Vertical axis high-power wind driven generator with relatively high wind energy utilization rate

A wind turbine, vertical axis technology, applied to wind turbines, wind turbine components, wind turbines and other directions at right angles to the wind direction, can solve the problems of low wind energy utilization rate, large rotation radius, complex generator structure, etc. Achieve the effect of reducing production and operating costs, simple overall structure, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

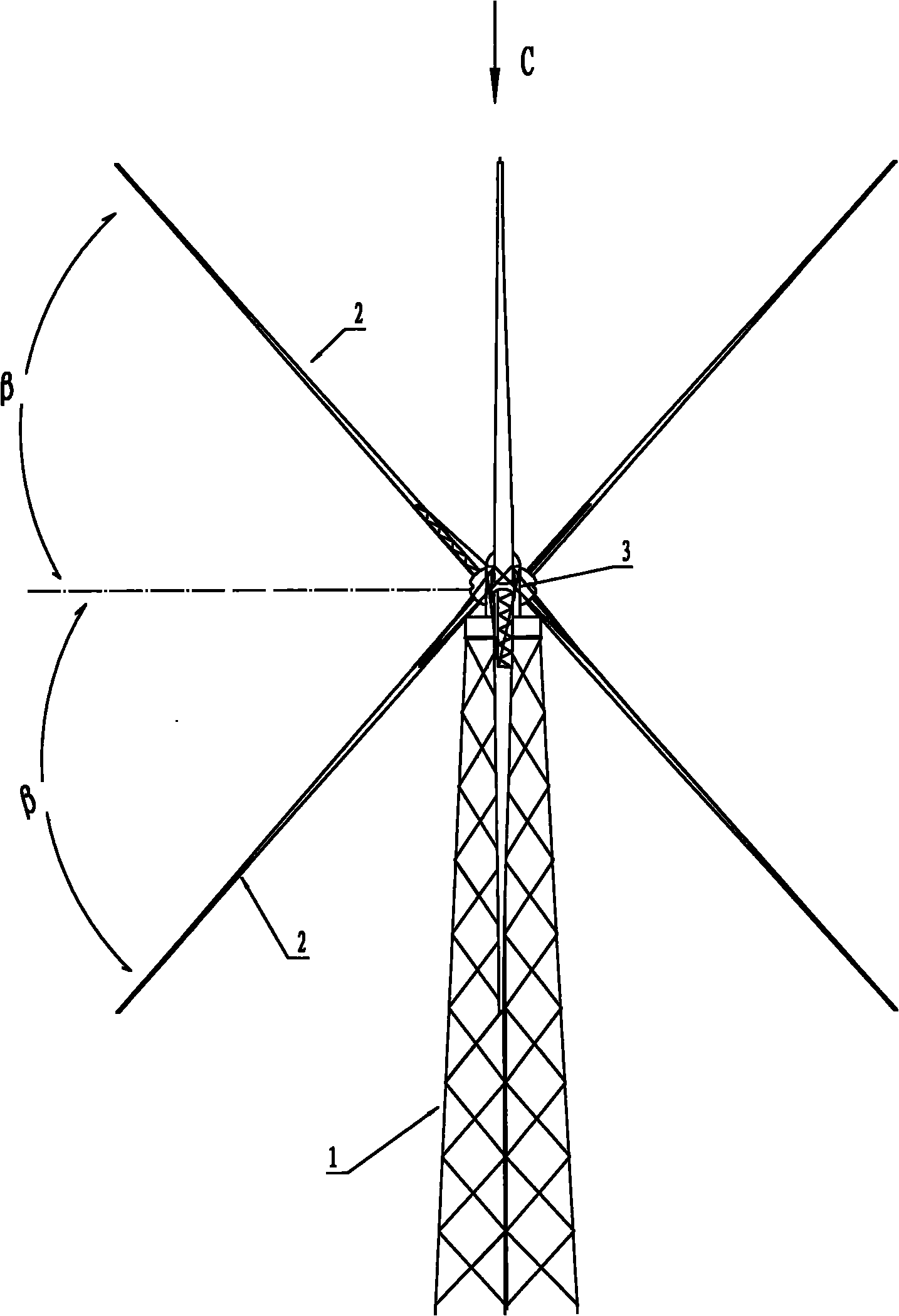

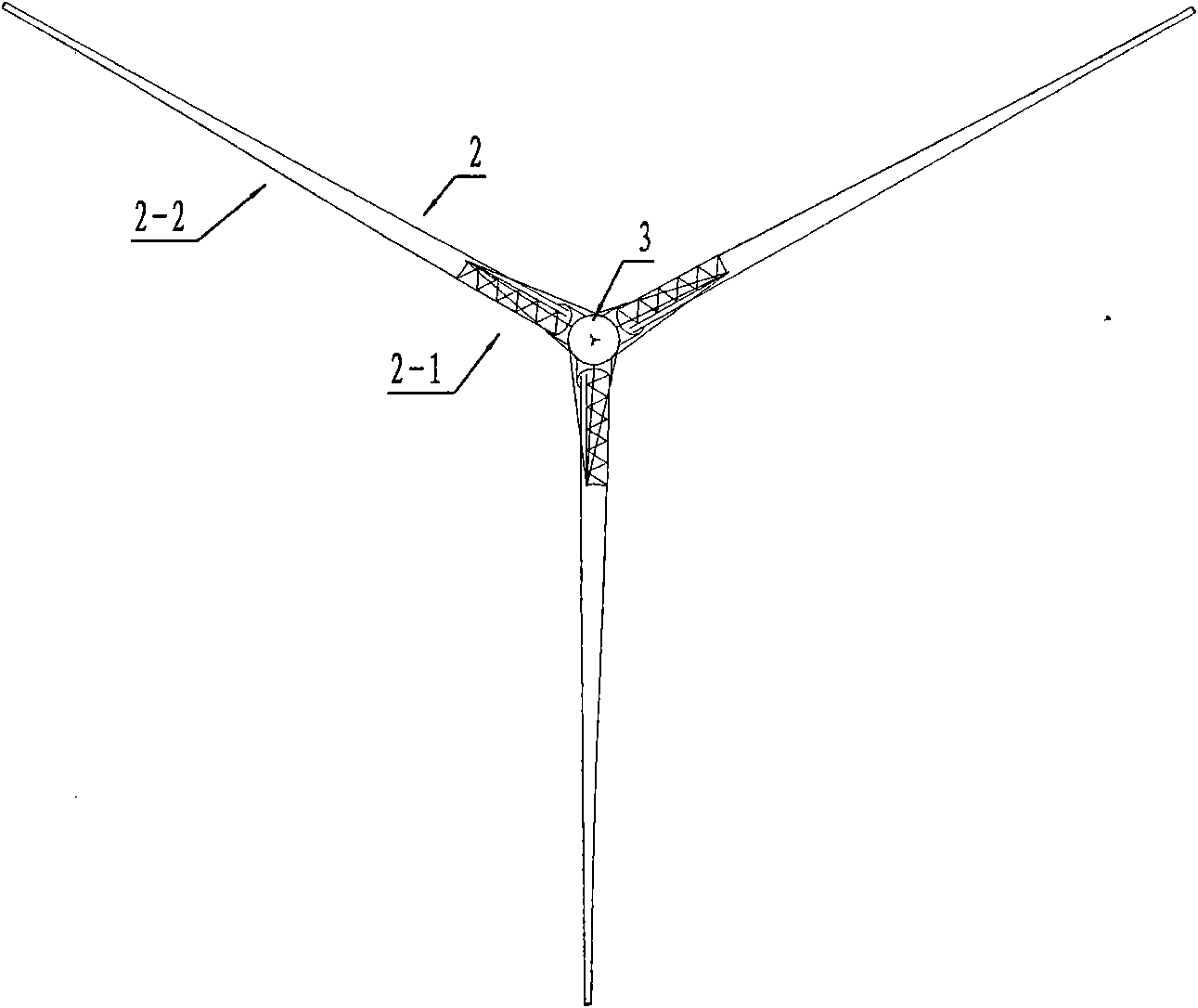

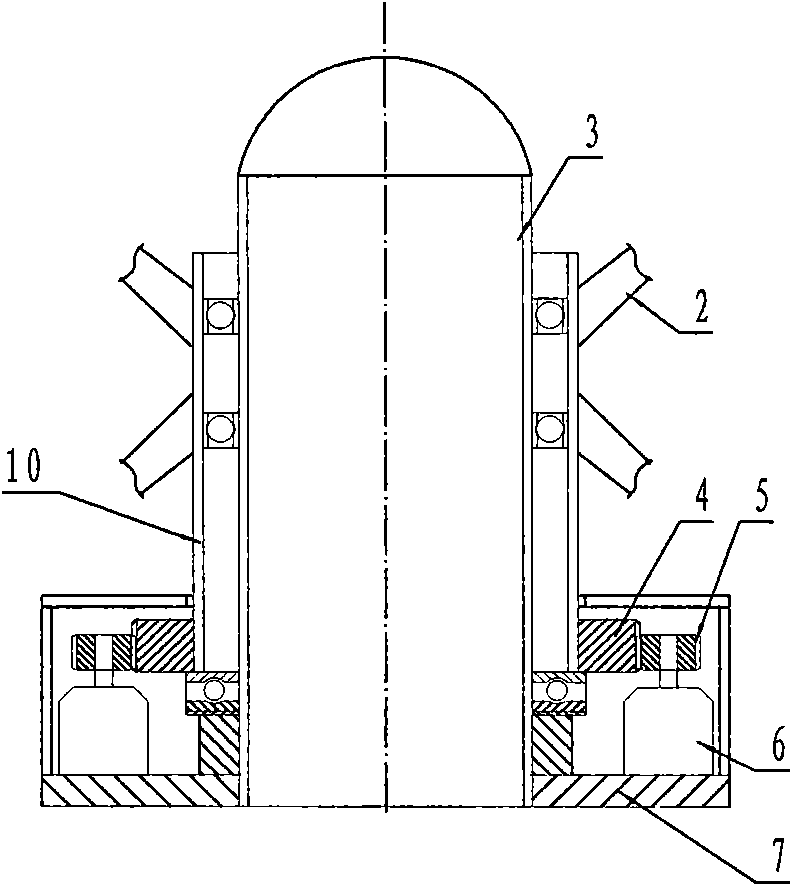

[0019] see figure 1 , figure 2 , the present invention is a vertical axis high-power wind power generator with a brand-new structure, which includes a tower 1, blades 2, a rotating mechanism, a generator, and a center column 3 fixed on the top of the tower. The axes are evenly distributed, and the blades form an acute angle β with the horizontal direction. The number of rows of blades and the degree of β angle can be selected according to factors such as fan power and material strength. The embodiment shown in the figure shows two rows of blades up and down, with three blades in each row, and the angle β between each blade and the horizontal direction is 45°.

[0020] see figure 1 and Figure 4-6 , the present invention improves and optimizes the sectional shape and installation angle of the blade 2 on the basis of the NACA0018 airfoil. The blade adopts a skin-covered truss structure, and the blade sectional shape refers to the cross-sectional shape of the skin. According...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap