Embedded real-time emulation and fault simulation system based on multiple data buses

A data bus and real-time simulation technology, applied in electrical testing/monitoring, etc., can solve problems such as multi-channel timer clock deviation, bus timing start deviation, transmission asynchronous, etc., to improve authenticity, overcome clock deviation, and equipment volume The effect of low weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

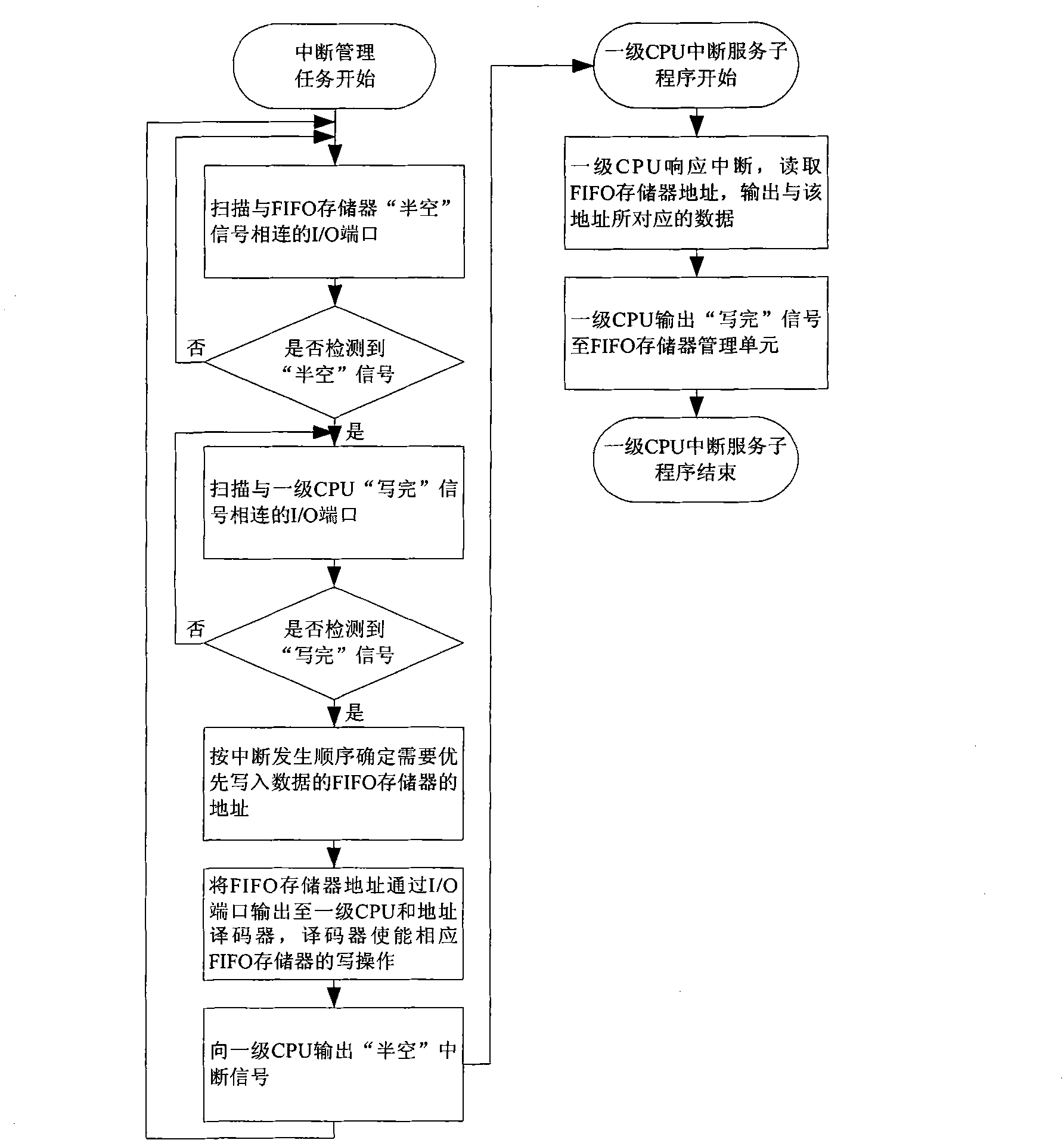

[0041] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

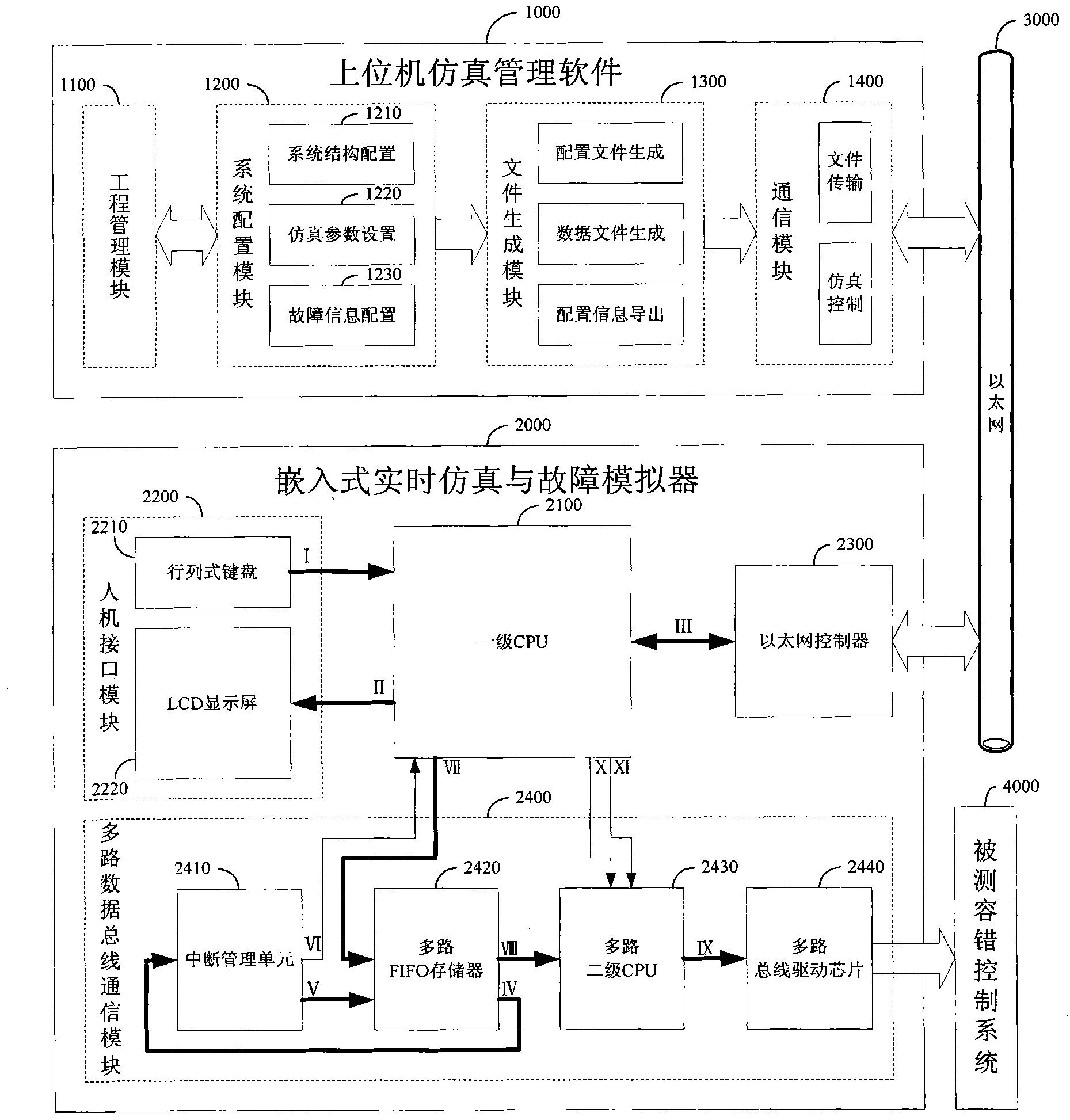

[0042] The present invention is an embedded real-time simulation and fault simulation system based on multi-channel data bus, such as figure 1 As shown, it includes host computer simulation management software 1000 and embedded real-time simulation and fault simulator 2000 .

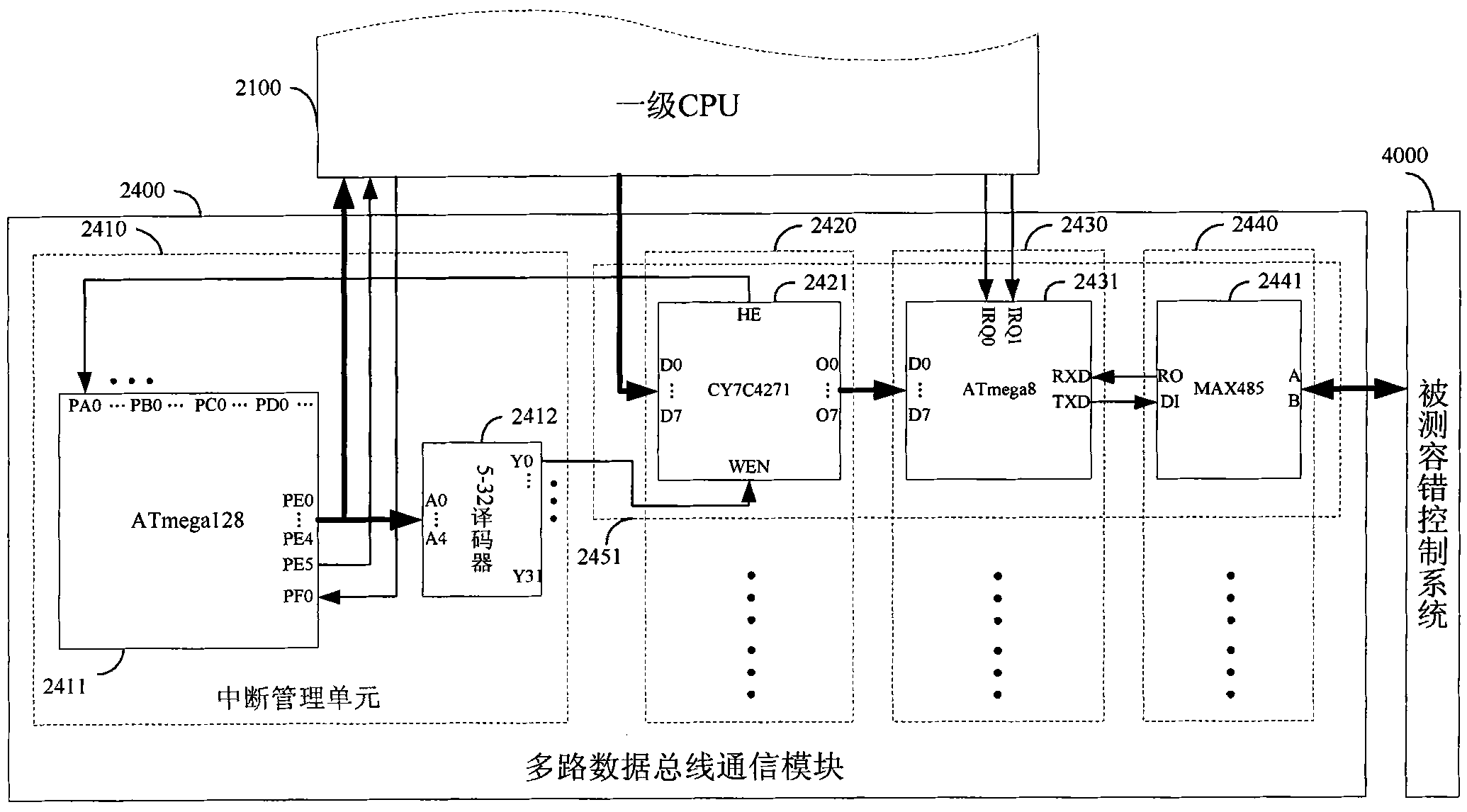

[0043] The data bus can be various types of serial data buses, such as RS-485 bus, CAN bus, 1553B bus, etc., which are commonly used in aerospace electrical systems. The following uses embedded real-time simulation and fault simulation based on 32 RS-485 buses The system is described as an example of a specific implementation of the present invention, and the implementation is also applicable to similar systems of different types of buses and different numbers of interfaces.

[0044] The host computer simulation management software 1000 runs on a general-purpose computer and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com