Repairable type milling cutter and integrated repair device

A blade and gas shunt technology, which is applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of difficult repair of repairable milling cutter blades, large performance degradation, etc., to achieve good sharpening effect, short sharpening time, The effect of high-quality machined surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

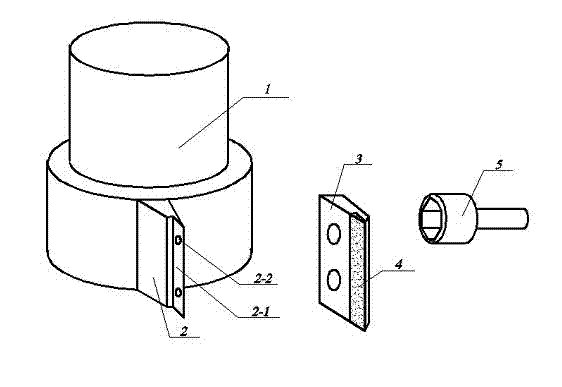

[0024] Such as figure 1 shown.

[0025] A repairable milling cutter, which is mainly composed of a tool holder 1, a blade attachment frame 2 and a repairable blade 3, the blade attachment frame 2 is fixedly connected with the tool holder 1, and the repairable blade 3 is installed on the blade attachment frame 2. A layer of diamond film 4 is deposited on the repairable blade 3; a groove 2-1 and a threaded hole 2-2 on the side of the groove are opened on the blade attachment frame 2, and the repairable blade 3 is inserted into the groove 2-1 and It is fastened on the blade attachment frame 2 by hexagon socket head screws 2-3. The blade holder 1 and the blade attachment frame 2 can be of a split structure or an integral structure, and the number of blade attachment frames 2 on each blade holder 1 can be selected according to actual needs.

Embodiment 2

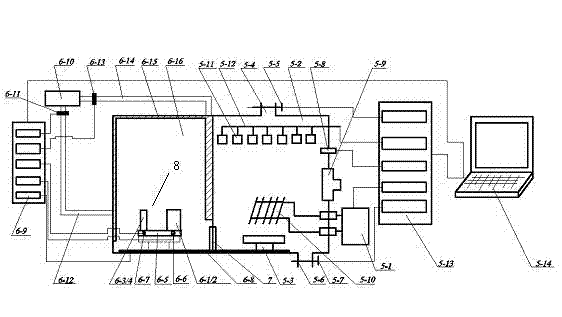

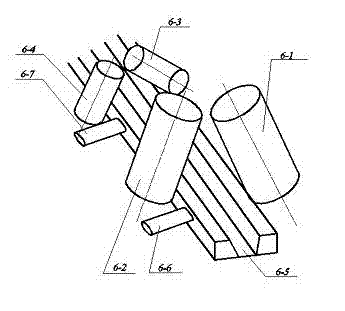

[0027] Such as figure 2 , 3 shown.

[0028] An integrated deposition and sharpening repair device for a repairable blade, which is mainly composed of a diamond deposition film studio 5 and a blade sharpening studio 6. The diamond deposition film studio 5 is equipped with a repairable blade 3 for diamond deposition. The workbench 5-3, the workbench 5-3 is installed on the workbench guide rail 6-8, the workbench guide rail 6-8 extends from the diamond deposition film studio 5 to the blade sharpening studio 6, and the diamond deposition film work A door 7 for the workbench 5-3 to pass is provided between the chamber 5 and the blade sharpening studio 6, and a sharpening device 8 is installed in the blade sharpening studio 6. Such as figure 2 As shown, the diamond deposition film studio 5 includes a power supply 5-1, a gas inlet 5-4, a vacuum exhaust port 5-6, a furnace pressure gauge 5-8, a non-deformable hot wire device 5-10 and a gas split distributor 5-11, the power supp...

example 1

[0033] Example 1: the blade grinding equipment of the present invention is used to sharpen each blade, and the sharpening time is 5 minutes, while the traditional milling cutter utilizes an emery wheel to sharpen each blade for 10 minutes, and the grinding equipment of the present invention is used It can save 50% of the sharpening time, greatly improving the efficiency, and the sharpening does not need to be held by the staff, and it is all automatic, which improves the safety of sharpening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com