An intelligent reservoir drilling and completion fluid system and its preparation method

A completion fluid and reservoir technology, applied in the field of oil and gas field drilling, can solve the problems of permeability recovery value and initial flow pressure increase, poor reservoir protection effect, etc., achieve good economic and social benefits, and improve reservoir protection effect , strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Take 500mL of water and add it to the mixing cup, turn on the stirrer and stir;

[0040] (2) Add 0.5wt% coating agent BBJ-3 and continue to stir to fully dissolve the coating agent;

[0041] (3) Add 1.0wt% viscosifier VSF-2, continue to stir, and allow it to fully dissolve;

[0042] (4) Add 1.5wt% anti-temperature fluid loss reducer KWJLS-1, continue to stir to make the dissolution even;

[0043] (5) Add 2.0wt% anti-temperature and anti-slump agent FTJ-3, and continue stirring;

[0044] (6) Add 3.0wt% reservoir protection agent CCBHJ-2 and continue stirring;

[0045] (7) Add 2wt% novel modified calcium carbonate XXBHJ-2, continue to stir

[0046] (8) After the above drilling and completion fluid additives are uniformly dissolved, the final product intelligent reservoir drilling and completion fluid system is obtained.

Embodiment 2

[0048] (1) Take 500mL of water and add it to the mixing cup, turn on the stirrer and stir;

[0049] (2) Add 1.0wt% coating agent BBJ-3 and continue stirring to fully dissolve the coating agent;

[0050] (3) Add 1.5wt% viscosifier VSF-2, continue to stir, and allow it to fully dissolve;

[0051] (4) Add 2.0wt% anti-temperature fluid loss reducer KWJLS-1, and continue to stir to make the dissolution even;

[0052] (5) Add 2.5wt% anti-temperature and anti-slump agent FTJ-3, and continue stirring;

[0053] (6) Add 4.0wt% reservoir protection agent CCBHJ-2 and continue stirring;

[0054] (7) Add 3wt% novel modified calcium carbonate XXBHJ-2, continue to stir

[0055] (8) After the above drilling and completion fluid additives are uniformly dissolved, the final product intelligent reservoir drilling and completion fluid system is obtained.

Embodiment 3

[0057] (1) Take 500mL of water and add it to the mixing cup, turn on the stirrer and stir;

[0058] (2) Add 1.0wt% coating agent BBJ-3 and continue stirring to fully dissolve the coating agent;

[0059] (3) Add 2.0wt% viscosifier VSF-2, continue to stir, and allow it to fully dissolve;

[0060] (4) Add 2.5wt% anti-temperature fluid loss reducer KWJLS-1, continue to stir to make the dissolution even;

[0061] (5) Add 3.0wt% anti-temperature and anti-slump agent FTJ-3, and continue stirring;

[0062] (6) Add 4.0wt% reservoir protection agent CCBHJ-2 and continue stirring;

[0063] (7) Add 4wt% novel modified calcium carbonate XXBHJ-2, continue to stir

[0064] (8) After the above drilling and completion fluid additives are uniformly dissolved, the final product intelligent reservoir drilling and completion fluid system is obtained.

[0065] The basis of the mass percent of each component in Examples 1-3 is water.

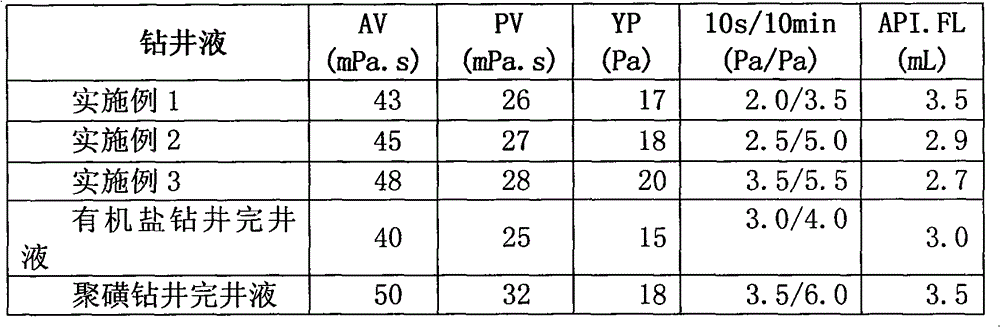

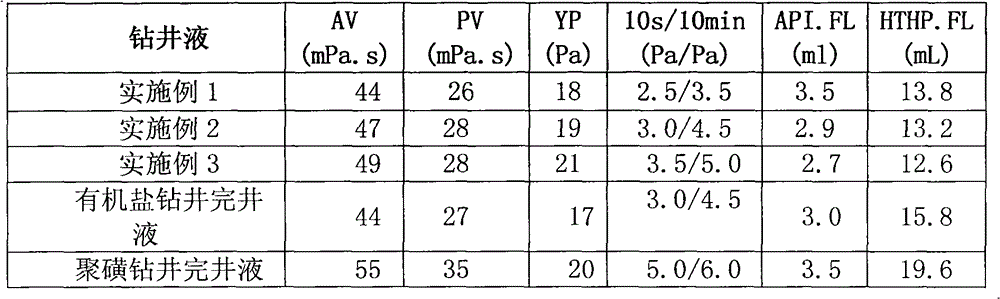

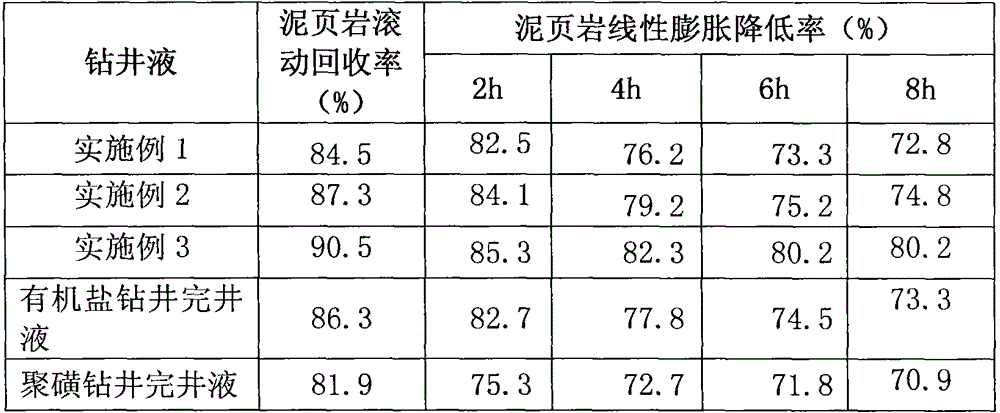

[0066] Embodiment performance evaluation method

[0067] 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com