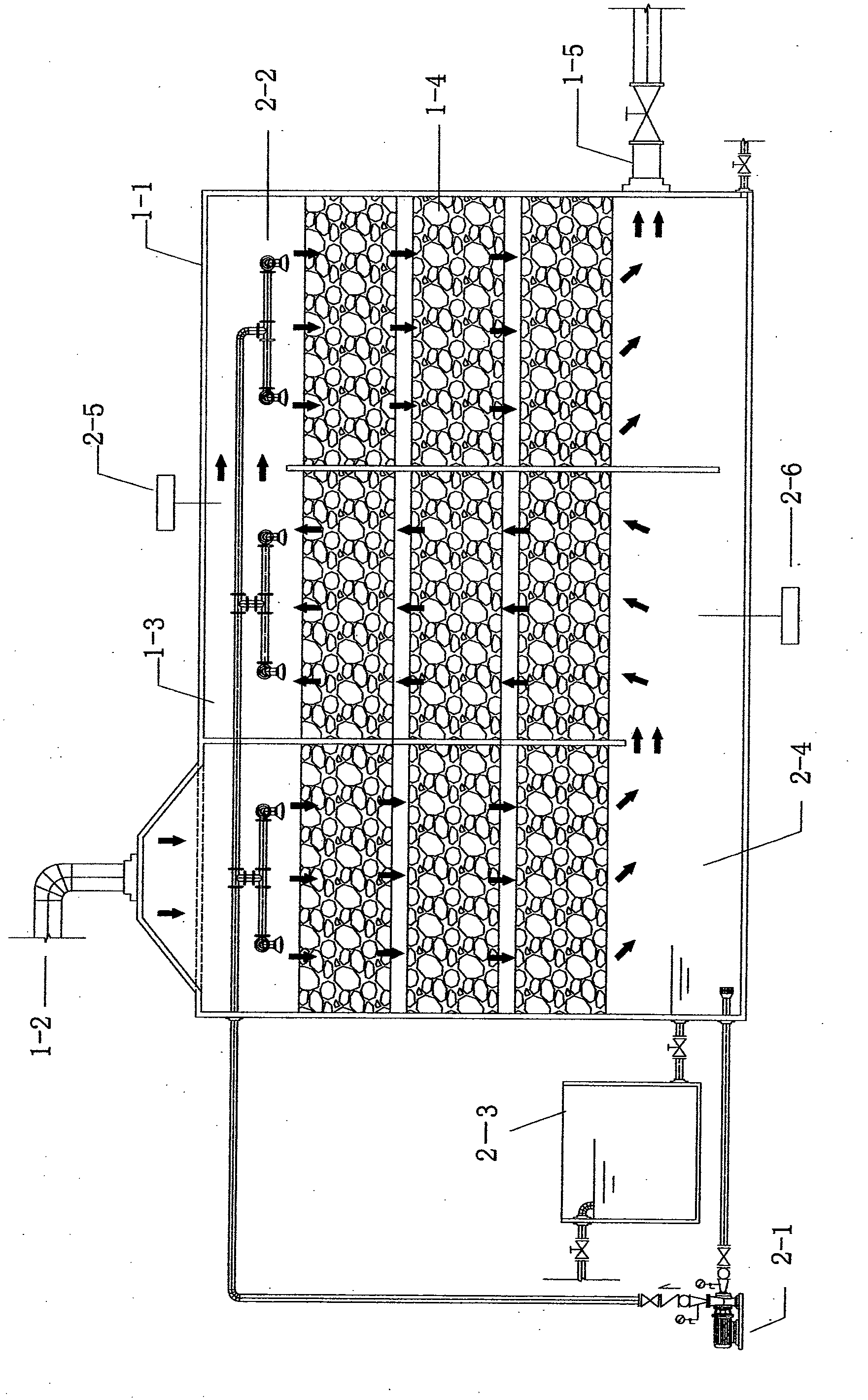

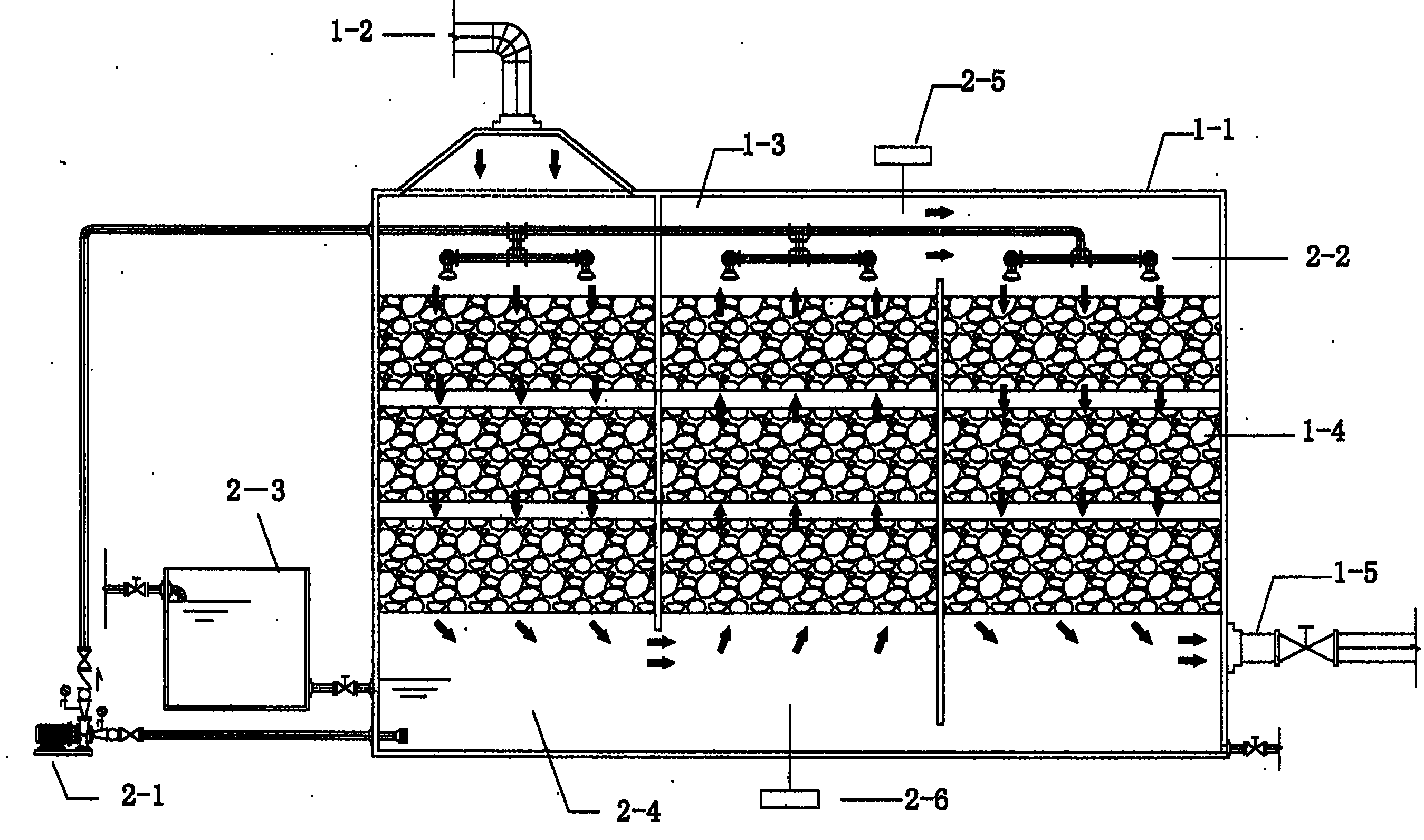

Biofilter tower exhaust gas purification system

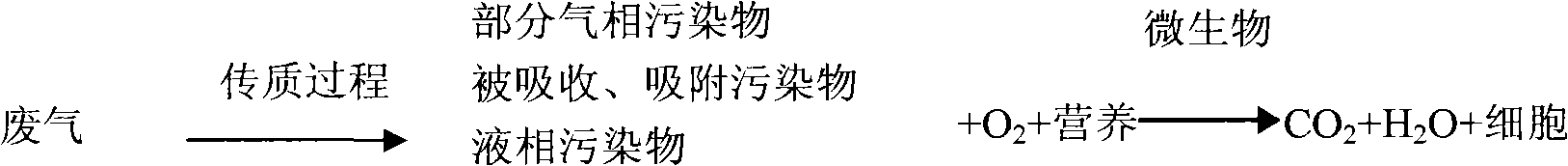

A waste gas purification system and biological filter tower technology, which is applied in the fields of air quality improvement, chemical instruments and methods, and separation of dispersed particles, can solve the problems of short residence time and contact time with microorganisms, poor resistance to high-concentration toxic pollutants, and purification effect Bad question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] With the continuous development of urban construction and the continuous expansion of the city scale, the location of the sewage treatment plant is getting closer and closer to the residential area. The odor emitted by the sewage treatment plant during operation will seriously affect the normal life of the surrounding residents, thus causing environmental pollution. Pollution problems are also increasing. The sewage treatment plant in a certain city is an old plant with a history of 20 years. Like many old sewage plants in China, the pollution of foul gas was not considered because the plant was surrounded by fish ponds and wasteland in the early stage of construction. The sewage treatment plant is now the center of the city, and its odor pollution problem has brought great troubles to the surrounding residents. At the same time, it is also very inconsistent with the beautiful city appearance. Therefore, it is necessary to solve the odor pollution of the sewage treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com