Production method of laminated veneer lumber

A technology of laminated veneer and production method, which is applied in the joining of wooden veneers, wood processing appliances, manufacturing tools, etc., can solve the problems affecting the quality of laminated veneer, poor material strength at joints, and consumption of mechanical power and other problems, to achieve the effect of flexible production, increased strength, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

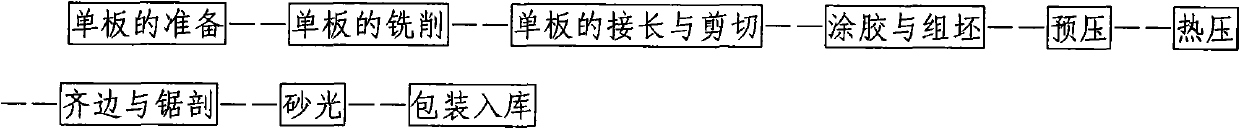

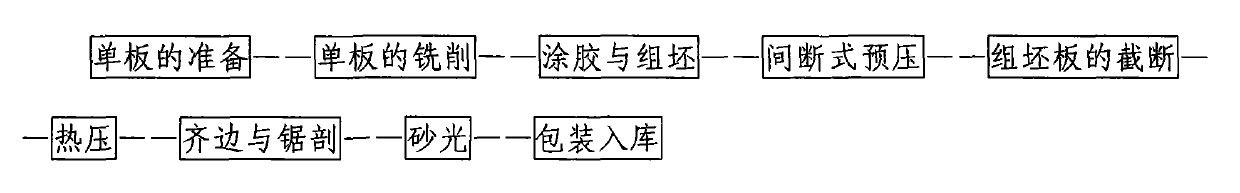

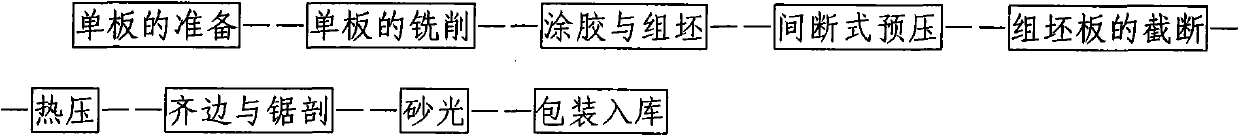

[0045] figure 2 It is a schematic diagram of the production process of an embodiment of the present invention; image 3 It is a schematic diagram of the stacking method of veneer staggered and stacked according to the present invention Figure 1 ; Figure 4 It is a schematic diagram of the stacking method of veneer staggered and stacked according to the present invention Figure 1 .

[0046] Such as Figure 2-Figure 4 Shown: a production method of laminated veneer lumber, comprising the following steps:

[0047] (1) Preparation of the veneer: prepare the veneer 1 with the same length, mill the two ends into inclined planes, and set aside;

[0048] (2) Glue application and blank assembly: apply glue on the surface of each veneer by a glue spreader, and then use the blank assembly machine to assemble the blanks on the blank assembly platform. The blank assembly machine is set on the blank assembly platform A backer, the veneer 1 is placed against the mountain when placed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com