Method and device for producing casein and whey protein by separating milk

A technology for whey protein and casein, which is applied in the field of producing casein and whey protein, and achieves the effects of convenient cleaning, easy control and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following embodiments are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

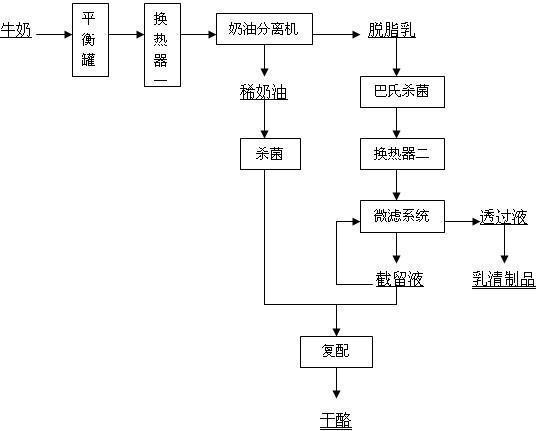

[0024] Fresh milk (the total number of bacteria <200,000 / ml) is pre-filtered in the balance tank, and then the temperature is raised to 55°C through the heat exchanger, and the cream is centrifuged with a cream separator, and the obtained skim milk is heated to 72°C and kept warm. Pasteurize after 15s, then cool down to 50°C through heat exchanger 2, and enter the ceramic membrane microfiltration system with a pore size of 0.14 μm, with a flow rate of 5 m / s and a transmembrane pressure of 0.5 Bar. According to the specific requirements of calcium content of different cheese varieties, different concentration factors are selected, the retentate is enriched with casein, and the permeate is enriched with whey protein.

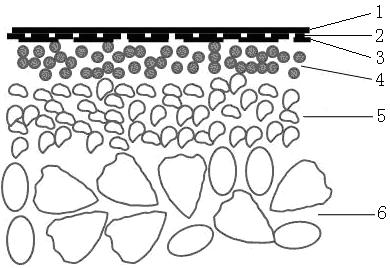

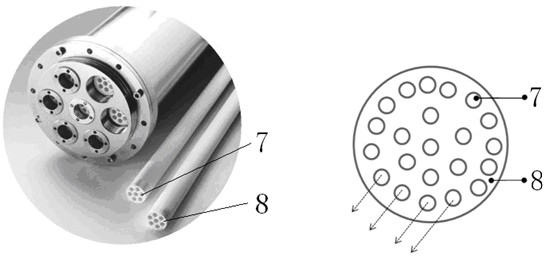

[0025] The working process of the ceramic membrane microfiltration system is as follows: the skim milk separated by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com