Fast drying, stable and anti-vibration weighing device as well as weighing method and use thereof

A technology for fast drying and weighing devices, applied to measuring devices, weighing by removing certain components, weighing materials, etc., can solve the problems of long time consumption, deviation of damaged textiles, long time, etc., and achieve structural Delicate, accurate test, measure fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

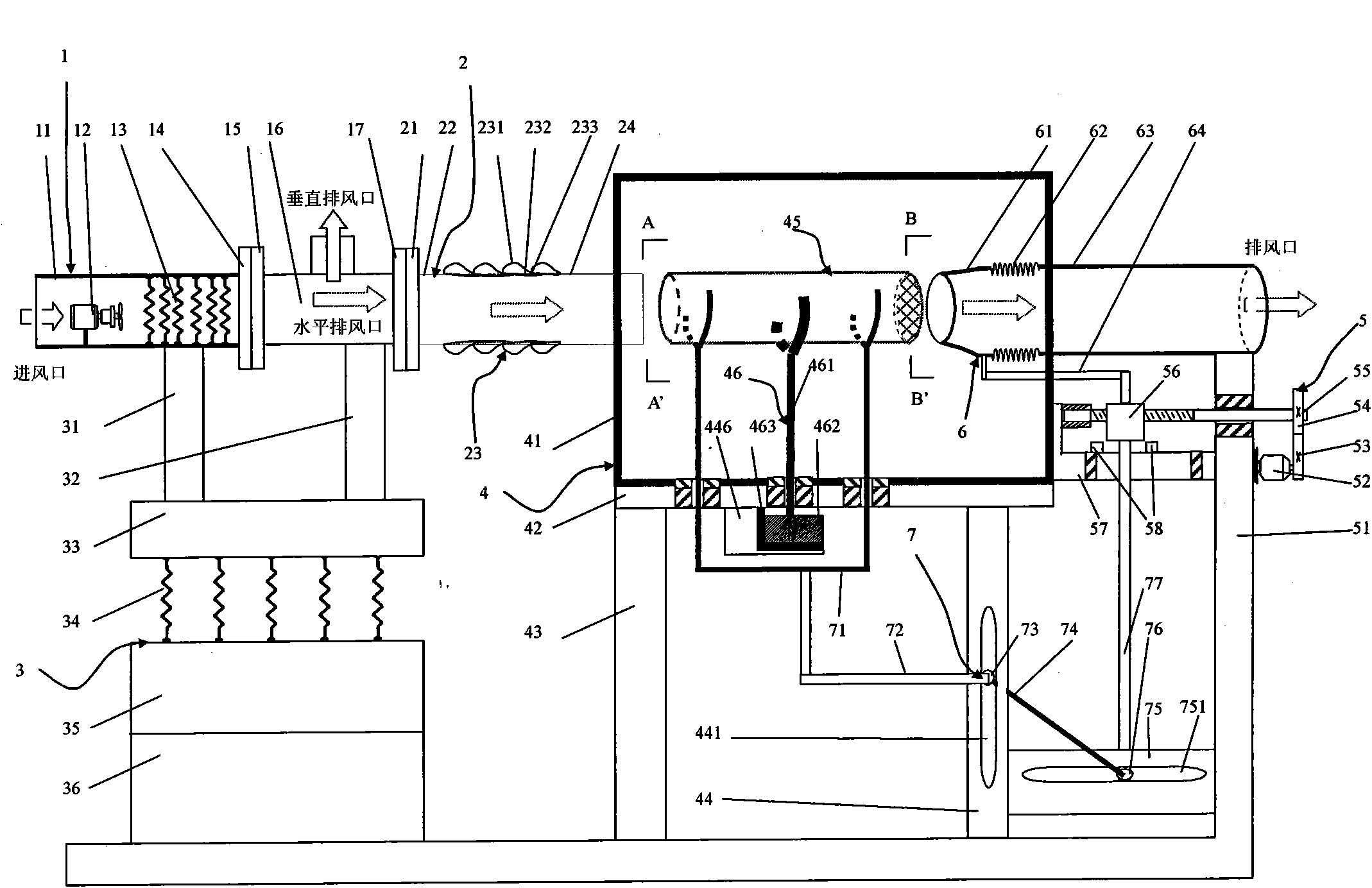

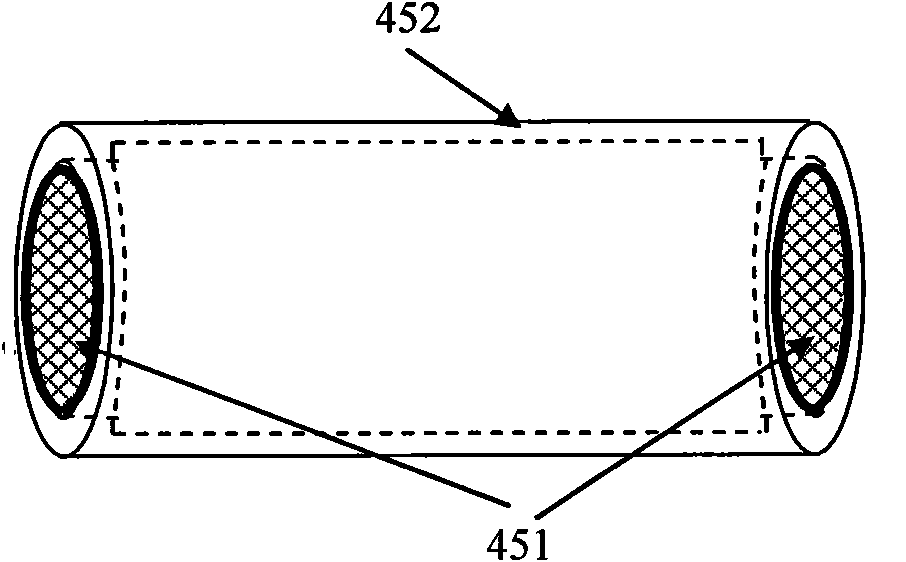

[0051] Embodiment 1 Cotton fiber water content measurement

[0052] Proceed as follows:

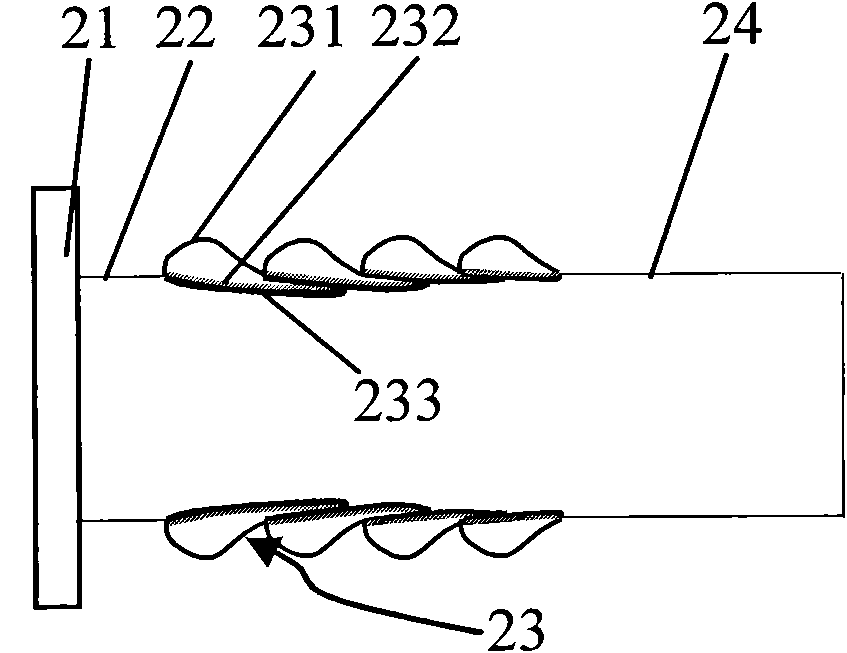

[0053] (1) First weigh the quality G0 of the sample tube 45 that is not filled with cotton fibers to be 11g; connect and couple the sample cover 451 with the sample cup 452 side, take the cotton fiber and put it in the sample cup 452, and then put the The sample cover 451 is connected and coupled with the other side of the sample cup 452; (2) the starter motor 52 drives the worm 53 and the gear 54 to rotate and drives the screw 55 to rotate, and the slider 56 moves horizontally to the right to the stopper 58, and the slider 56 moves Drive the fixed clamping rod 64 and the vertical rod 77 to move horizontally to the right, and the vertical rod 77 moves to the right to drive the second rigid rod 76 to move to the right along the track-shaped hole 751 on the horizontal block 75, and drives the hinged push rod 75 to move to the right. Rod 74 moves to the left, and push rod 74 drives the firs...

Embodiment 2

[0056] Embodiment 2 viscose moisture regain measurement

[0057] Proceed as follows:

[0058](1) First weigh the quality G0 of the sample tube 45 without viscose to be 11g; connect and couple the sample cover 451 with the sample cup 452 side, take the viscose and put it in the sample cup 452, and then place the The sample cover 451 is connected and coupled with the other side of the sample cup 452; (2) the starter motor 52 drives the worm 53 and the gear 54 to rotate and drives the screw 55 to rotate, and the slider 56 moves horizontally to the right to the stopper 58, and the slider 56 moves Drive the fixed clamping rod 64 and the vertical rod 77 to move horizontally to the right, and the vertical rod 77 moves to the right to drive the second rigid rod 76 to move to the right along the track-shaped hole 751 on the horizontal block 75, and drives the hinged push rod 75 to move to the right. Rod 74 moves to the left, and push rod 74 drives the first rigid rod 73 that is hinged...

Embodiment 3

[0060] Embodiment 3 Wool moisture regain measurement

[0061] According to the test method of embodiment 1, the quality G of the sample container 45 that is not loaded with samples is first weighed to be 11.000g; 150 cubic meters per hour; start the temperature range of the induction cooker 13 heating gas to be 105°C; set the reversing time range of the three-way electromagnetic ball valve 16 to be 6 seconds; until the weighing quality constant weight of the sample cylinder 45 is G3 is 15.60g ; The water content C can be obtained through the formula: C=(G1-(1+a)×G3) / ((1+a)×G3-G0), where a is the correction coefficient, the value is -0.01, and the wool content The amount of water C is 12.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com