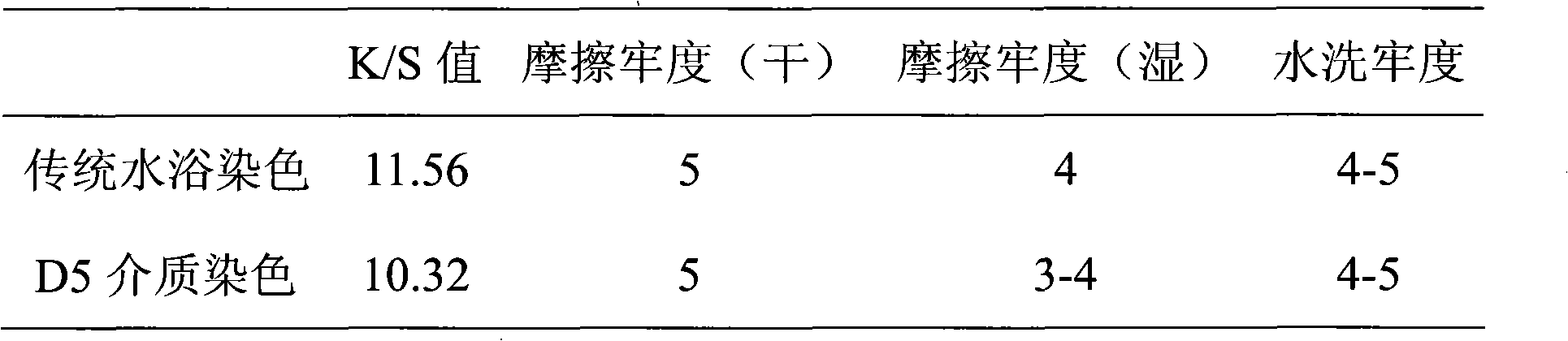

Embodiment 1

[0028] 1. Fabric dyeing pretreatment

[0029] 1g pure cotton fabric with 60g / L Na 2 CO 3 After fully swollen, carry out one-dip and one-roll treatment, control the liquid-carrying rate of about 150%, and wait for dyeing;

[0030] 2. Preparation of reactive dye dispersion system

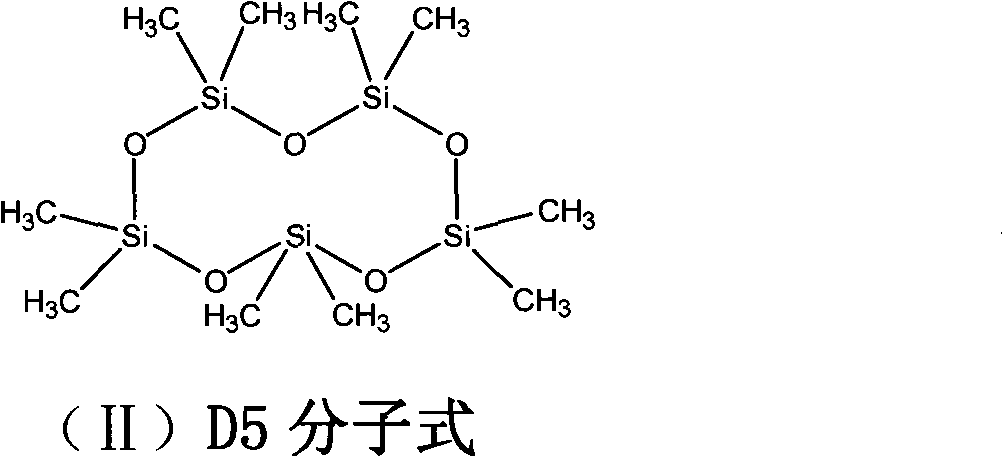

[0031] Add 0.02g reactive red M3-BS to 10ml D5 (molecular structure as shown in II) and 0.1g oleic acid, put it in a ball mill and mill it for 2-3h to complete the surface modification and prepare a stable dye dispersion system for use ;

[0032]

[0033] Take a certain amount of the above-mentioned modified reactive dyes and add them to the medium 20mlD5 and stir evenly, control the amount of pure dyes to be 2% of the weight of the fabric to be dyed according to the dyeing concentration requirements, and control the amount of dyeing medium so that the weight of the fabric to be dyed and the total amount of the medium The ratio (bath ratio) is 1:5, fully stirred, the dye is uniformly dispersed ...

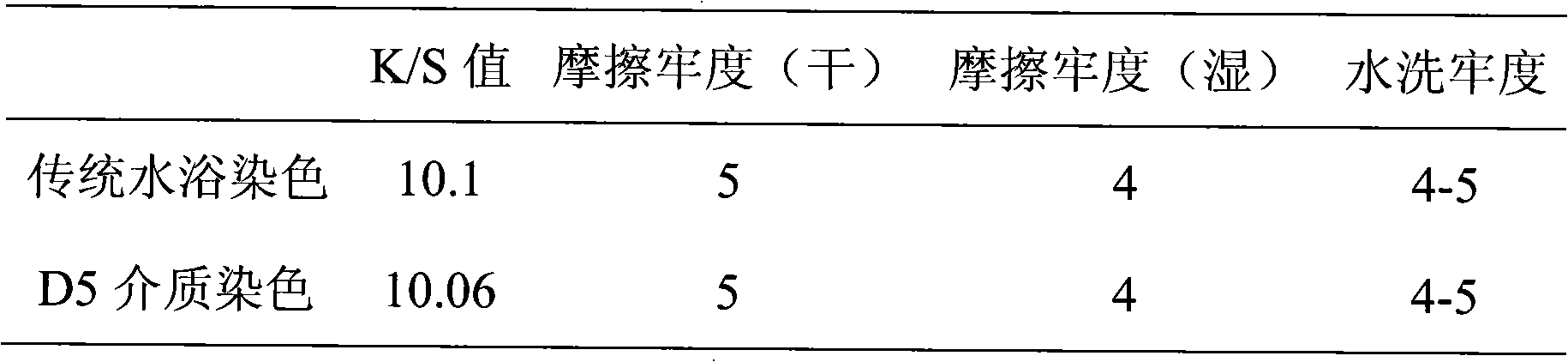

Embodiment 2

[0039] 1. Fabric dyeing pretreatment

[0040] 1g pure cotton fabric with 60g / L Na 2 CO 3 After fully swollen, carry out one-dip and one-roll treatment, control the liquid-carrying rate of about 150%, and wait for dyeing;

[0041] 2. Preparation of reactive dye dispersion system

[0042] Add 0.02g of reactive yellow M3-RE to 10ml of D5 and 0.1g of oleic acid, put it in a ball mill and mill it for 2-3 hours to complete the surface modification and prepare a stable dye dispersion system for use;

[0043] 3. Preparation of dye bath

[0044] Take a certain amount of the above-mentioned modified reactive dyes and add them to the medium 20mlD5 and stir evenly, control the amount of pure dyes to be 10% of the weight of the fabric to be dyed according to the dyeing concentration requirements, and control the amount of dyeing medium so that the weight of the fabric to be dyed and the total amount of the medium The ratio (bath ratio) is 1:20, fully stirred, the dye is uniformly dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com