Forwardly and reversely symmetrical P-type radial varying doping and similar table-board negative angle shaped junction terminal thyristor

A forward and reverse, junction terminal technology, applied in the direction of thyristors, electrical components, circuits, etc., can solve the problems of asymmetric forward and reverse blocking voltages of thyristors, loss of cathode area, reduction of current capacity, and large occupied area of molding area. , to achieve the effect of high voltage sheet thickness ratio, reduced occupied area, and small loss of cathode surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

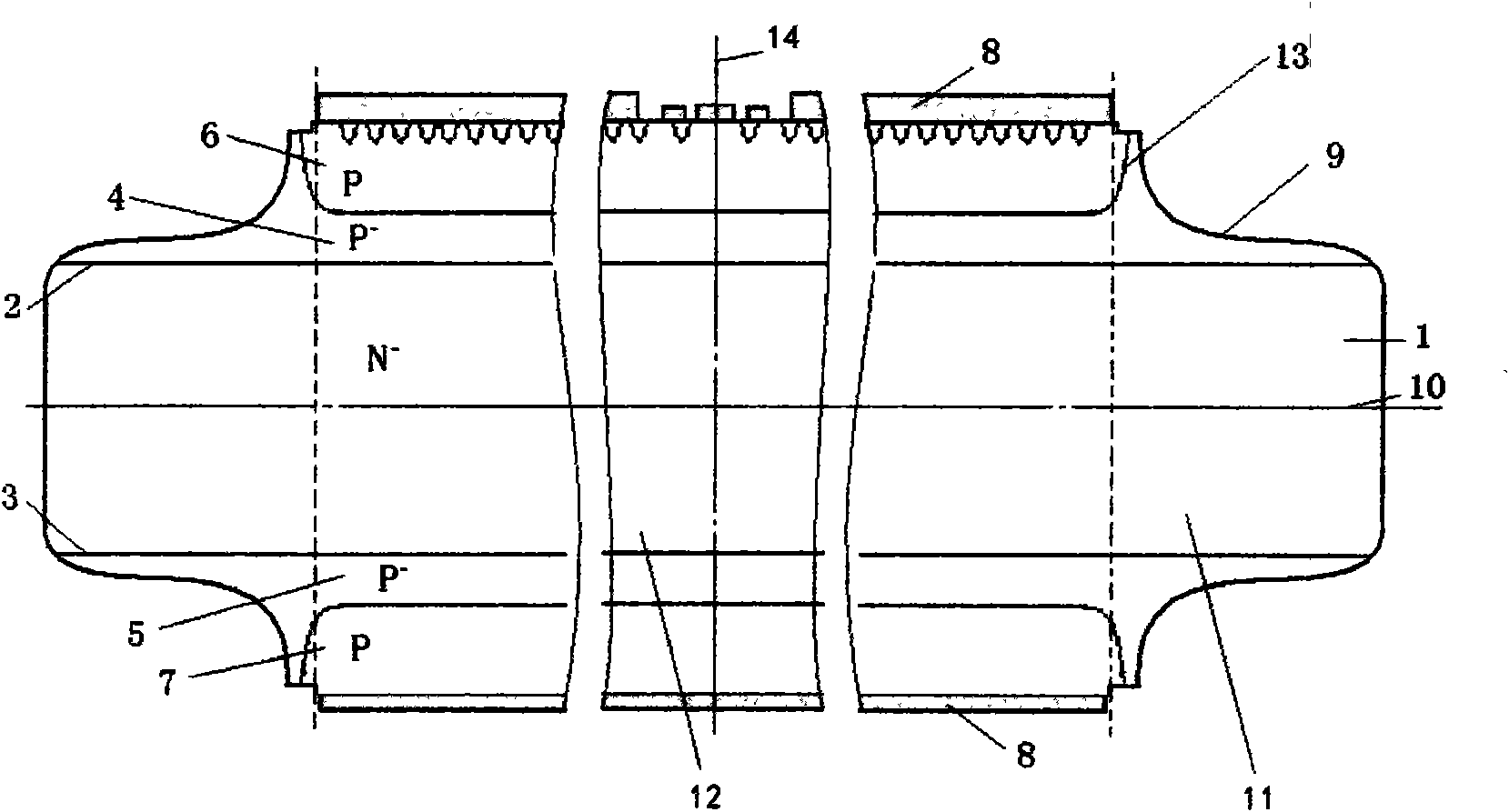

[0012] The present invention includes N - Type substrate (1), forward blocking junction (2), reverse blocking junction (3), forward and reverse blocking junctions (2, 3) are respectively provided with low concentration P - Type doped layers (4, 5) and higher concentration P-type doped layers (6, 7), which are divided into the general thyristor internal region (12) inside the metal ohmic contact layer (8) and the junction outside the metal ohmic contact layer (8). In the terminal region (11), the implementation mode of manufacturing positive and reverse symmetric P-type radial variable doping is: first, N - Type substrate (1) Two-sided symmetrical low-concentration P on both sides of the original single wafer - Type doping, the junction depth is 20-40μm shallower than the type II junction terminal structure, and the sheet resistance Rs is 500-1000Ω, forming a low-concentration P - Doped layer (4, s5), low concentration P - Type doped layer (4, 5) in N - The forward and reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com