Tube type heat exchanger and application of tube type heat exchanger in direct alcohol fuel cell system

A tubular heat exchanger and heat exchanger technology, which can be applied to fuel cell parts, fuel cells, heat exchanger types, etc. The problem of low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

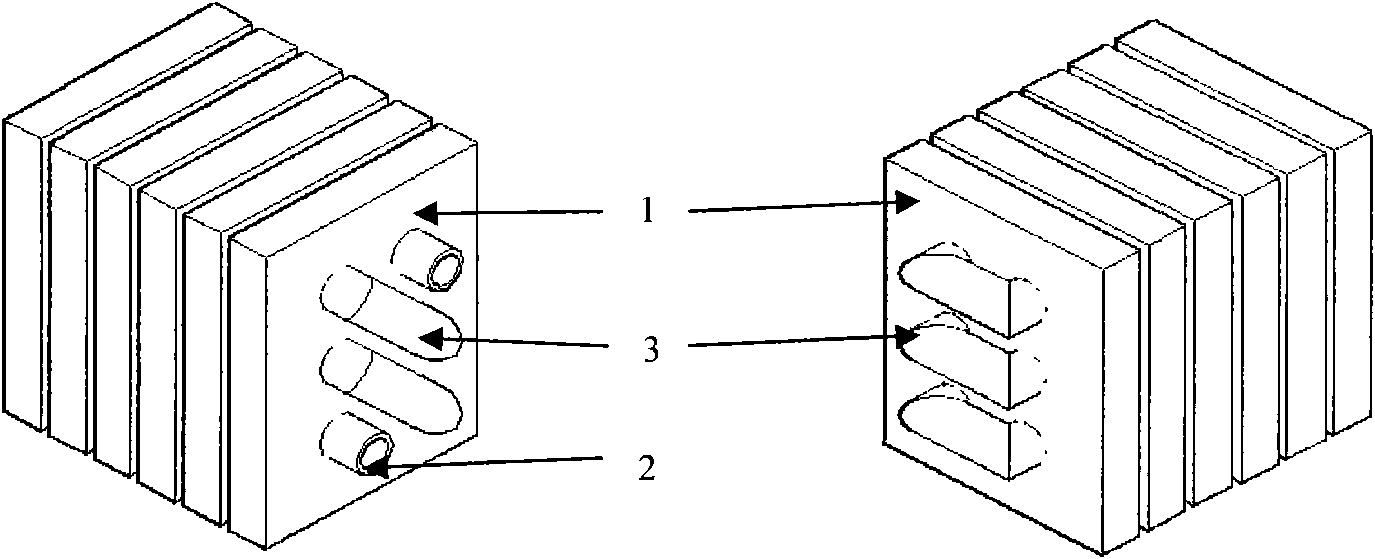

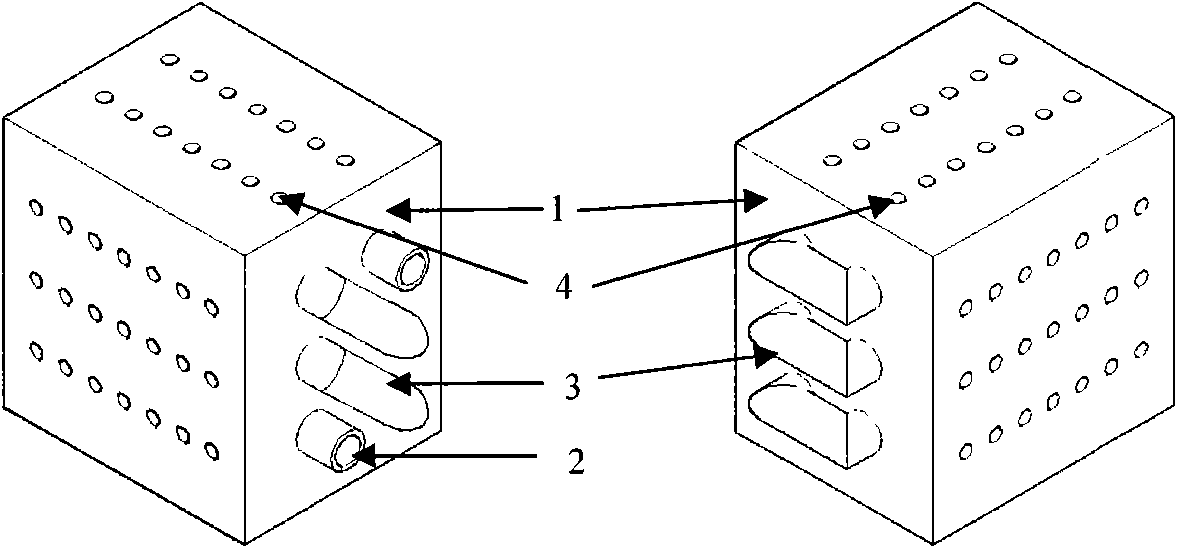

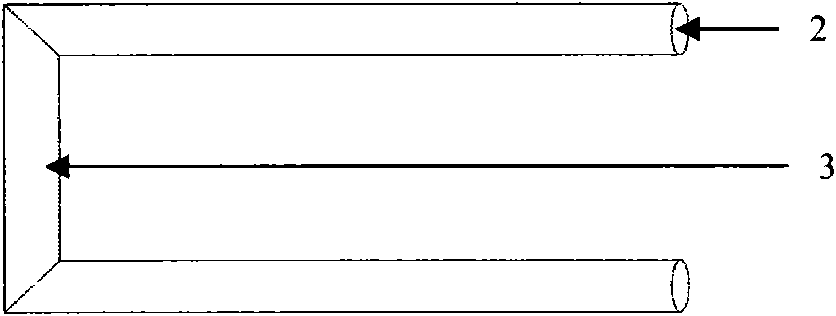

[0027] Traditional tubular heat exchangers are generally composed of heat exchange tubes, enhanced heat exchange elements and auxiliary heat exchange devices. The enhanced heat exchange elements include aluminum foil and fins outside the heat exchange tubes, threaded structures inside the heat exchange tubes, and spoiler cores. Sub, etc., the role is to enhance heat transfer.

[0028] The heat exchanger of the present invention is mainly used in a fuel cell system to achieve the purpose of improving the water-heat balance of the system. This is achieved by removing excess heat from the system, condensing water vapor in the cathode effluent into liquid water and recycling it. Under normal circumstances, the amount of water in the cathode discharge is not very large. If the heat exchange in the heat exchange tube is enhanced, the flow of liquid water may not be smooth. Therefore, increasing the heat exchange area outside the heat exchange tube is one of the ways to solve the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com