Filter assembly

A filter and component technology, applied in the field of filters, can solve the problems of large dielectric rods, difficult to handle, frequency tuning can only be performed in one direction, etc., to achieve the effect of multi-welding and waste cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The invention is limited to filter assemblies that may be practiced in the embodiments described in detail below.

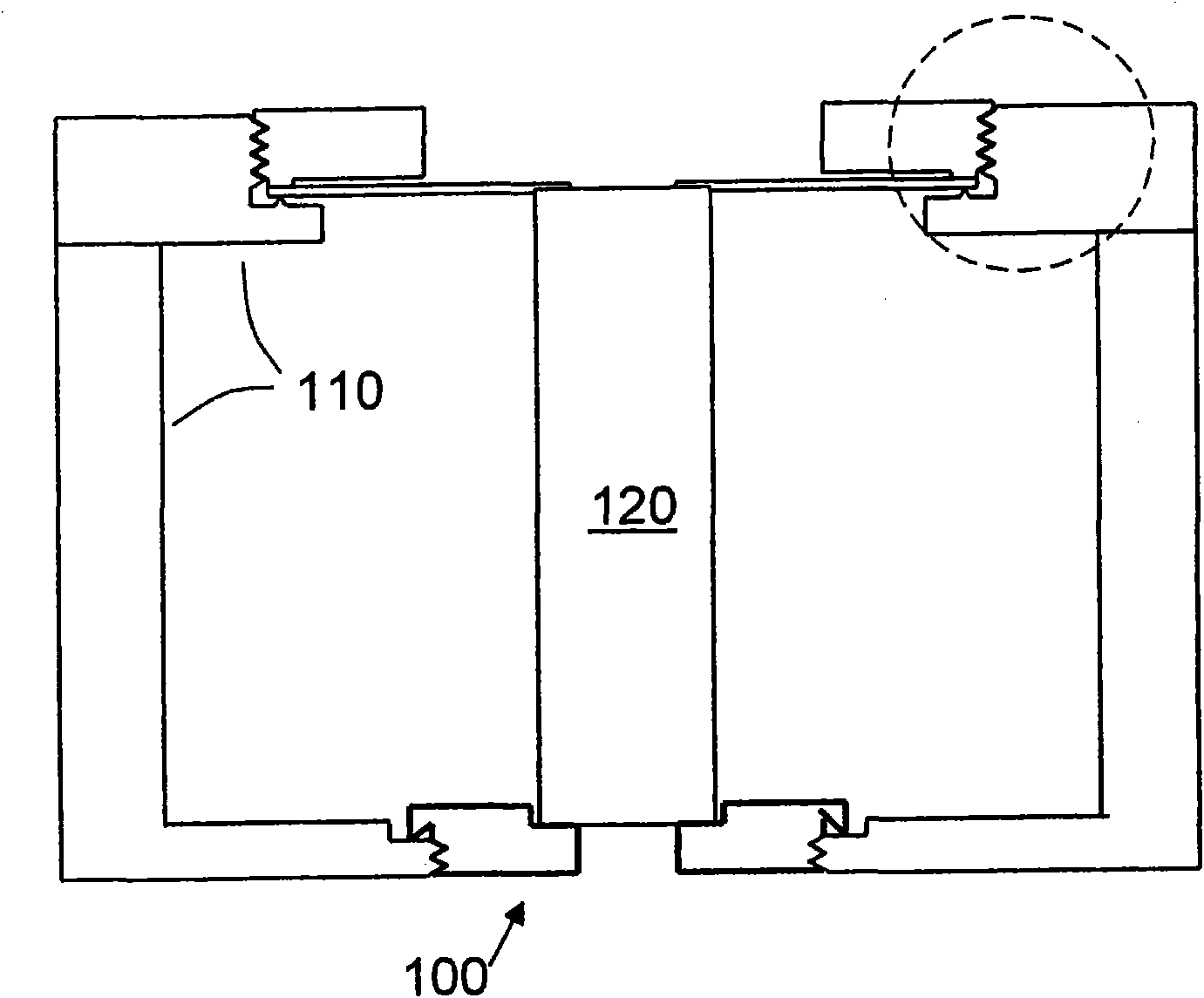

[0033] figure 1 A cross-section of a filter assembly 100 according to an embodiment of the invention is shown. The filter assembly 100 includes a filter base 110 and at least one dielectric rod 120 . The filter assembly 100 according to this solution may comprise a plurality of dielectric rods 120, for example thirty. then in figure 1 Only one dielectric rod 120 is depicted in . Filter assembly 100 may be a TM single mode resonator.

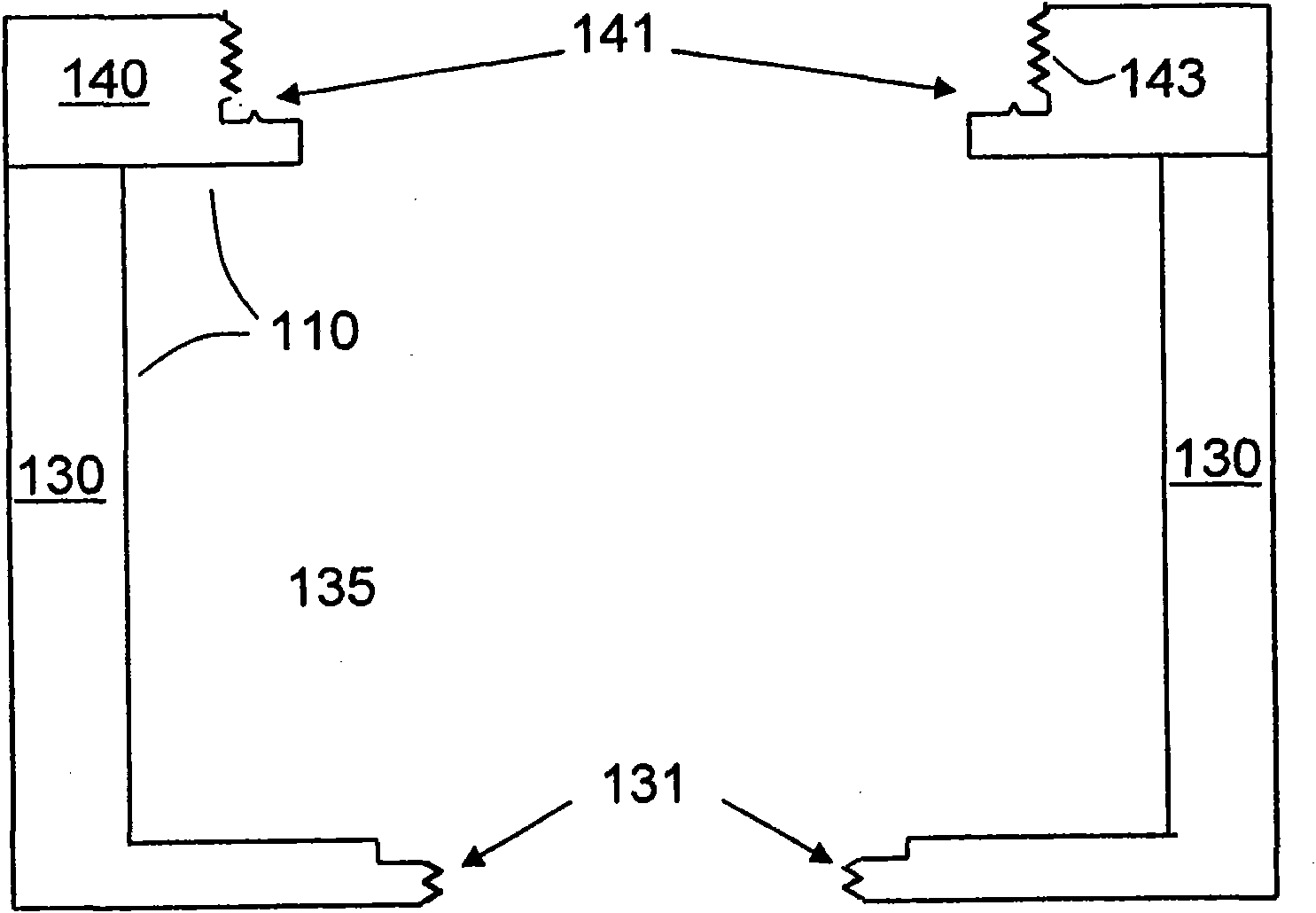

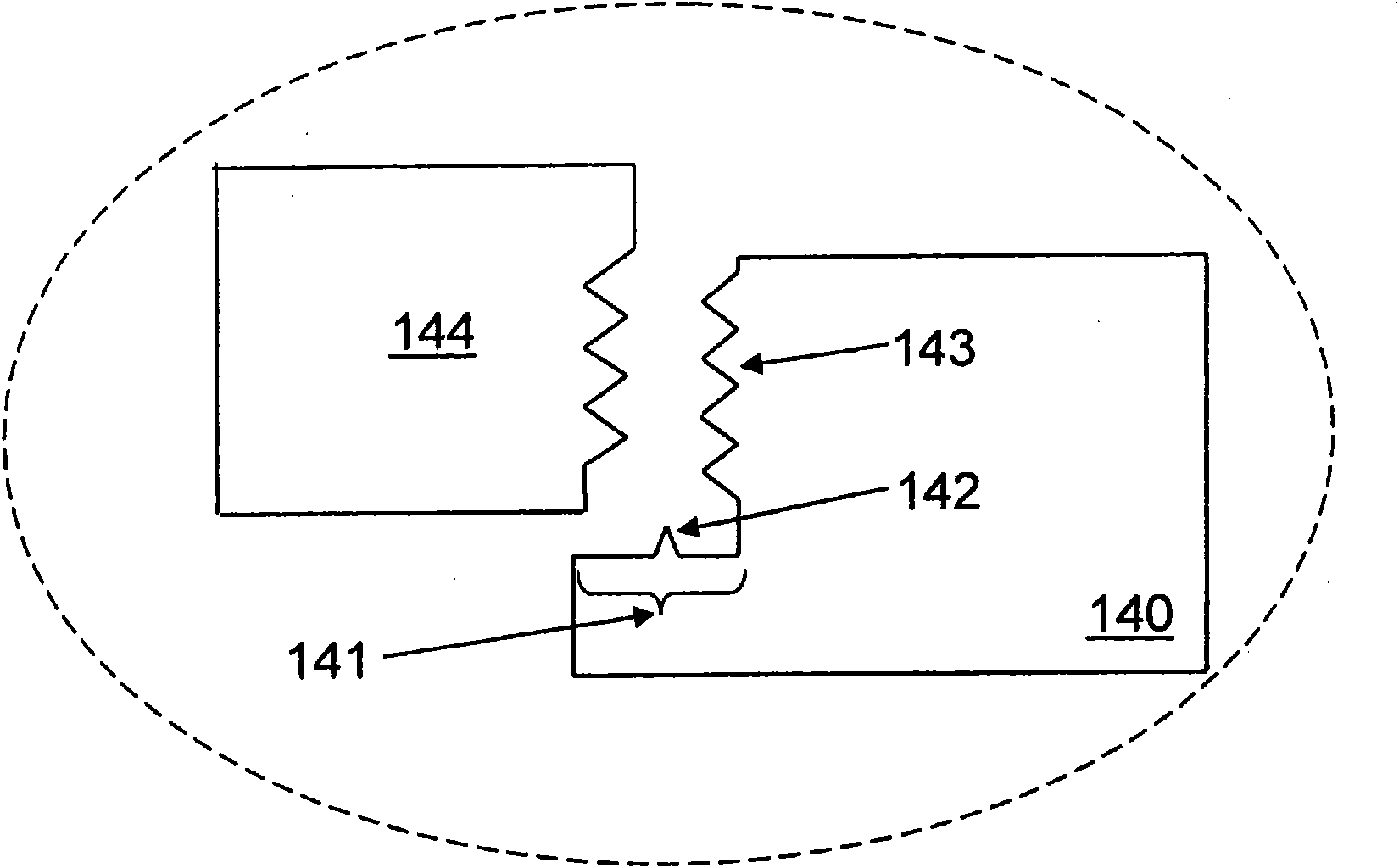

[0034] figure 2 A cross-section of the filter chassis 110 is depicted. The filter chassis 110 may include a filter housing 130 , a filter cavity 135 , and a filter cover 140 . Examples of filter housing 140 may be, for example, a cover, cap, or cover. The filter housing 130 may be adapted to be provided with a filter housing 140 . The filter housing 130 and the filter housing 140 may be made of silver-plated copper o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com