Photo-acoustic spectrum gas detecting system based on distributed feedback optical fiber laser

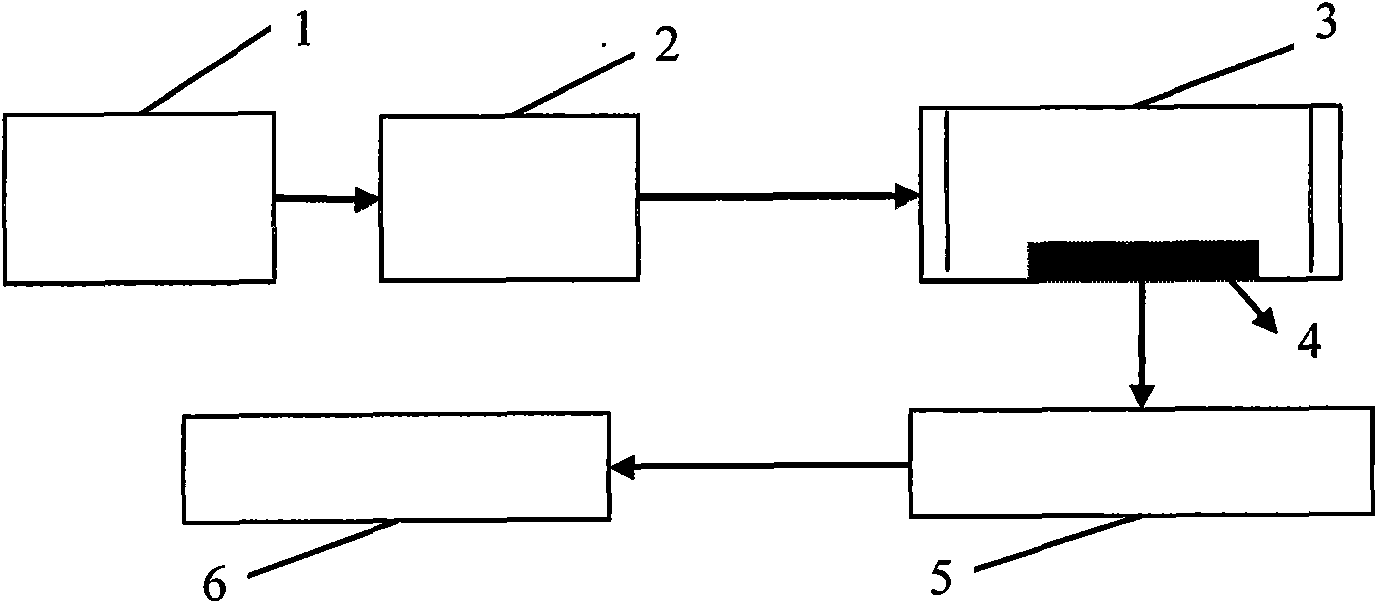

A fiber laser and distributed feedback technology, which is applied in the field of photoacoustic gas detection system, can solve the problems of limited detection technology, loss of detection equipment function, and influence on measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

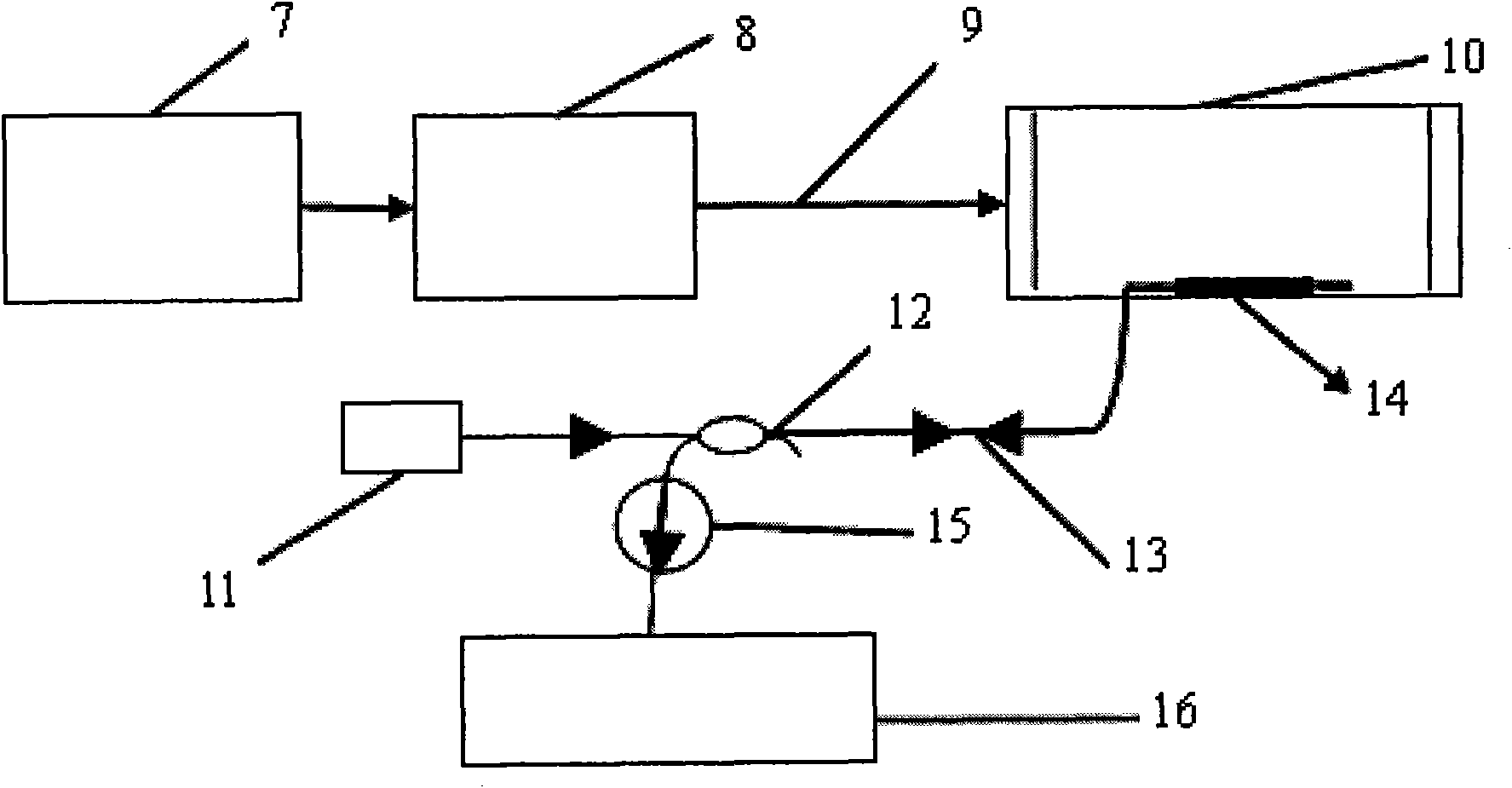

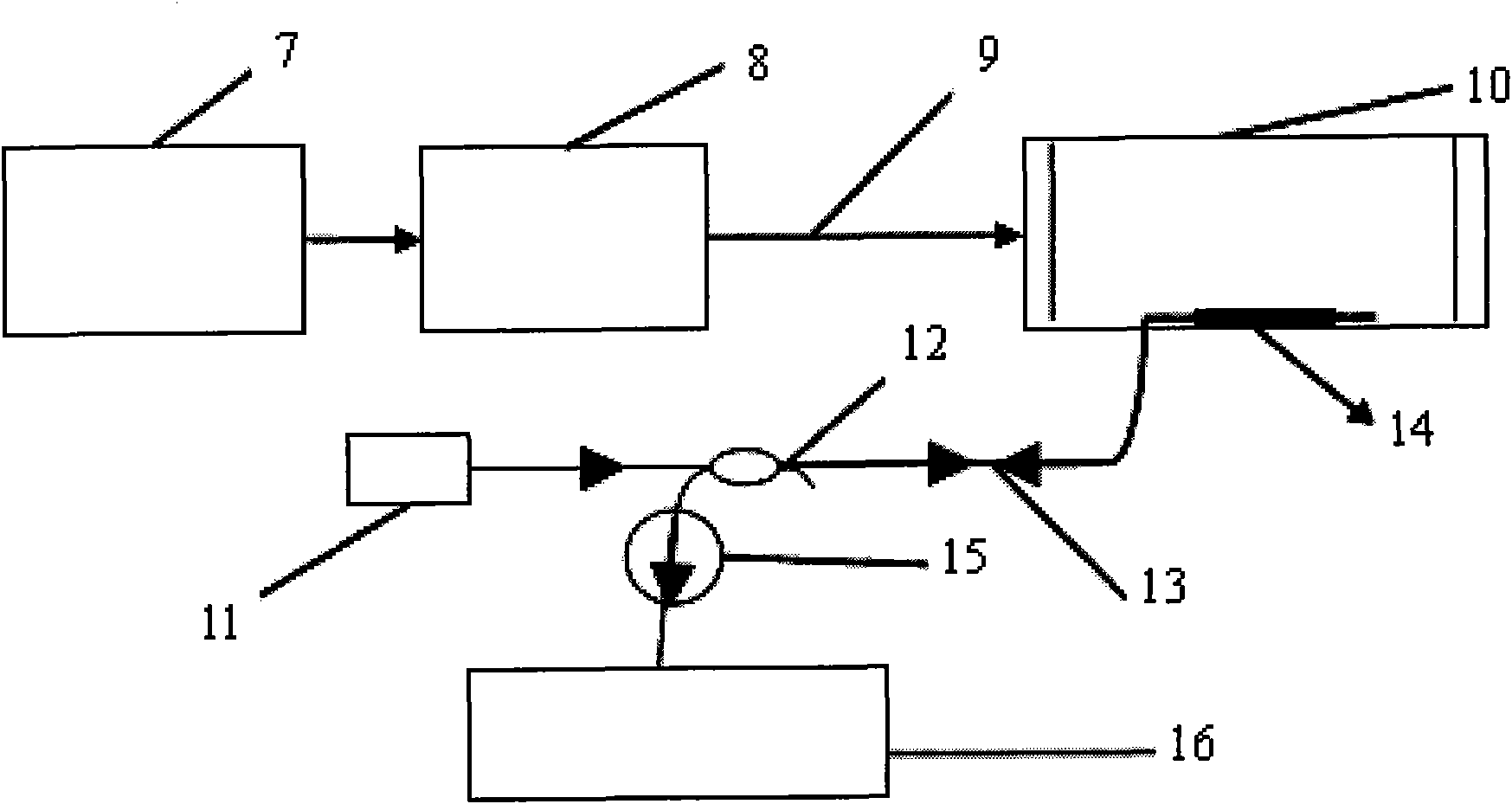

[0019] Examples of the present invention figure 2 As shown, it includes a coherent light source 7, a modulator 8, a photoacoustic cell 10, a 980 pump semiconductor laser (LD) 11, a wavelength division multiplexer (WDM) 12, a distributed feedback fiber laser (DFB-FL) 14, and an isolator (ISO) 15 and the wavelength demodulation system 16, the coherent light source 7 is connected with the modulator 8 through its own pigtail, and the modulator 8 is connected to the far-end photoacoustic pool 10 through a longer common optical fiber 9, and the light intensity period of the output The changing laser acts on the gas to be tested to generate a tiny sound, which constitutes the sound signal excitation optical path; the 980 pump semiconductor laser (LD) 11 is connected to the 980nm end of the wavelength division multiplexer (WDM) 12 through a pigtail and the subsequent optical path Form the detection optical path, it is characterized in that distributed feedback fiber laser (DFB-FL) 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com