Liquid crystal aligning agent, liquid crystal aligning film and liquid crystal display device

A technology of liquid crystal alignment agent and carbon number, applied in liquid crystal materials, instruments, optics, etc., can solve the problems of general products without structure and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0210] Hereinafter, the present invention will be described using examples. In addition, compounds used in Examples are as follows.

[0211]

[0212] Anhydride (1): pyromellitic dianhydride

[0213] Anhydride (19): 1,2,3,4-cyclobutanetetracarboxylic dianhydride

[0214] Anhydride (23): 1,2,3,4-butanetetracarboxylic dianhydride

[0215] Anhydride (68): ethylenediaminetetraacetic dianhydride

[0216]

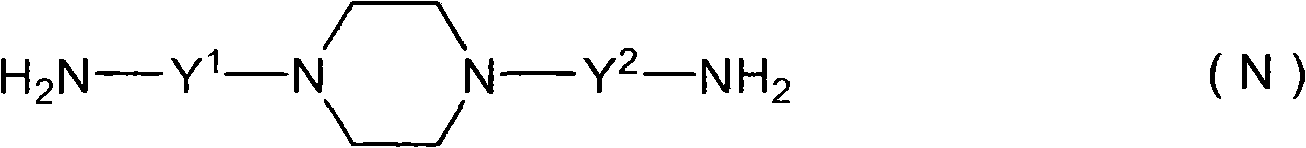

[0217] Diamine (N-3): 1,4-bis(2-aminoethyl)piperazine

[0218] Diamine (N-4): 1,4-bis(3-aminopropyl)piperazine

[0219] Diamine (V-1): 4,4'-diaminodiphenylmethane

[0220] Diamine (V-7): 4,4'-diamino-1,2-diphenylethane

[0221] Diamine (V-35): 4,4'-diamino-diphenylamine

[0222] Diamine (VII-13): 2,2-bis(4-(4-aminophenoxy)phenyl)propane

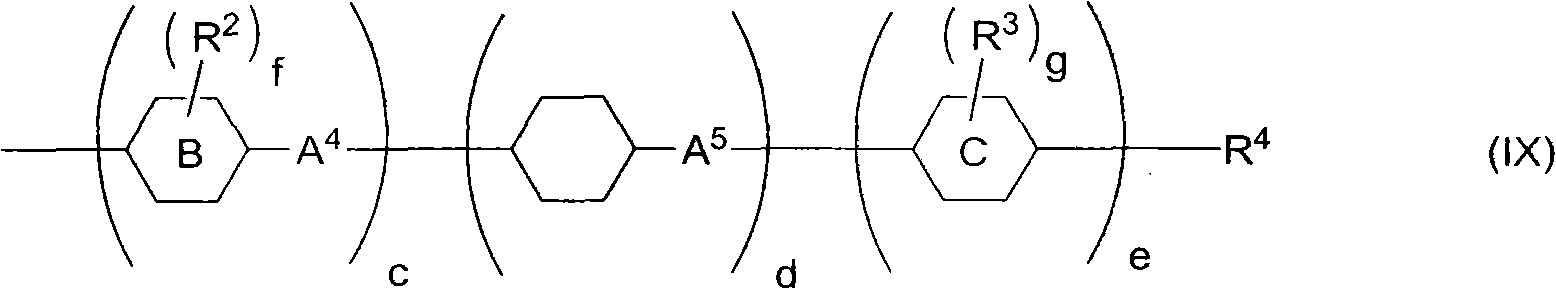

[0223] Diamine (VIII-5-1): 5-[[4-(4'-pentyl[1,1'-bicyclohexyl]-4-yl)phenyl]methyl]-1,3-diamino benzene

[0224] Diamine (XII-2-1): 1,1-bis[4-(4-aminophenyl)methylphenyl]-4-n-heptylcyclohexane

[0225] Diamine (XII-4-1): 1,1-bis[4-(...

Synthetic example 1

[0239] In a 100mL four-necked flask equipped with a thermometer, a stirrer, a raw material inlet and a nitrogen inlet, add 0.8242g of compound (XII-4-1), 2.1686g of compound (V-1) and 0.2739g of compound (N -4) and 20.0 g of dehydrated NMP were stirred and dissolved under a stream of dry nitrogen. Next, 0.4473 g of compound (1), 1.6088 g of compound (19), 0.6772 g of compound (23) and 50.0 g of dehydrated NMP were added, and reacted at 75° C. for 8 hours and then at room temperature for 15 hours. 24.0 g of BC was added to the obtained solution, and the polyamic-acid solution whose density|concentration of the polymer solid content (hereinafter abbreviated as polymer solid content) containing an unreacted monomer and a by-product was 6 weight% was obtained. Let this polyamic acid be PA1. The weight average molecular weight of PA1 was 25,100.

[0240] The weight-average molecular weight of polyamic acid is obtained by the following method: the obtained polyamic acid is diluted...

Synthetic example 2~17

[0242] Except having changed tetracarboxylic dianhydride and diamine to what is shown in Table 1, polyamic-acid solution (PA2)-(PA17) was prepared according to the synthesis example 1. The results including Synthesis Example 1 are summarized in Table 1.

[0243] Table 1

[0244]

[0245] Table 1 (continued)

[0246]

[0247]

[0248] The liquid crystal alignment agent was left to stand in a freezer at -20° C. for one month. At this time, it was judged as “failure” when polymer precipitation was observed, and “good” when no polymer precipitation was observed.

[0249] Table 2

[0250] Polyamic acid solution No.

[0251] PA8

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com