High-temperature resistant metal sealing material for mixed conductor oxygen permeable ceramic membrane and application method thereof

A mixed conductor and metal sealing technology, which is applied to the high temperature resistant metal sealing material for mixed conductor oxygen-permeable ceramic membrane and its application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

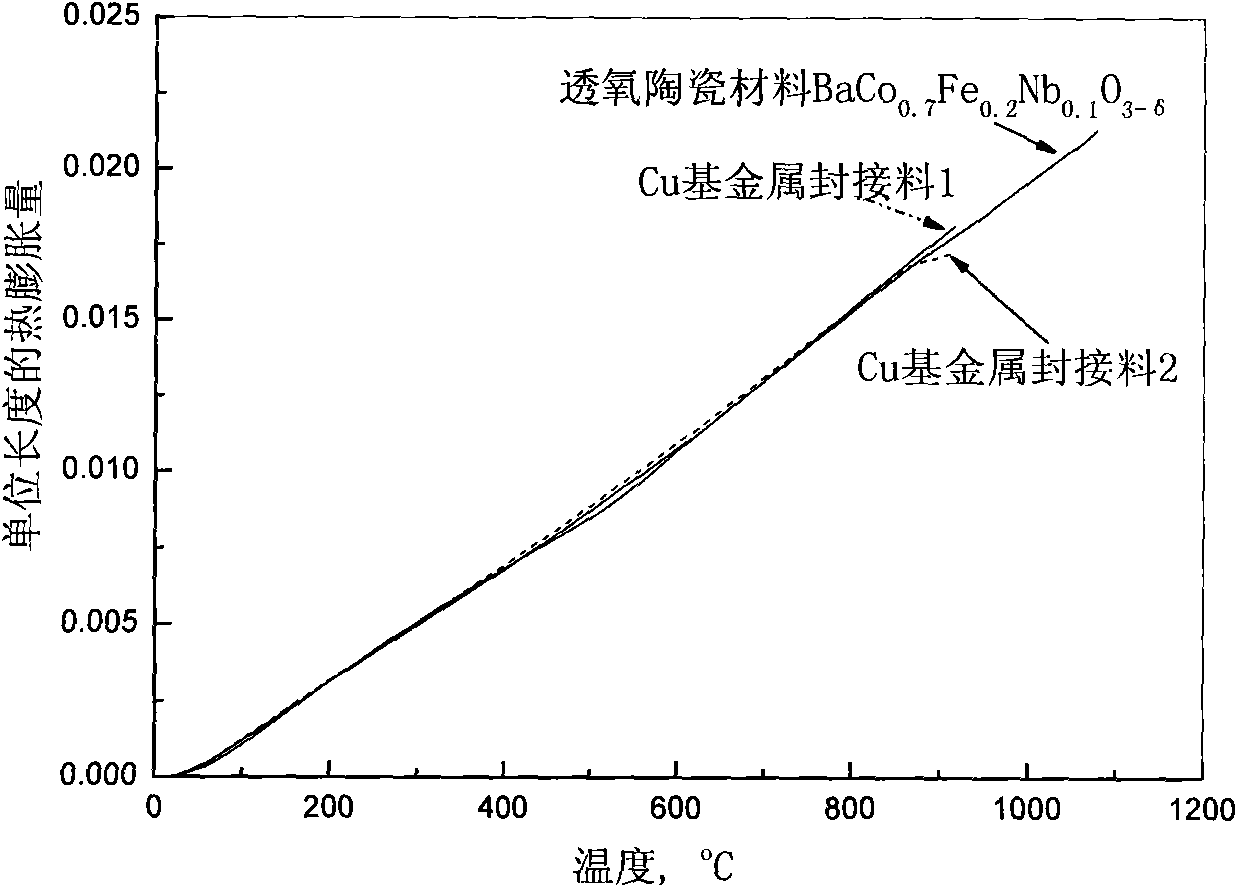

[0028] The metal sealing material of the present invention is Cu-based metal solder in the embodiments, and the composition of the Cu-based metal solder in Embodiment 1 to Embodiment 4 is shown in Table 1 below.

[0029] Table 1 Composition list of Cu-based metal solder (weight percent)

[0030] composition

Cu

sn

Al

Zn

Fe

Pb

Ni

P

Example 1

92.648

6.5

0.002

0.3

0.05

0.2

0.2

0.1

Example 2

93.14

6.0

0

0.3

0.01

0.05

0.2

0.3

Example 3

94.2

5

0

0.2

0.03

0.04

0.3

0.2

Example 4

92.199

7

0.001

0.1

0

0.1

0.1

0.5

[0031] The preparation method of metal sealing material, i.e. Cu-based metal solder, is as follows:

[0032] According to the weight percentage of each component of each embodiment listed in Table 1, a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com