Fiber composite sand control material and preparation method thereof

A fiber composite and sand control technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of intensified sand production, poor sand control effect, intensified water production, etc., so as to increase the permeability of gas phase and reduce the permeability of water phase. , the effect of reducing water production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Select 5g of ceramic fibers with a length of 4mm and a diameter of 15um, and add 0.05g of linear methyl hydrogen polysiloxane to make the fibers wet evenly;

[0026] Coating material preparation, mix 25g of modified phenolic resin, 1.25g of linear methyl hydrogen polysiloxane and 0.05g of silicone coupling agent under stirring condition;

[0027] Select 500g of 40-60 mesh Lanzhou quartz sand, wash and air-dry, heat the quartz sand to 60°C, add the coating material mixture (resin, coupling agent and water inhibiting material) under the condition of stirring, and stir to form a uniform mixture . Under the condition of 20°C-30°C, when it is air-dried until it does not stick to each other, add the fiber that has been treated with water suppression, continue to stir evenly, and air-dry thoroughly, and the fiber composite sand control material is prepared.

Embodiment 2

[0029] Select 5g of ceramic fibers with a length of 6mm and a diameter of 20um, and add 0.075g of linear methylhydrogenpolysiloxane to make the fibers wet evenly;

[0030] Coating material preparation, mix 37.5g modified phenolic resin, 3.75g linear methyl hydrogen polysiloxane and 0.3g silicone coupling agent under stirring condition;

[0031] Select 500g of 40-60 mesh Yixing ceramsite, wash and air-dry, heat the ceramsite to 60°C, add the coating material mixture (resin, coupling agent and water inhibiting material) under the condition of stirring, and stir to form a uniform mixture . Under the condition of 20°C-30°C, when it is air-dried until it does not stick to each other, add the fiber that has been treated with water suppression, continue to stir evenly, and air-dry thoroughly, and the fiber composite sand control material is prepared.

Embodiment 3

[0033] Select 5g of ceramic fibers with a length of 8mm and a diameter of 20um, and add 0.1g of linear methyl hydrogen polysiloxane to make the fibers wet evenly;

[0034] Coating material preparation, mix 50g of modified phenolic resin, 7.5g of linear methylhydrogen polysiloxane and 0.75g of silicone coupling agent under stirring condition;

[0035] Select 500g of 40-60 mesh Lanzhou quartz sand, wash and air-dry, heat the quartz sand to 60°C, add the coating material mixture (resin, coupling agent and water inhibiting material) under the condition of stirring, and stir to form a uniform mixture . Under the condition of 20°C-30°C, when it is air-dried until it does not stick to each other, add the fiber that has been treated with water suppression, continue to stir evenly, and air-dry thoroughly, and the fiber composite sand control material is prepared.

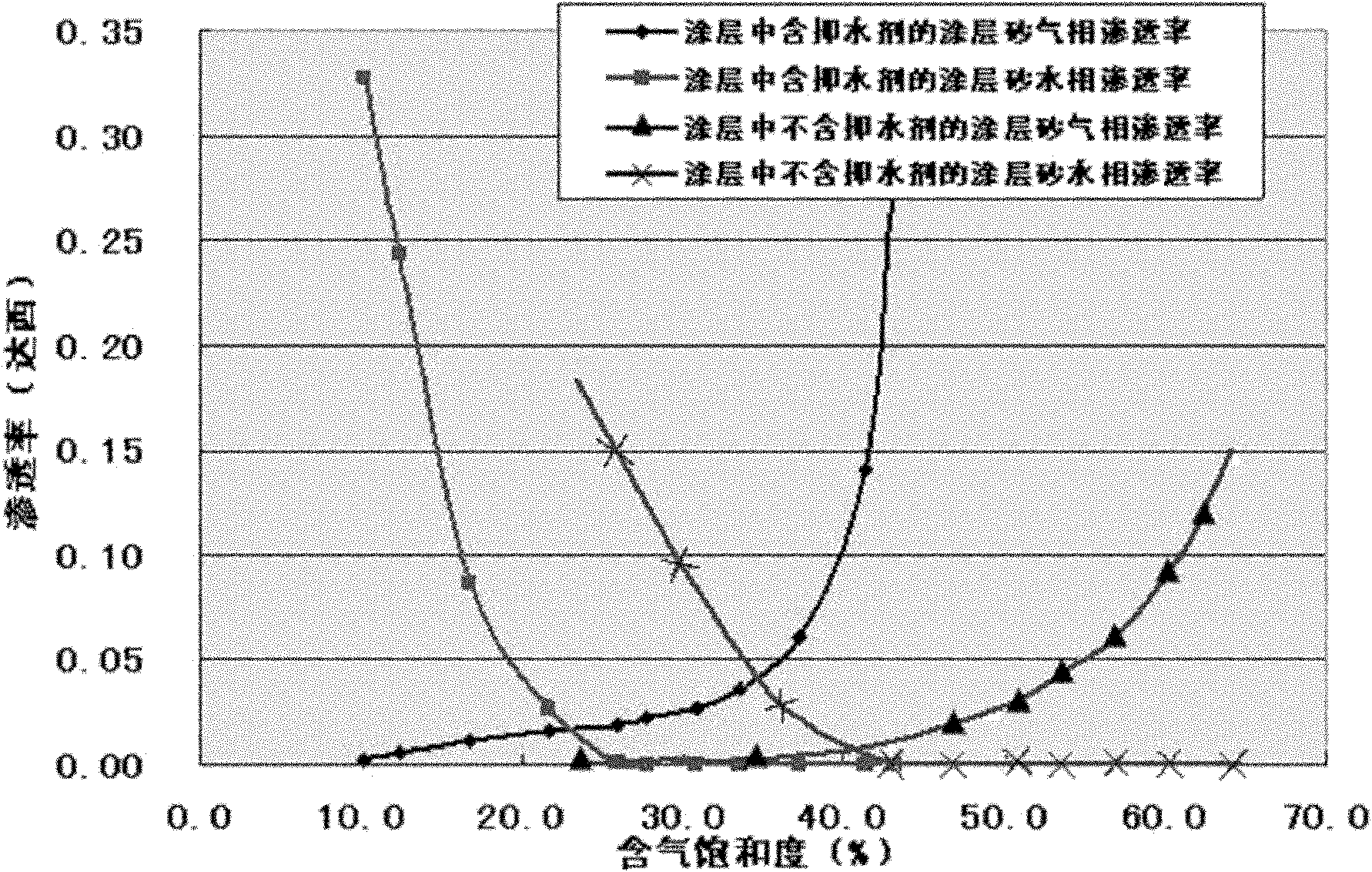

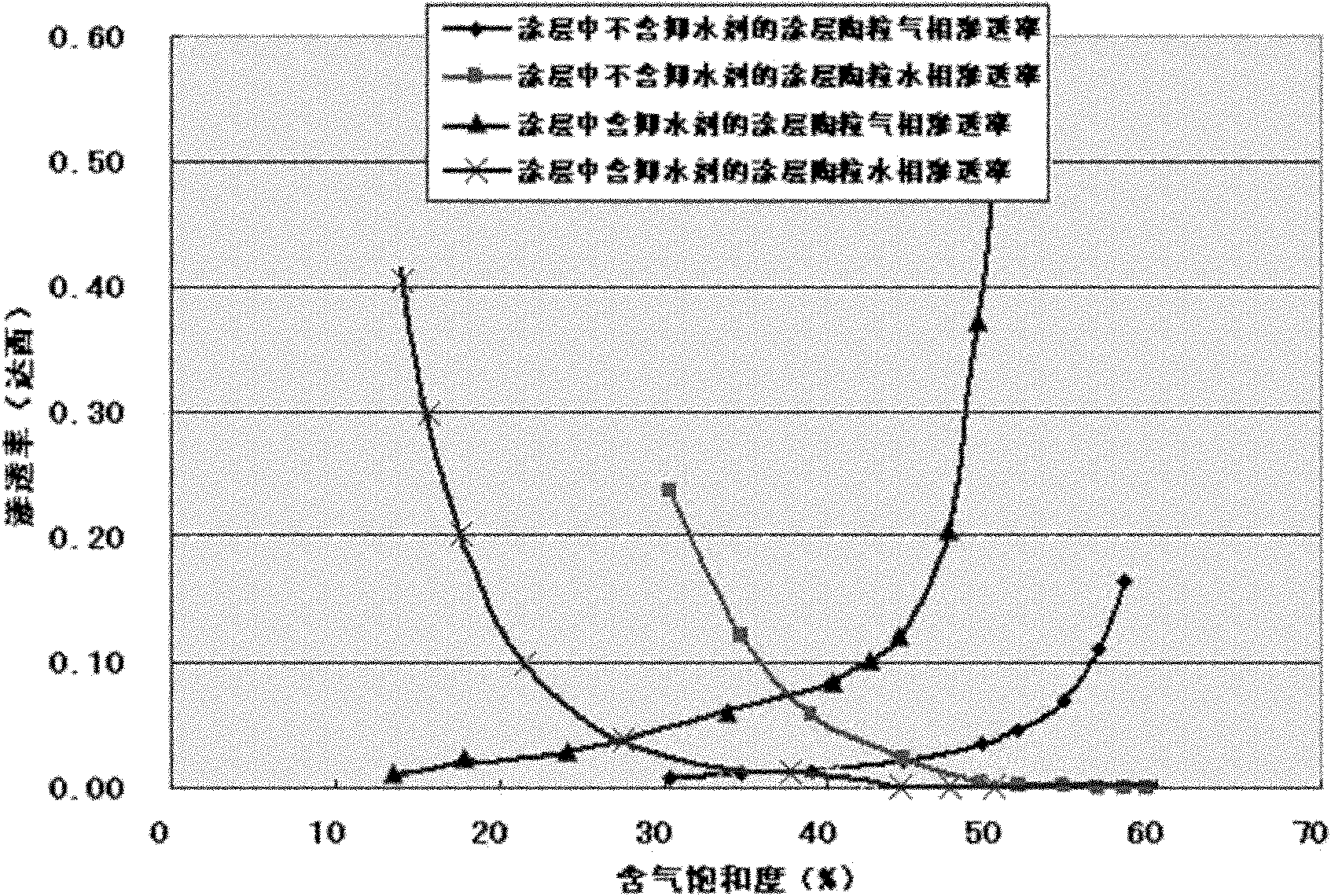

[0036] The gas phase permeability and water phase permeability of the resin-coated quartz sand and resin-coated ceramsite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com