Decorative veneering composite board

A composite board and decorative surface technology, applied in the field of composite boards, can solve problems such as labor-intensive, time-consuming, and increased application costs, and achieve the effects of wide application range, simplified construction process, and various varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

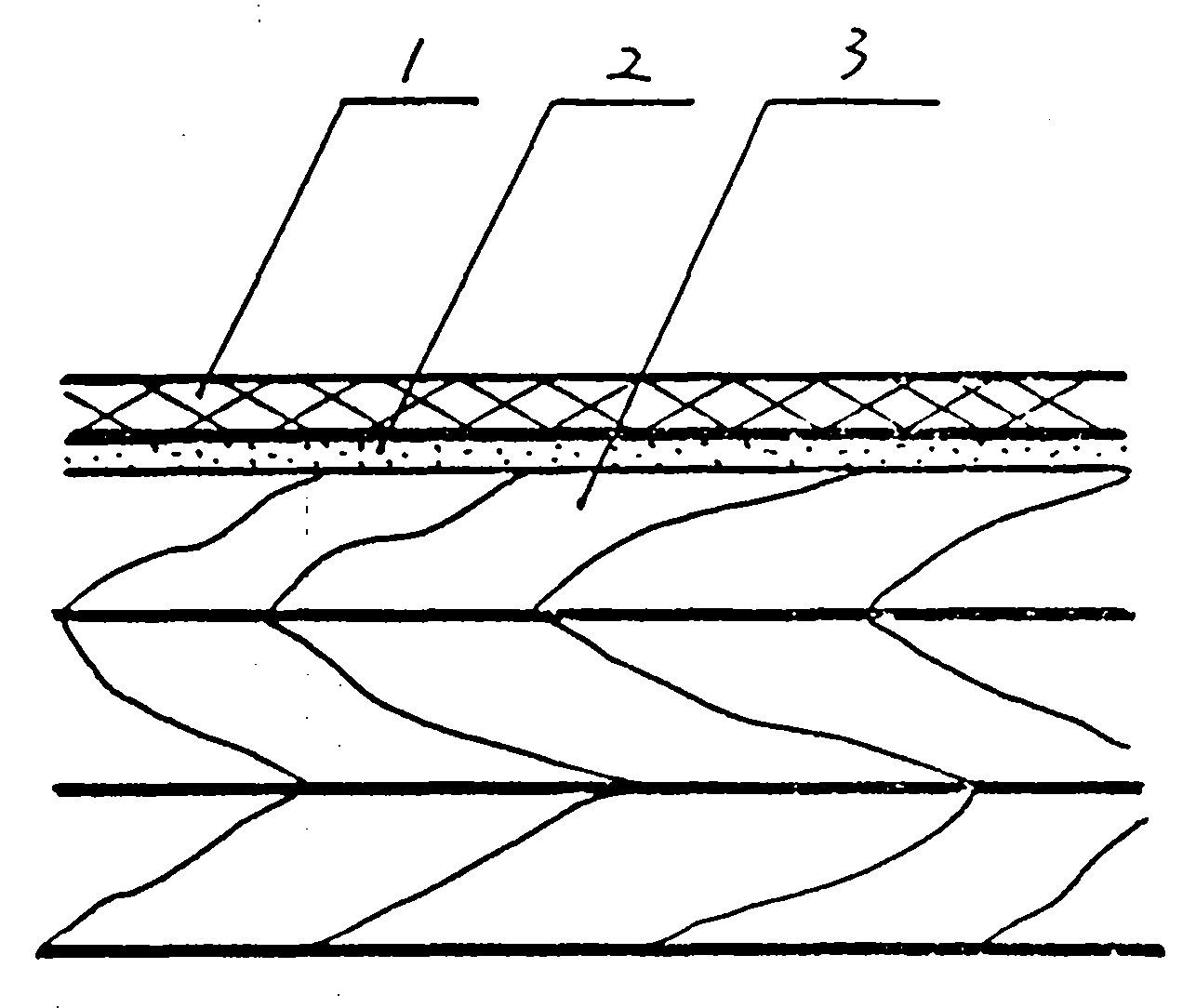

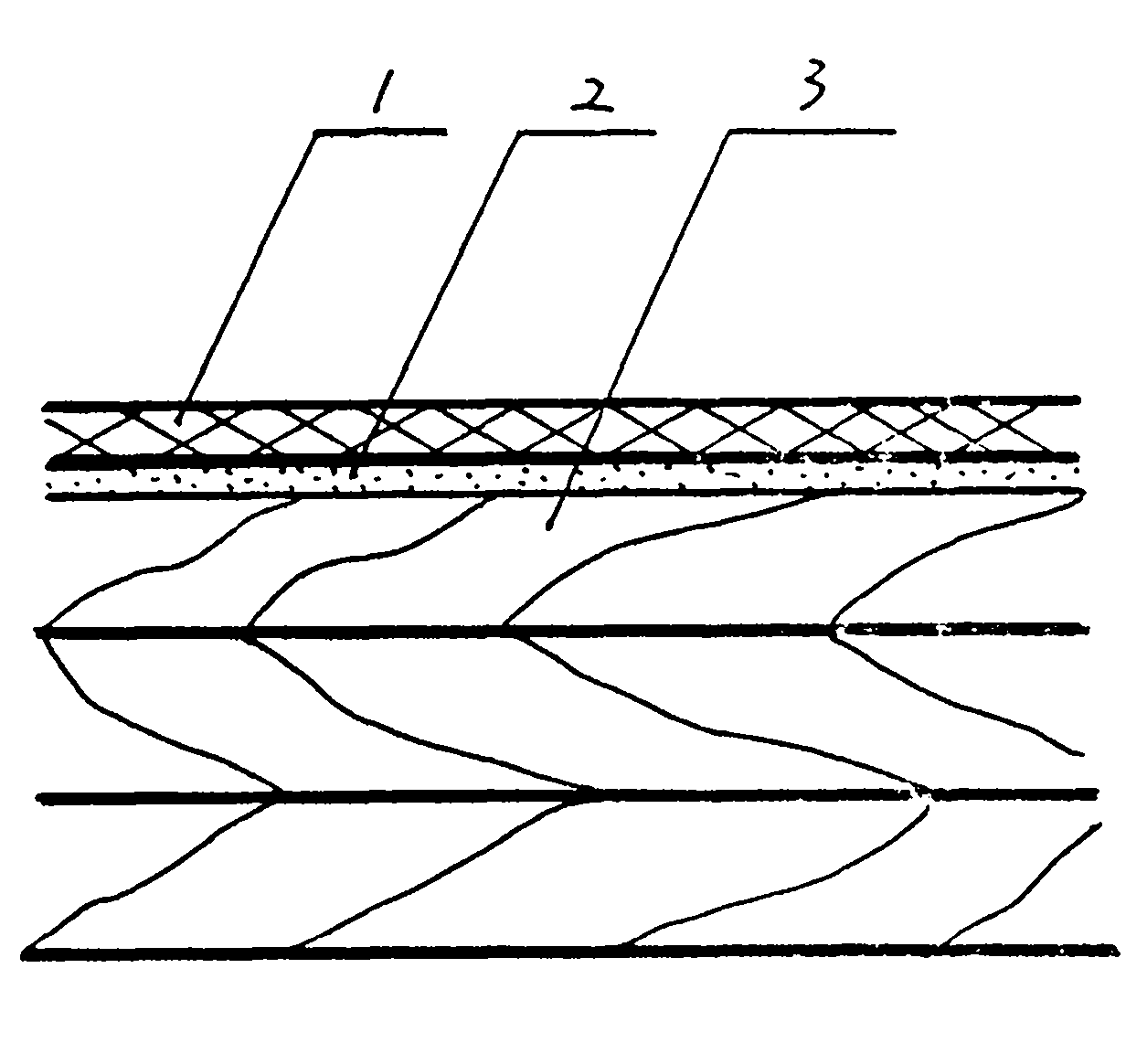

Image

Examples

Embodiment 1

[0009] Embodiment 1 selects blockboard with a thickness of 20mm as the composite board, and the decorative surface selects woven linen for composite, and the composite pressure is 12 kilograms / cm 2 , the adhesive is made of E1 grade MVF resin glue, the sizing ratio is 1:0.04, plus 0.7% paraffin water repellent and weak acid curing agent, the glue is sized by a spiral sizing machine, the sizing temperature is 50 ℃, and the drying temperature The temperature is 80°C, and the drying time is 2 hours.

Embodiment 2

[0010] Embodiment 2, select 5 layers of plywood as the sheet material of this composite board, the decorative surface selects gold silk chemical fiber cloth to carry out composite, and composite pressure is 13 kilograms / cm 2 , the adhesive is made of general-purpose urea-formaldehyde resin glue, the sizing ratio is 1:0.05, and 0.7% paraffin water repellent and weak acid curing agent are added, and the screw sizing machine is used for sizing. The sizing temperature is 45°C, and the drying temperature The temperature is 85°C, and the drying time is 1.5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com