Book defect automatic detection method and detection device

An automatic detection device and automatic detection technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high labor intensity, high missed detection and false detection rate, slow inspection speed, etc. The effect of high detection accuracy and increased work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

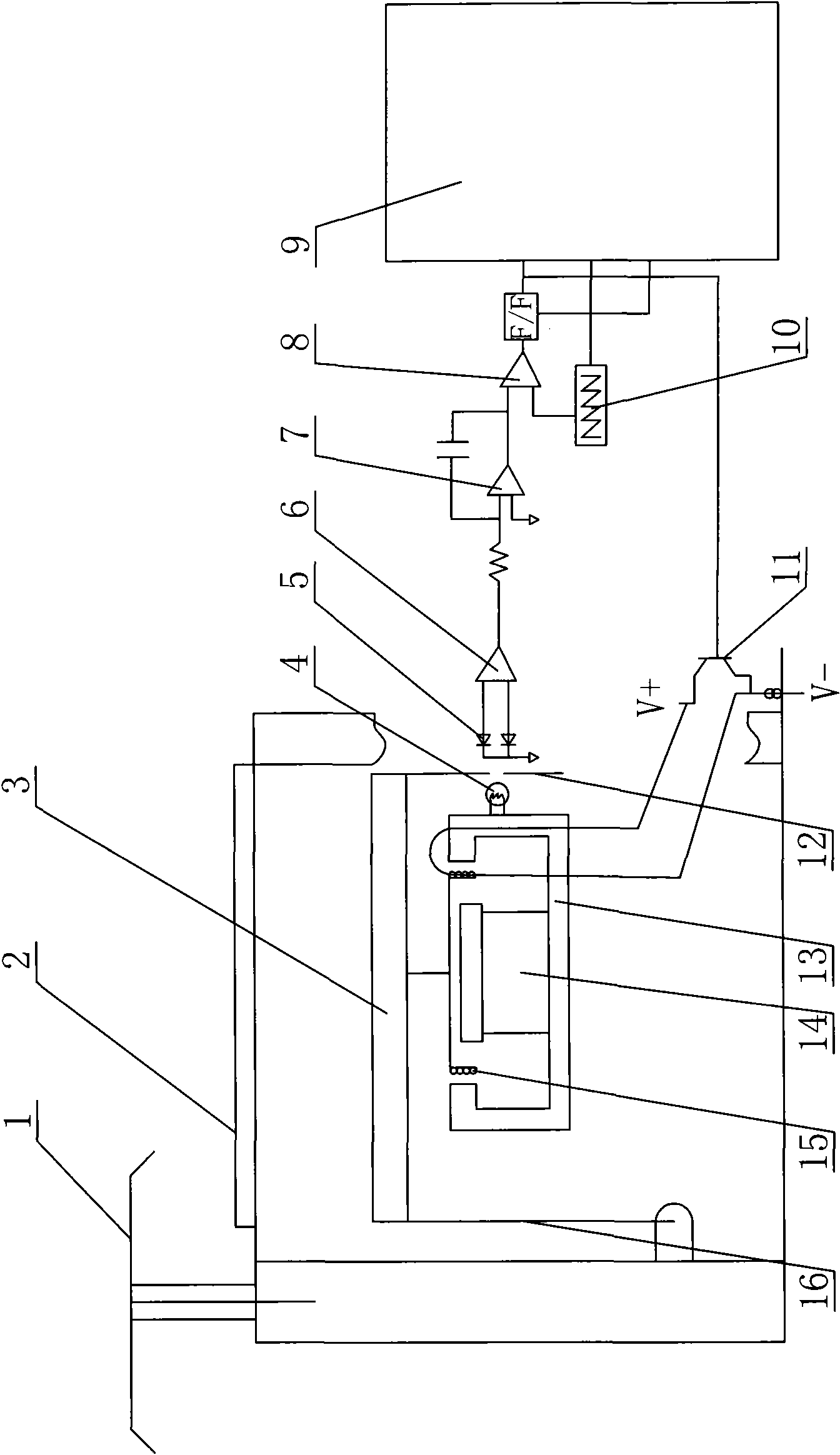

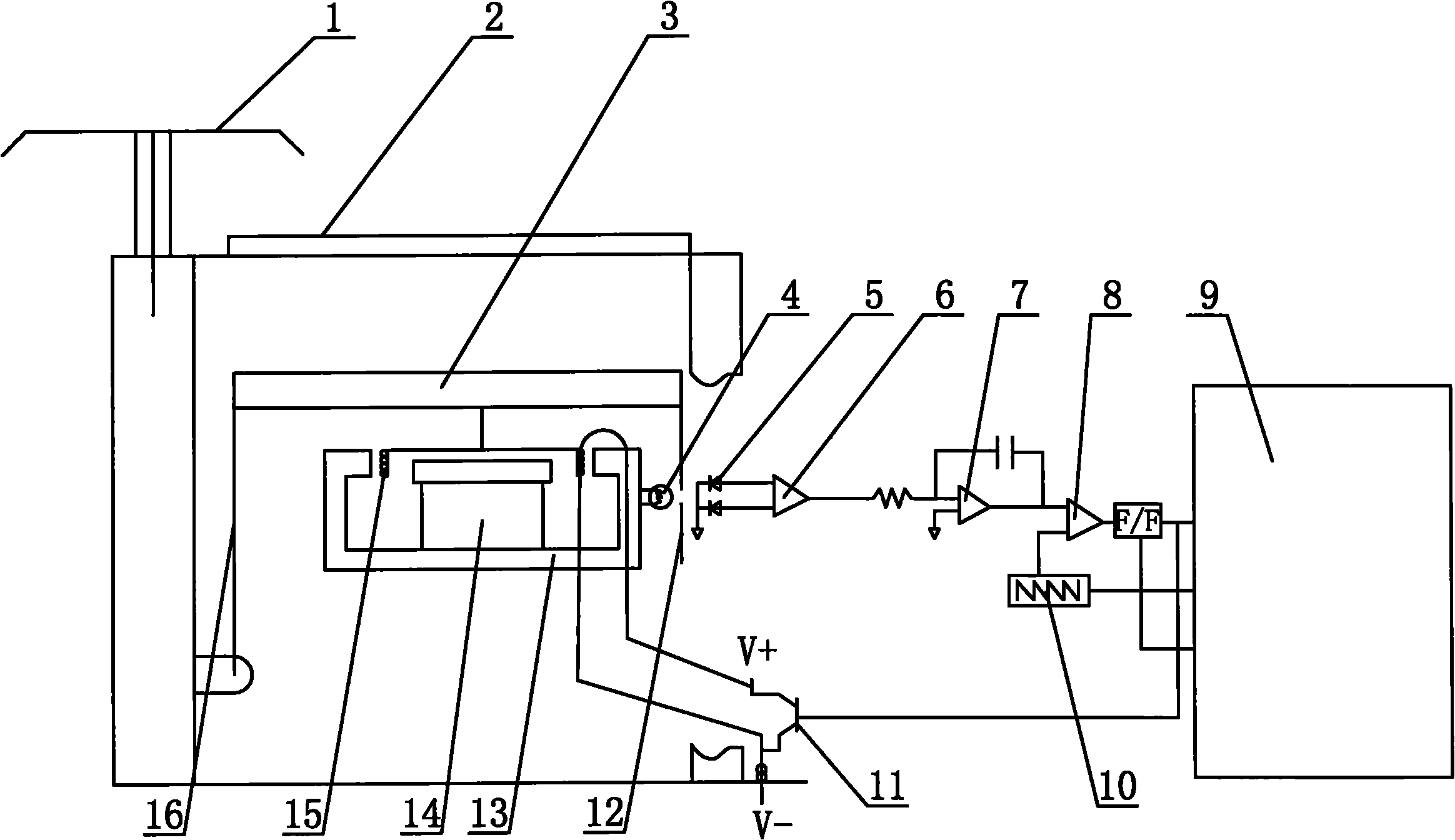

[0018] The weighing part is mainly composed of a weighing tray 1, a beam 3 connected to the weighing tray 1 by an elastic connecting piece 16, a magnet 14 below the beam 3, a force coil 15 on the periphery of the magnet 14, and a coil frame 13. The light-emitting diode 4 of the sensor part is fixed on the outside of the bobbin 13, and corresponds to the photodiode 5 of the sensor part through the light barrier 12, and the photodiode 5 is connected to the A / D converter 6, the controller 7, the comparator 8, and the transistor switch 11. , the afterburner coil 15 and the light emitting diode 4 form a closed-loop servo system, and the output end of the comparator 8 is connected with the I / O interface of the computer system 9 . The transistor switch 11 is respectively connected to the output end of the comparator 8 and the force coil 15 to realize electromagnetic force feedback balance. The other end of the ramp generator 10 connected to the computer system 9 is connected to the i...

Embodiment 2

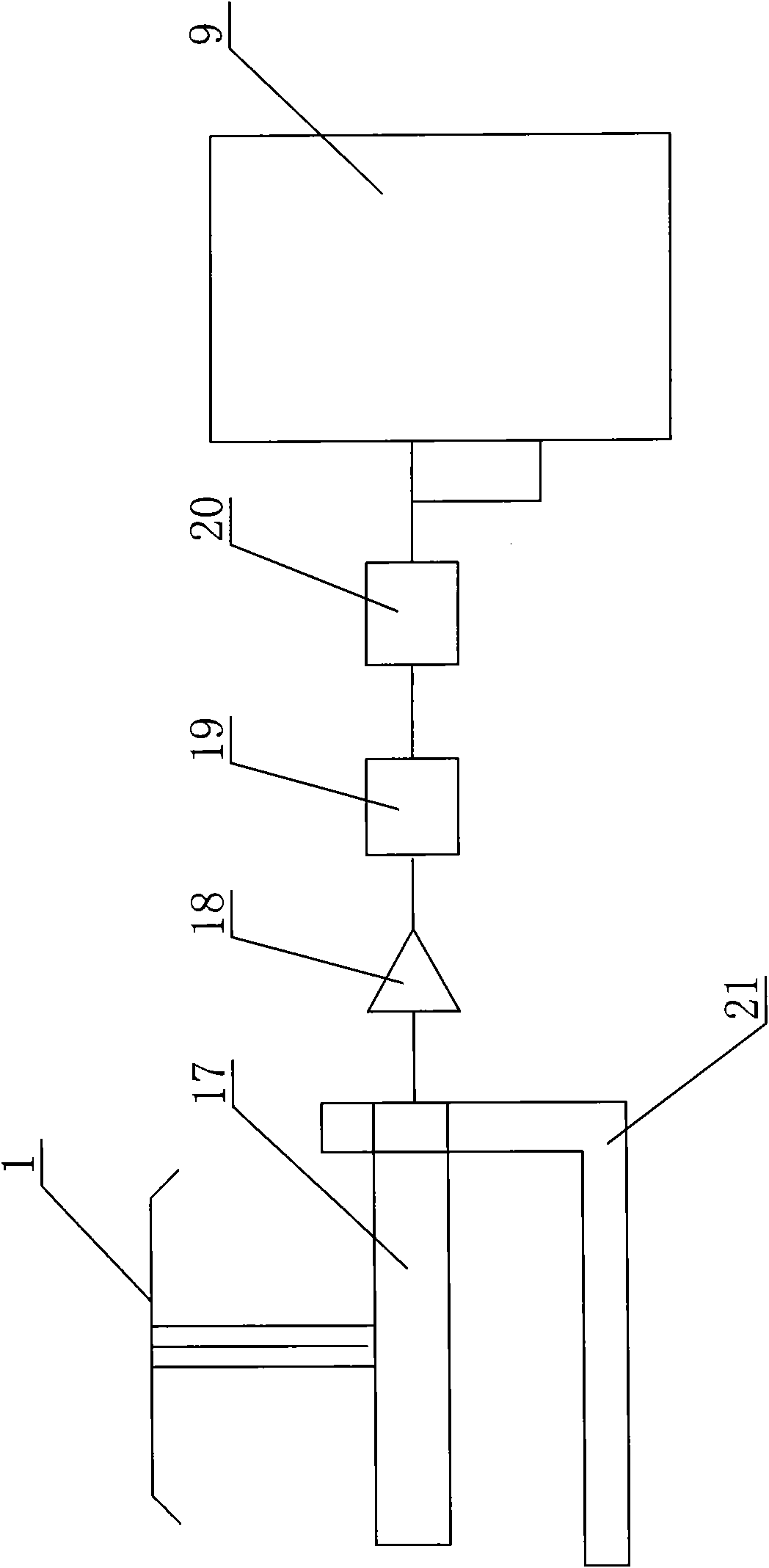

[0023] A strain gauge sensor 17 is arranged below the weighing tray 1 of the weighing part, and the strain gauge sensor 17 is fixed on the fixed bracket 21 at the same time, and the strain gauge sensor 17 is sequentially connected with the signal amplifier 18, the analog filter 19, and the A / D converter 20, The output end of the A / D converter 20 is connected with the I / O interface of the computer system 9 .

[0024] When the detected book is placed on the weighing tray 1, the sinking of the weighing tray causes the deformation of the strain sensor 17, thereby changing its resistance value, and then the measuring circuit converts this resistance change into an electrical signal, thereby completing the The external force is converted into an electrical signal, and finally converted into a digital signal by the A / D converter 20, and the computer system 9 I / O interface receives the signal and performs data processing.

[0025] There are two types of the above-mentioned A / D convers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com