Continuous and uniform blanking device and method for flame melt method gem sintering machine

A method of gemstone and sintering machine, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of waste of resources, large specific gravity, discontinuous blanking, etc., and achieve the effect of strong fluidity and large specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

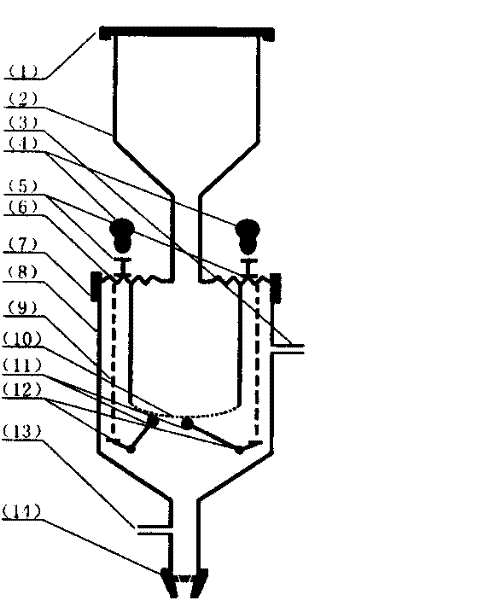

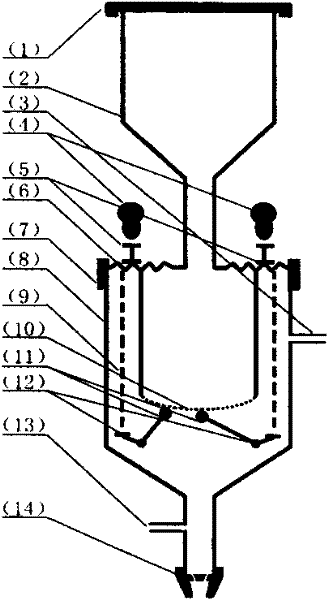

[0009] This embodiment refers to figure 1 , inject gem raw material powder into the main hopper (2), tighten the sealed main hopper cover (1), adjust the main hopper hammer (4) through the speed regulating motor and transmission device, and cause the material in the main hopper to drop to the screen (10), when the material does not fall, increase the force of the main hopper knocking hammer (4), through the rigid circular transmission device with holes (9) and the connecting rod and fixing device of the screen knocking hammer ( 12) Cause the sieve knocking hammers (11) to undulate and knock the sieves against each other to achieve even and continuous blanking, then the materials are brought to the oxyhydrogen flame nozzle (14) through the oxygen pipe (3) and the hydrogen pipe (13).

[0010] The sealed hopper cover (1) can prevent the hydrogen and oxygen from tempering when the powder falls off. The hammer (4), spring leaf (5), corrugated plate (6), nut (7) and auxiliary hopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com