Manufacturing process of parts related to elbow and wrist joint of artificial upper limb

A manufacturing method and wrist joint technology, applied in the field of prosthetics, can solve the problems of cumbersome processing methods, low production efficiency, single material selection, etc., and achieve the effects of light weight, improved production efficiency, and simplified production process

Inactive Publication Date: 2010-12-29

李秀胜

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to overcome the disadvantages of single material selection, cumbersome and complicated processing methods, and low production efficiency in the traditional process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiment:

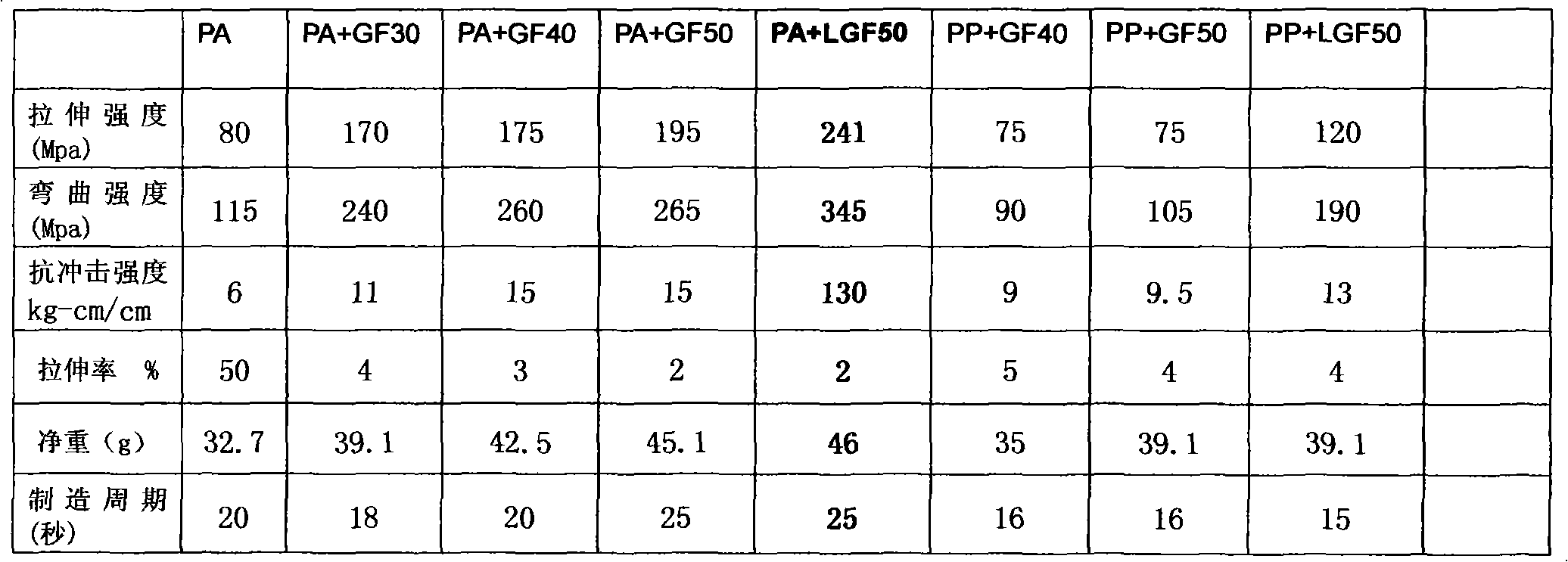

[0022] The following table selects different material values for each embodiment:

[0023]

[0024] In the above table, GF means glass fiber content (unit: %), and LGF means long glass fiber content (unit: %).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a manufacturing process of the parts related to the elbow and wrist joint of an artificial upper limb. The manufacturing method is that a novel composite material with mixed nylon and long glass fiber is used to perform the injection molding process instead of the traditional metal cutting machining process. The related parameters of the selected material and the related technological parameters are as follows: 1. the composite material with mixed nylon and long glass fiber comprises the following components by weight percent: 30%-50% of nylon (PA), 50%-65% of glass fiber, 2-3% of coupling agent, 1-2% of plasticizer and 1% of other components; 2. the injection process of the composite material is that the temperature of the material tube is 280-310 DEG C, the injection pressure is 40Mpa, the injection time is 15-35 seconds and the shaped parts are completely cooled at the room temperature; and 3. the parts are dried at 130 DEG C for 4-6 hours before shaped. An injection machine with the tonnage of 100-500 is used to inject the fused liquid raw material in the injection moulds through an injection machine, and the novel composite material is adopted to prepare the parts related to the elbow and wrist joint of the artificial upper limb through the process technology of injection molding.

Description

technical field [0001] The invention relates to a manufacturing method of a prosthesis, in particular to a manufacturing method for upper limb elbow joints and wrist joints, using new composite materials through an injection molding process. Background technique [0002] At present, the production process of the relevant parts of the upper limb prosthetic joint is metal cutting machine forming. The processes used involve wire cutting, turning, milling machine processing, grinding machine processing, and CNC machine tool processing. There are many production processes, heavy workload, and long labor hours. , To form large-scale production, the required equipment, personnel, and time investment are relatively large, the production cost is high, and the production efficiency is low. [0003] The injection molding process of the new composite material is to bake the new composite material of nylon mixed with long glass fiber to the temperature and humidity suitable for injection...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29C45/00C08L77/00C08K7/14B29C45/76B29B13/06

Inventor 李秀胜

Owner 李秀胜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com