Grain bearing part structure of lead frame for semiconductor capsulation

A lead frame and carrier technology, applied in the lead frame field, can solve the problems of increased junction resistance, influence on welding quality, open circuit, etc., and achieve the effect of improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in more detail below in conjunction with the drawings and component symbols, so that those skilled in the art can implement them after studying this specification.

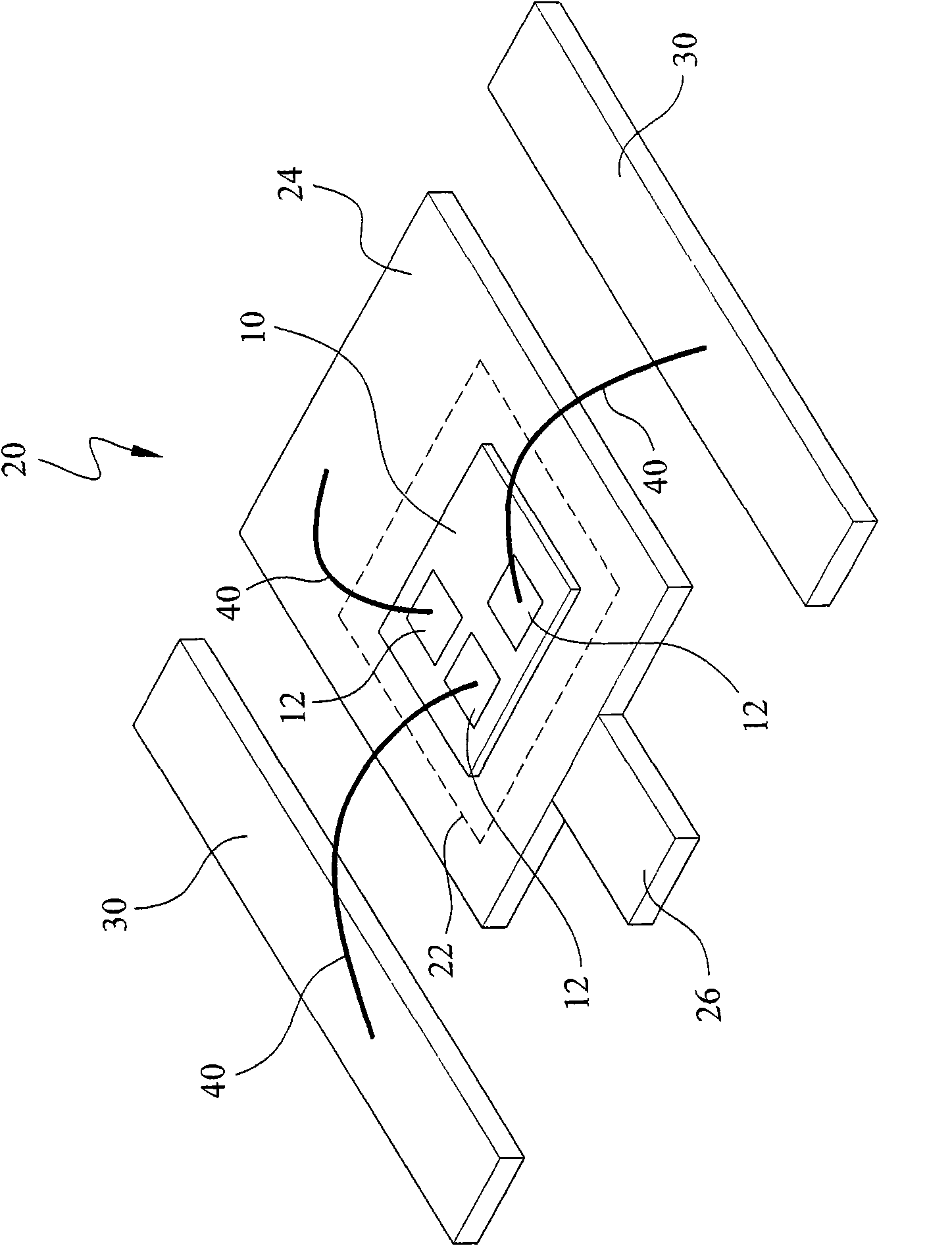

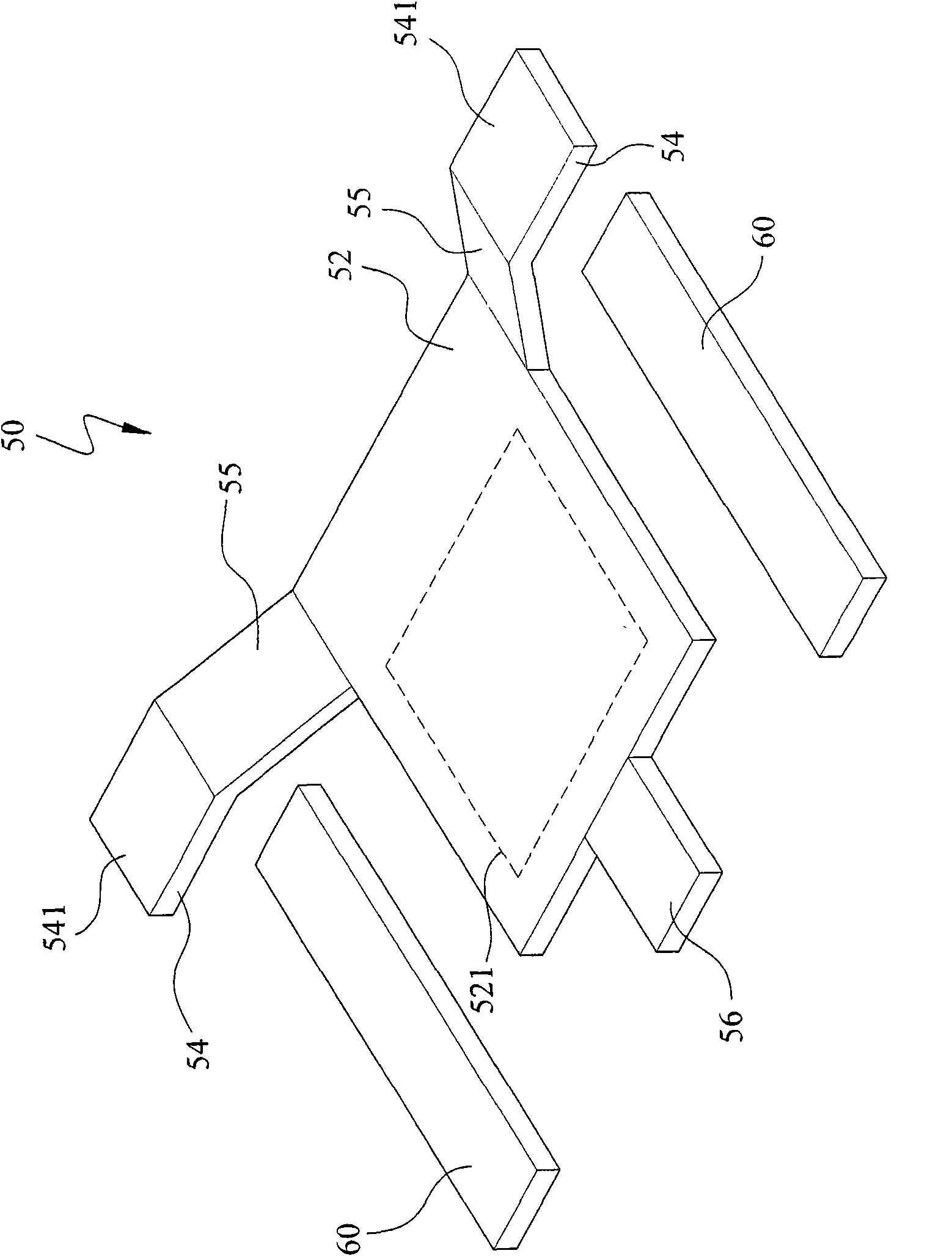

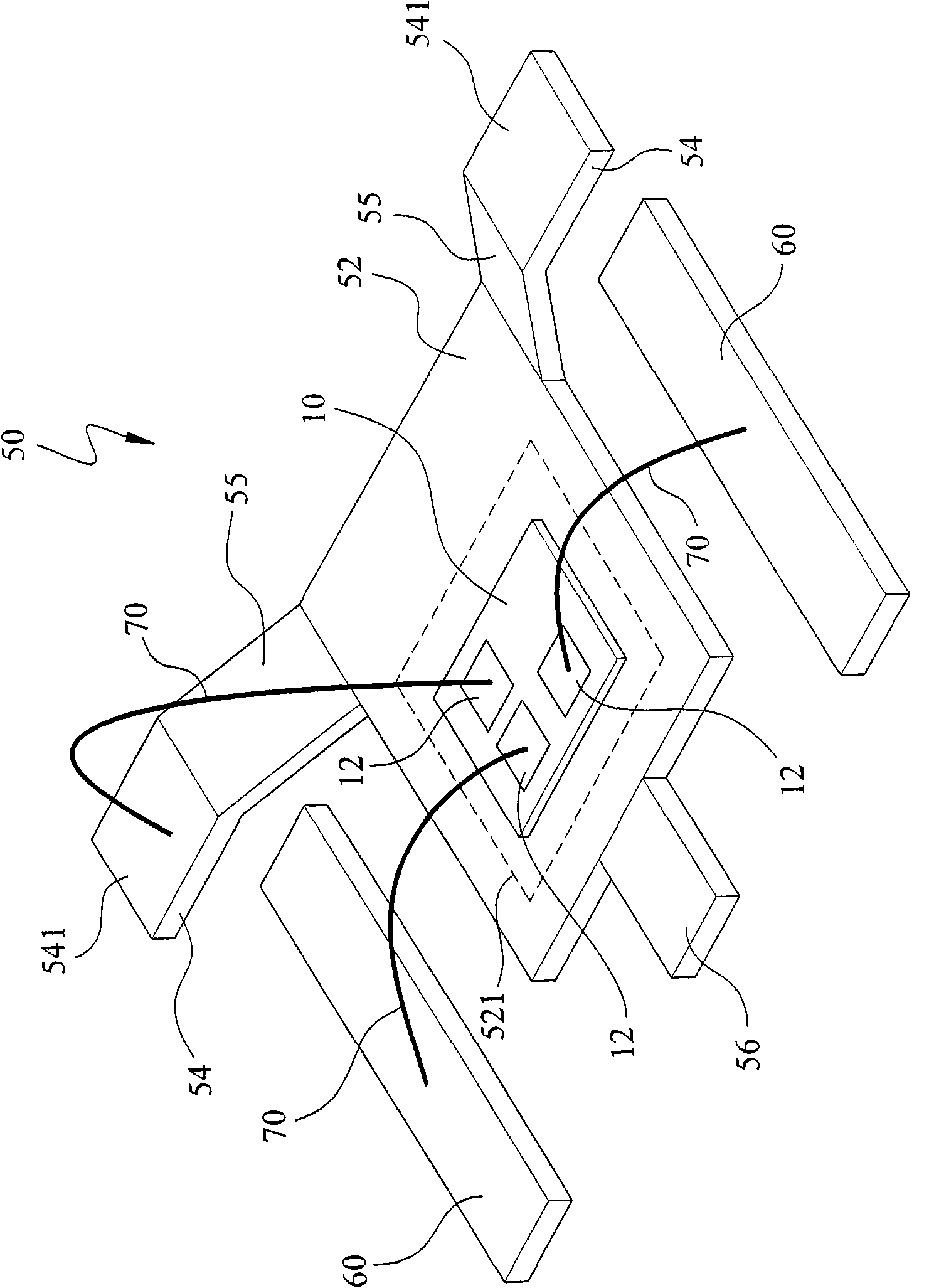

[0036] refer to figure 2 , a schematic diagram of the lead frame of the present invention. The lead frame includes a die carrier 50 and a plurality of leads 60 . Wherein the die carrier 50 is not connected to the leads 60 , the die carrier 50 has a die region 52 , at least one bonding wire region 54 , and at least one connection portion 55 . It should be noted that, for the convenience of describing the features of the present invention, the present embodiment uses the two wire bonding regions 54 and the two connecting portions 55 as exemplary examples for illustration, so the number of the bonding wire regions 54 and the connecting portions 55 is essentially Can contain any positive integer. In addition, in this embodiment, there is also a pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com