Elastoplastic equivalent material and preparation method thereof

A similar material, elastoplastic technology, applied in the field of similar materials and their preparation, can solve problems such as difficult to realize, and achieve the effects of easy processing, stable mechanical properties, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

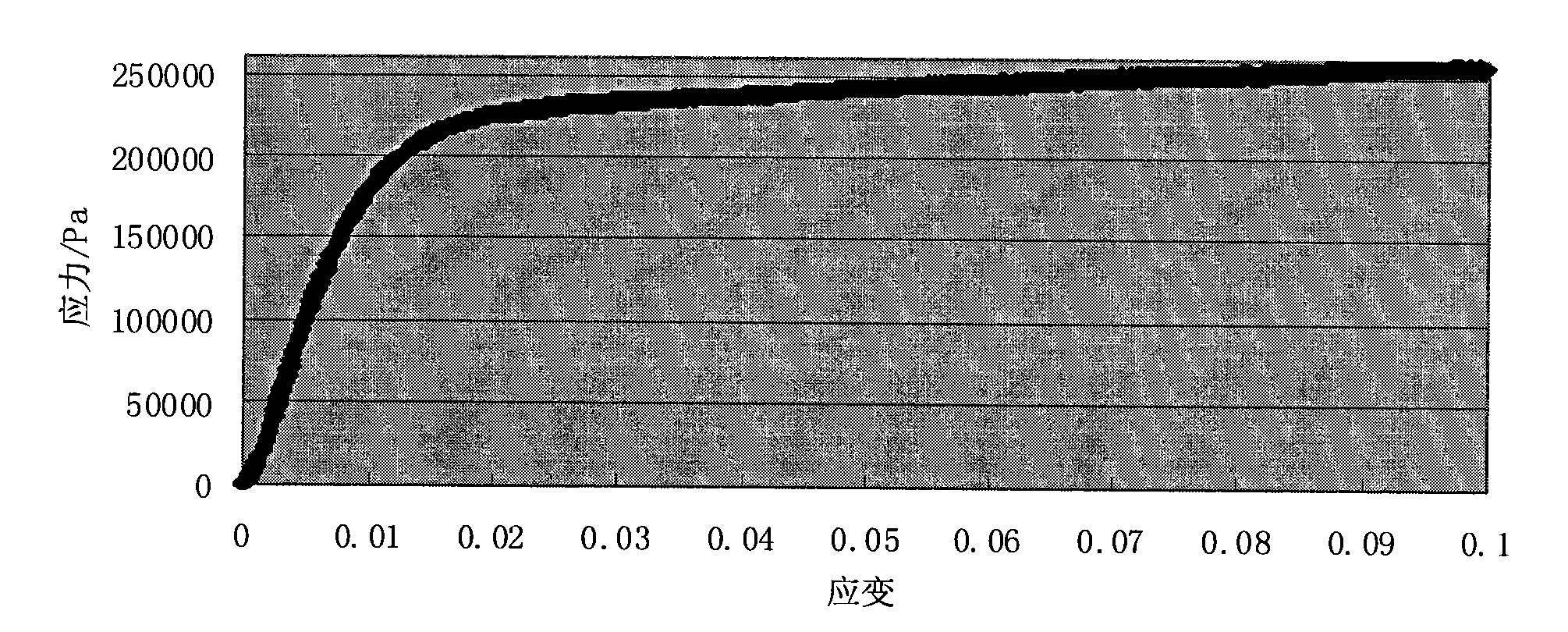

Embodiment 1

[0020] Embodiment one, weigh by mass proportioning:

[0021] 100 parts of paraffin;

[0022] Vaseline 80 parts;

[0023] 60 parts of powdered rubber.

[0024] First put 100 parts of paraffin wax and 80 parts of Vaseline weighed according to the mass ratio into a stainless steel cup, then put the stainless steel cup into an oven to heat, adjust the temperature of the oven to 80 degrees Celsius, and after heating for about 8 hours, vaseline and The paraffin is completely melted into a mixed liquid. At this time, take out the stainless steel cup and stir it with a mixer. Stir the mixture of paraffin wax and Vaseline for 1 to 2 minutes, then slowly add 60 parts of powdered rubber while stirring, and continue stirring after adding the powdered rubber. After about 5 minutes until uniform, stop stirring, pour the mixture in the stainless steel cup into the mold, cool at room temperature for about 24 hours, and remove the mold.

[0025] For the convenience of the test, the mold use...

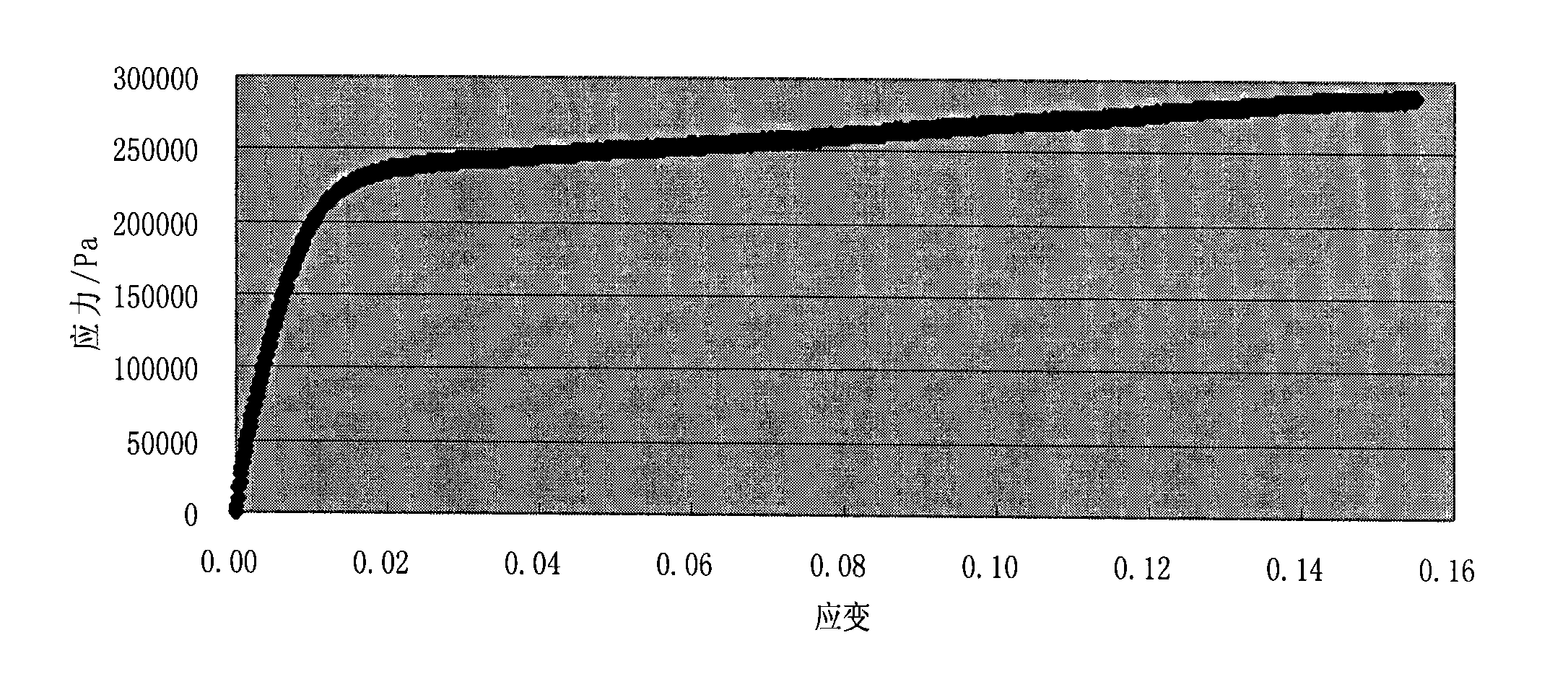

Embodiment 2

[0026] Embodiment two, weigh by mass proportioning:

[0027] 100 parts of paraffin;

[0028] Vaseline 50 parts;

[0029] Powder rubber 100 parts.

[0030] First put 100 parts of paraffin and 50 parts of Vaseline weighed according to the mass ratio into a stainless steel cup, then put the stainless steel cup into an oven to heat, adjust the temperature of the oven to 120 degrees Celsius, and after heating for about 5 hours, Vaseline and The paraffin is completely melted into a mixed liquid. At this time, take out the stainless steel cup and stir it with a mixer. Stir the mixture of paraffin wax and Vaseline for 1 to 2 minutes, then slowly add 100 parts of powdered rubber while stirring, and continue stirring after adding the powdered rubber. About 10 minutes until uniform, stop stirring, pour the mixture in the stainless steel cup into the mold, cool at room temperature for about 24 hours, and remove the mold.

[0031] In this embodiment, a cylindrical mold is also used, and...

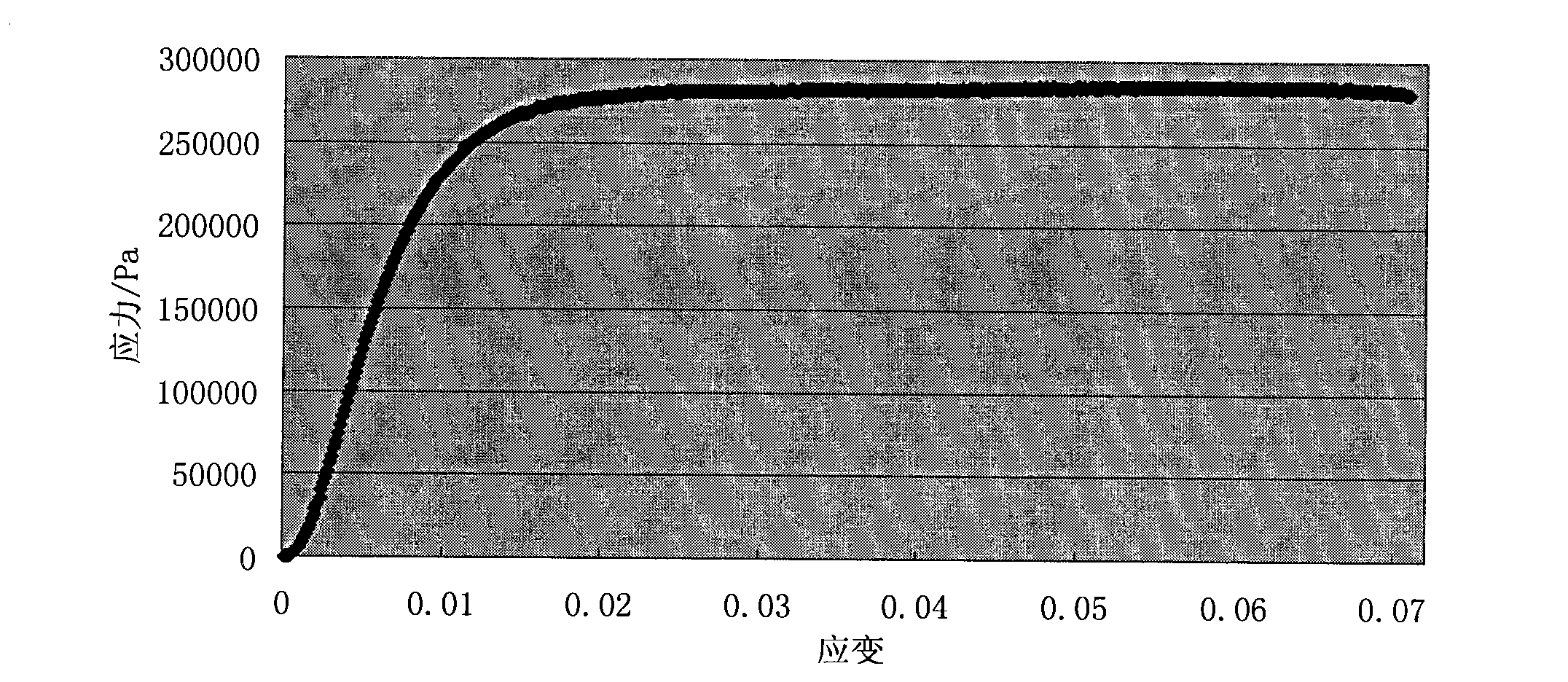

Embodiment 3

[0032] Embodiment three, weigh by mass proportioning:

[0033] 100 parts of paraffin;

[0034] Vaseline 110 parts;

[0035] 50 parts of powdered rubber.

[0036] First put 100 parts of paraffin and 110 parts of Vaseline weighed according to the mass ratio into a stainless steel cup, then put the stainless steel cup into an oven to heat, adjust the temperature of the oven to 140 degrees Celsius, and after heating for about 3 hours, Vaseline and The paraffin is completely melted into a mixed liquid. At this time, take out the stainless steel cup and stir it with a mixer. Stir the mixture of paraffin wax and Vaseline for 1 to 2 minutes, then slowly add 50 parts of powdered rubber while stirring, and continue stirring after adding the powdered rubber. About 10 minutes until uniform, stop stirring, pour the mixture in the stainless steel cup into the mold, cool at room temperature for about 24 hours, and remove the mold.

[0037] In this embodiment, a cylindrical mold is also us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com