Mining multi-wave self-adaptive active noise control system

An active noise control and self-adaptive technology, which is applied to self-adaptive and active control methods to reduce noise, adopts the multi-wave field, which can solve the problems that the noise signal cannot be eliminated in time, and the convergence speed performance is poor, so as to eliminate noise pollution, Increased relevance, ease of maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following implementation examples will further illustrate the present invention, and implementation examples should not be considered as limiting the scope of the present invention. The working mode of the present invention will be described in detail below in conjunction with the accompanying drawings.

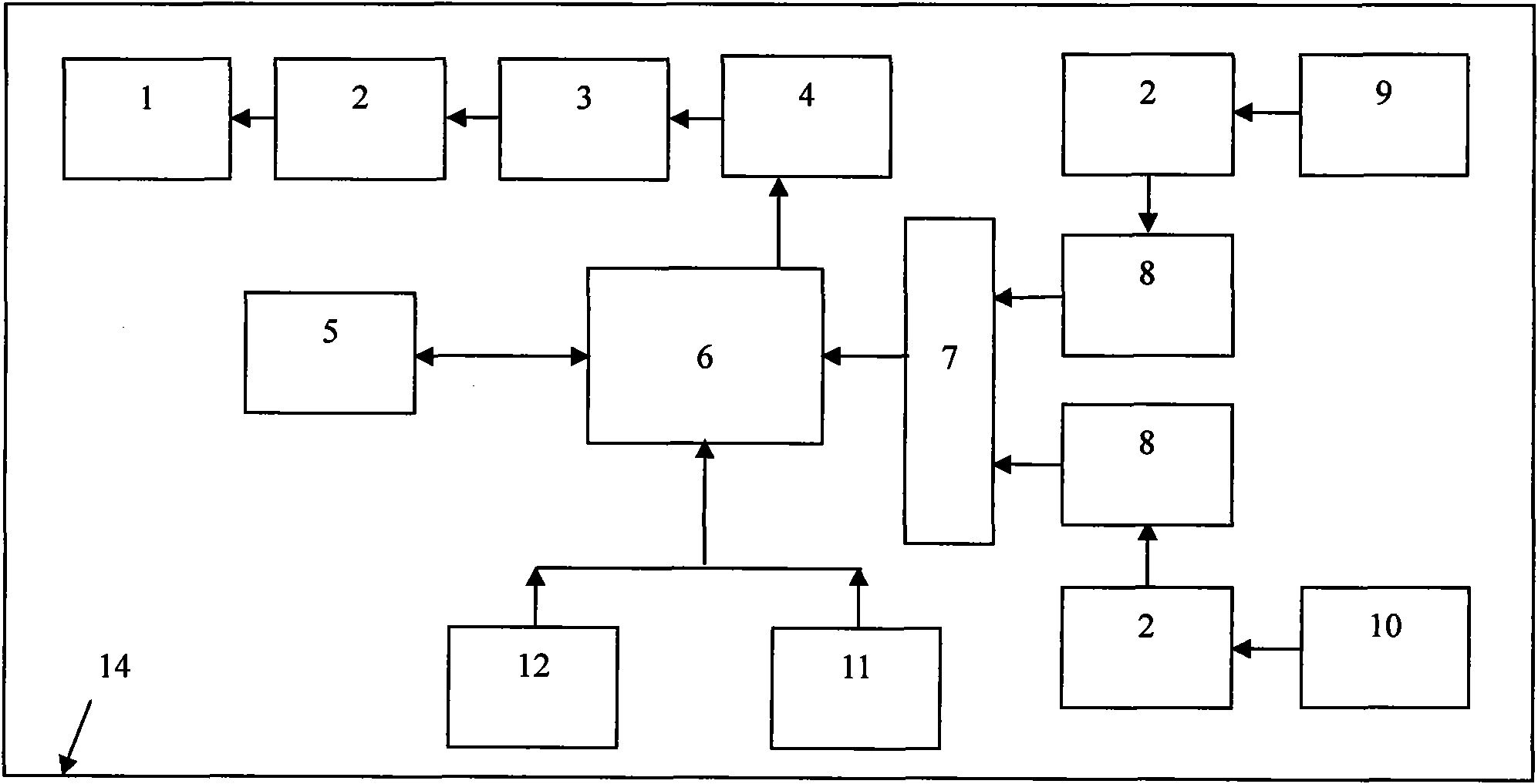

[0048] Such as figure 1 As shown, the mining multi-wave adaptive active noise control system of the present invention includes a primary sensor array 9, an error sensor array 10, a loudspeaker array 1, a power amplifier circuit module 2, a low-pass filter 3, and an A / D conversion module 8 , D / A conversion module 4, ANC controller 13, field programmable gate array (FPGA) 7, wireless transmission module 5, flameproof enclosure 14, backup battery circuit 11, main power supply circuit 12.

[0049] The system workflow is as follows:

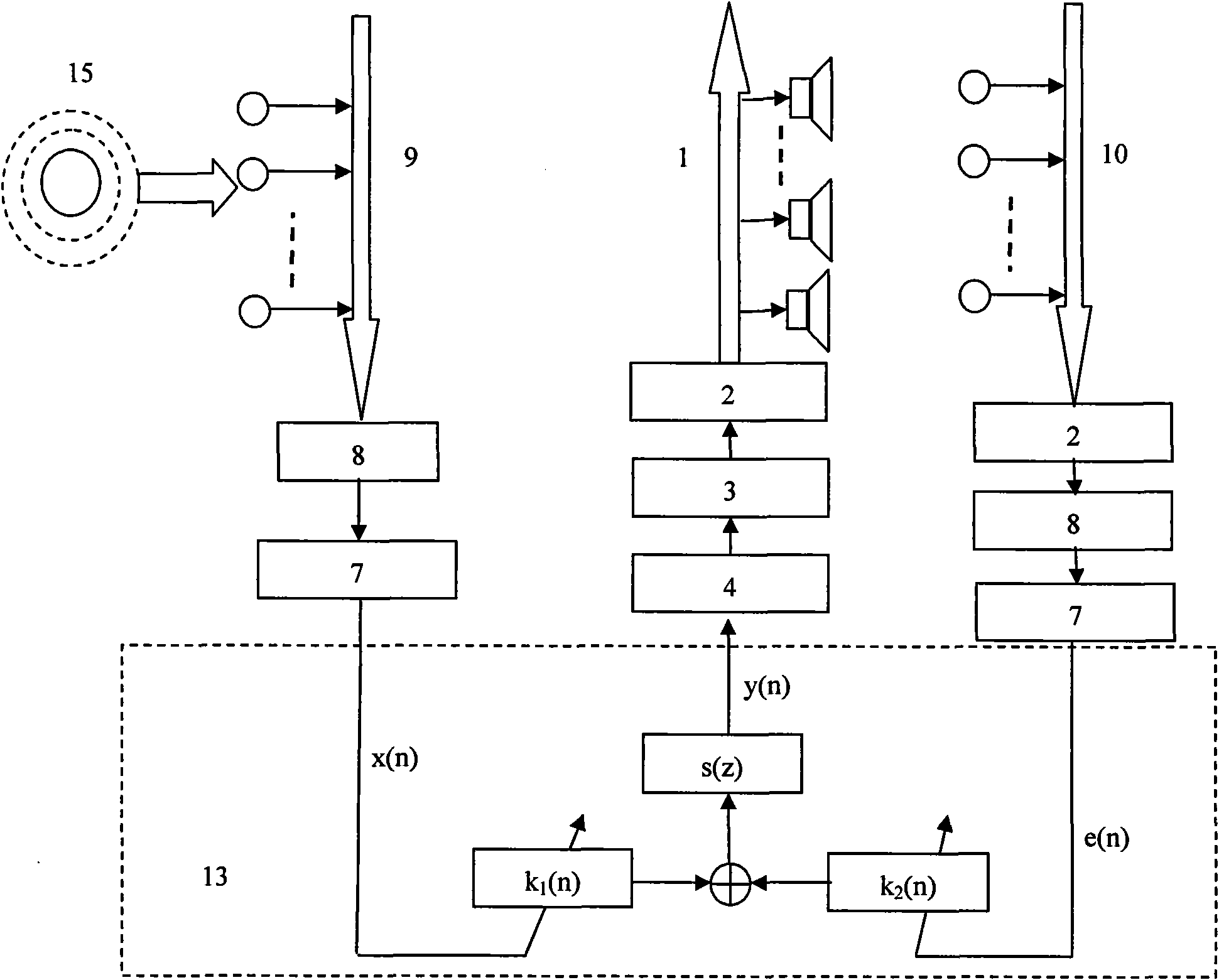

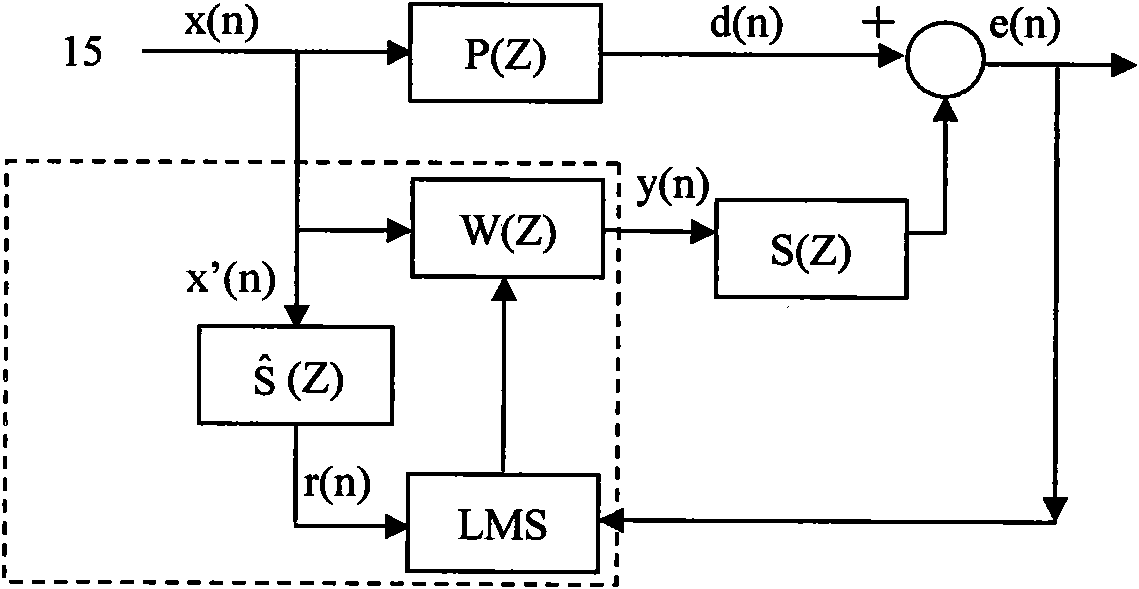

[0050] Such as figure 2 As shown, after the primary sensor array 9 detects the mine noise 15, it converts the sound signal into an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com