Electric debugging method of dry-quenching power distribution system

A technology of power supply and distribution system and debugging method, which is applied in the direction of electrical components, circuit breaker testing, measurement of electricity, etc., can solve problems such as unreasonable, complicated and unscientific debugging process, and achieve high operation efficiency and simple debugging method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

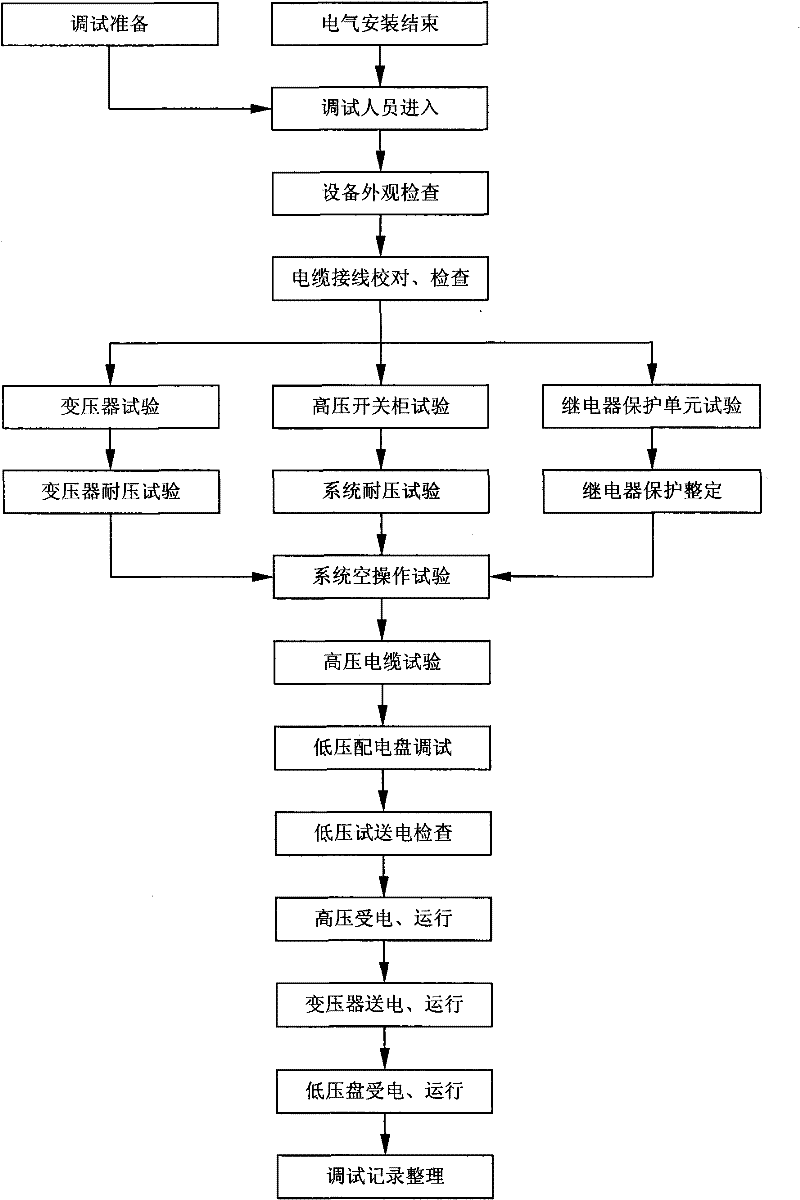

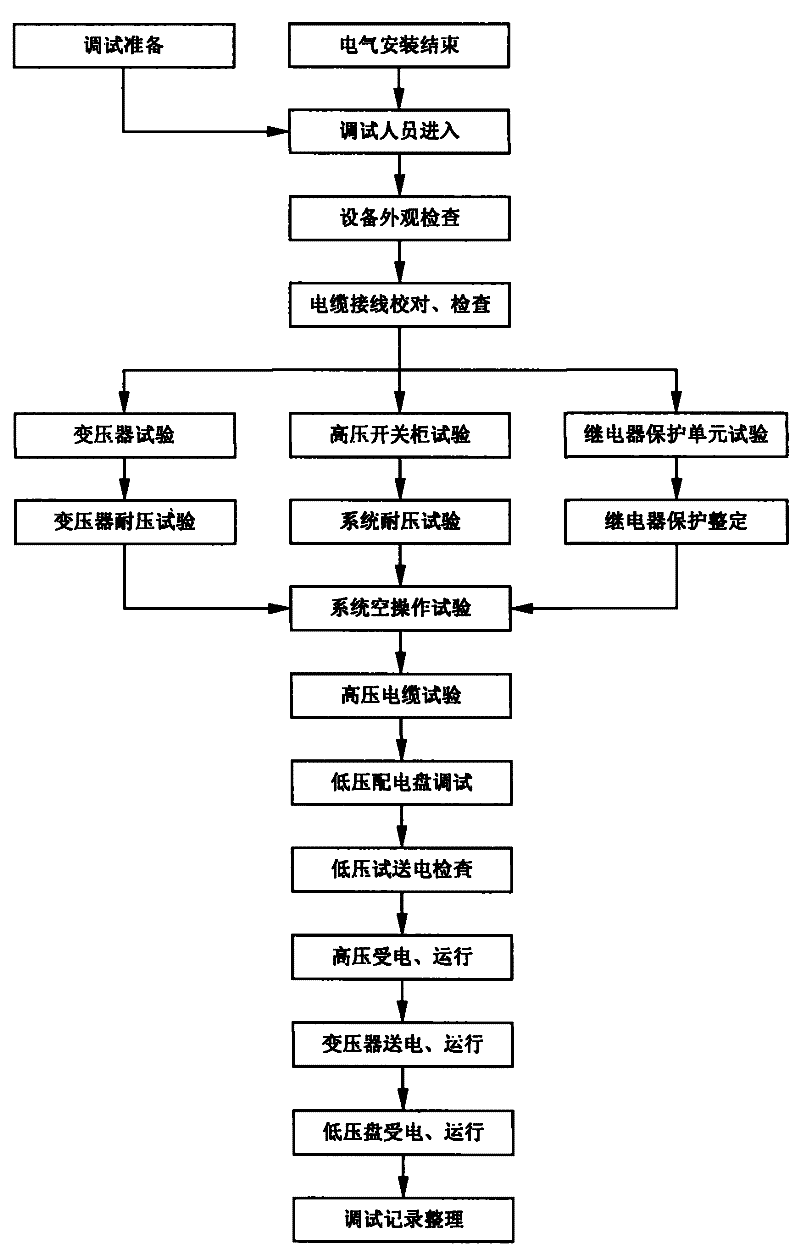

[0021] An electrical debugging method for CDQ power supply and distribution system, which is carried out after the electrical installation and debugging preparations are completed and the debugging personnel enter, and the following steps are carried out in sequence: a. Equipment appearance inspection, b. Cable wiring proofreading, inspection, c. Transformer test, d. High voltage switchgear test, e. Relay protection unit test, f. Transformer withstand voltage test, g. System withstand voltage test, h. Relay protection setting, i. System dry operation test, j. High voltage cable test, k. Debugging of low-voltage switchboards, l. Low-voltage trial power transmission inspection, m. High-voltage power reception, operation, n. Transformer power transmission, operation, o. Low-voltage panel power reception, operation and p.

[0022] Complete the following construction preparations before commissioning:

[0023] 1. Technical preparation

[0024] (1) Before commissioning, the project...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com