Therapeutic agent for fibromyalgia syndrome and therapeutic agent for pain due to vascular smooth muscle spasm

A technology for vascular smooth muscle and fibromyalgia, which is used in cardiovascular system diseases, non-central analgesics, anti-inflammatory agents, etc., to achieve the effect of inhibiting thrombosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0122] Production Example 1. Production of RNA

[0123] (1) Slurry yeast recovered from the beer manufacturing process was passed through a sieve of 80 to 200 meshes to remove solid content, washed with 0.5% to 1% aqueous sodium carbonate solution, and washed with water to obtain debittering yeast.

[0124] (2) Add salt and water so that the yeast concentration is 10%, and the salt concentration is 10%, heat up and boil for 2 to 5 hours. The boiling conditions can be replaced by autoclaving for 1 hour.

[0125] (3) Extract ribonucleic acid under boiling, then cool, and perform solid-liquid separation with a centrifuge or the like to obtain an extract. The RNA remaining in the solid fraction was washed with 10% saline, and the washed solution was recovered and combined with the previous extraction solution.

[0126] (4) Concentrated hydrochloric acid was added to the extract to adjust the pH to 2 to obtain a fraction that precipitated under acidic conditions. The precipitate...

manufacture example 2

[0127] Production Example 2. Production of RNA

[0128] Add 450L of water to 90kg of dry beer yeast and stir for a certain period of time to dissolve the inclusions and wash the yeast. Next, centrifugation was performed to recover the washed yeast, and 800 L of water and 90 kg of salt were added for heating. Boil for 2 hours, and then use a centrifuge to obtain an extract. For the ribonucleic acid remaining in the residue, add 10% saline, and recover the washing solution. The extracts were pooled and subjected to the same treatment as in (4) and subsequent steps of RNA Production Example 1 to obtain brewer's yeast crude RNA.

manufacture example 3

[0129] Production Example 3. Production of RNA

[0130] The pulpy brewer's yeast is subjected to debittering washing by a conventional method, and dried with a drum dryer at 120-140°C. 10 times the amount of hot water above 95° C. was added to the dry beer yeast, kept for 5 minutes, and then solid-liquid separation was performed to obtain a solid substance. Add salt and water to the solid matter, adjust the concentration of beer yeast solid matter to 10%, and the concentration of salt to 10%. In order to break the cell wall, put it into a homogenizer so that the ejection pressure is 600kg / cm 2 above. The treatment solution containing the crushed yeast was heated and boiled for 2 to 5 hours, and the same treatment as that in (3) and subsequent steps of RNA production example 1 was performed to obtain brewer's yeast crude RNA.

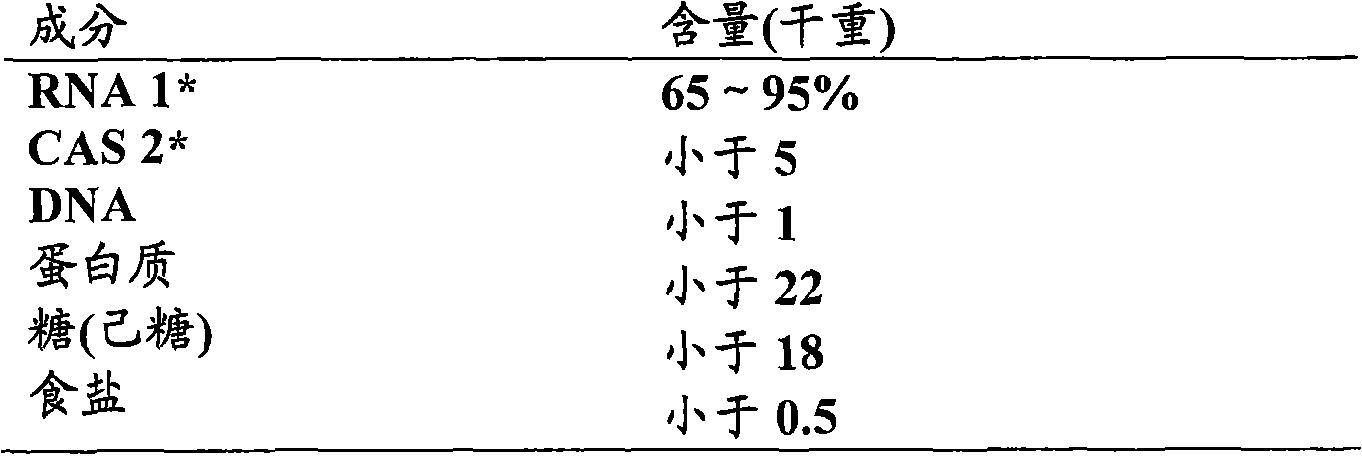

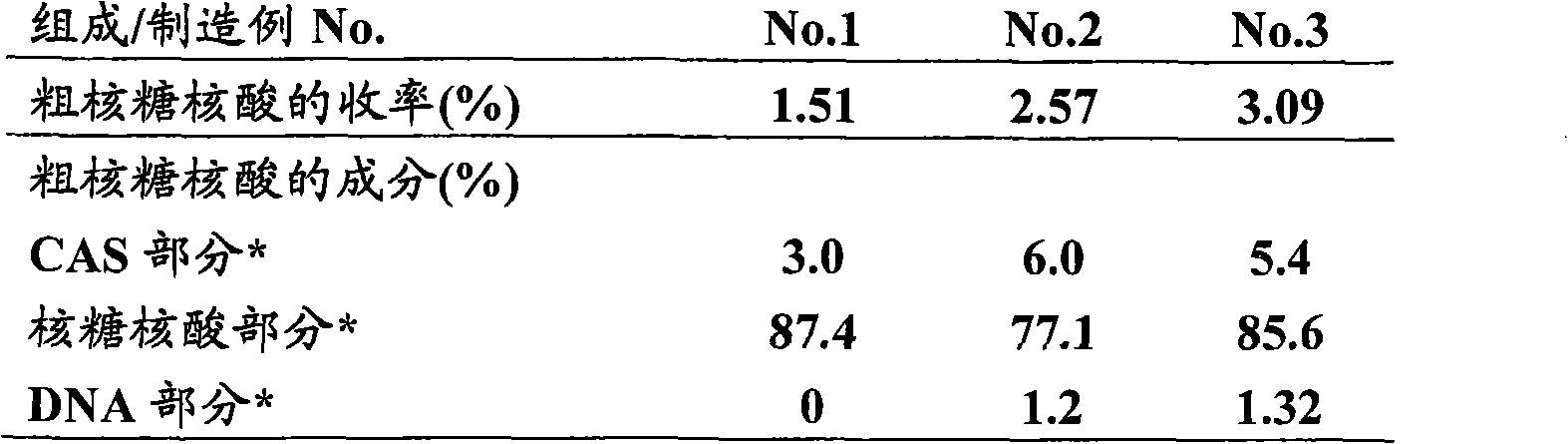

[0131] The following table shows the compositional analysis results of the crude RNA obtained in these production examples.

[0132] [Table 2]

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com