Oil extraction method of weight adding under pump and oil well pump with weight adding under pump

An oil pump and under-pump technology, which is applied in the direction of pump, production of fluid, and earth-moving drilling, etc., can solve the problems of leakage, wear and tear of the oil pipe on the pump, and poor performance, so as to prolong the service life, reduce mutual wear, and reduce eccentric wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

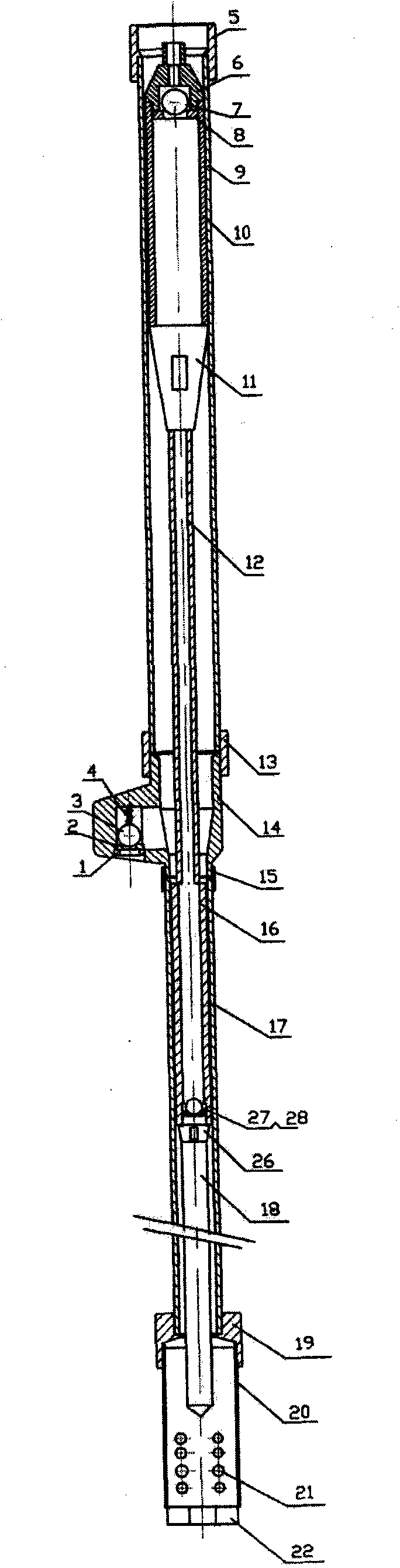

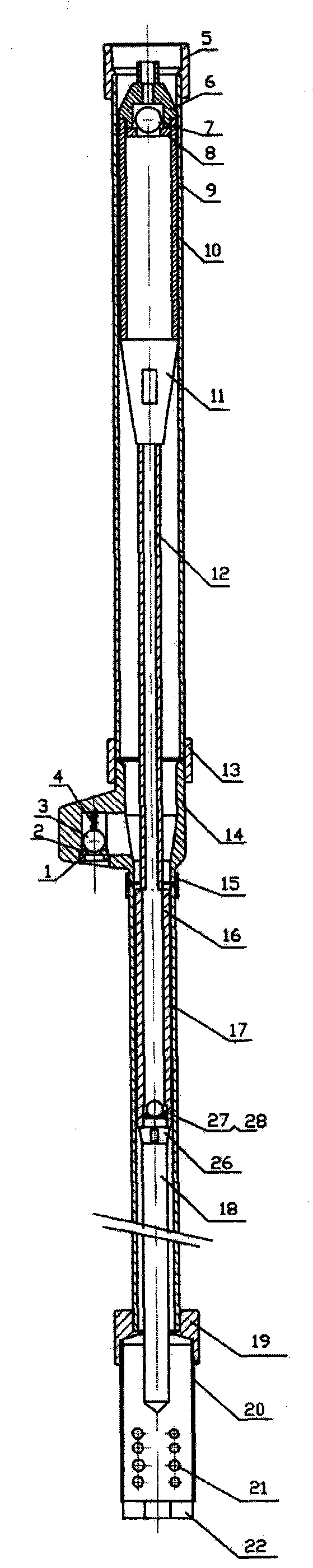

[0019] An under-pump weighted oil well pump used for an under-pump weighted oil production method includes a pump barrel assembly, a plunger assembly and an auxiliary mechanism under the pump. The plunger assembly is provided with a liquid outlet valve and a liquid inlet valve. The upper plunger 10 and The lower plunger 16 is connected with the connecting rod 12 through the lower plunger joint 11, and the weighting rod 18 is connected under the plunger assembly. The weighted rod 18 is connected with the lower plunger 16 of the plunger assembly through a weighted rod joint 26 . Connect the auxiliary mechanism under the pump under the pump barrel assembly. The auxiliary mechanism under the pump includes the tail pipe joint 19, the tail pipe 20, the screen pipe 21 and the plug 22 connected in sequence. The connection between the tail pipe joint 19 and the pump barrel assembly The lower pump barrel 17 is connected. The liquid inlet valve includes a pump external offset liquid inl...

Embodiment 2

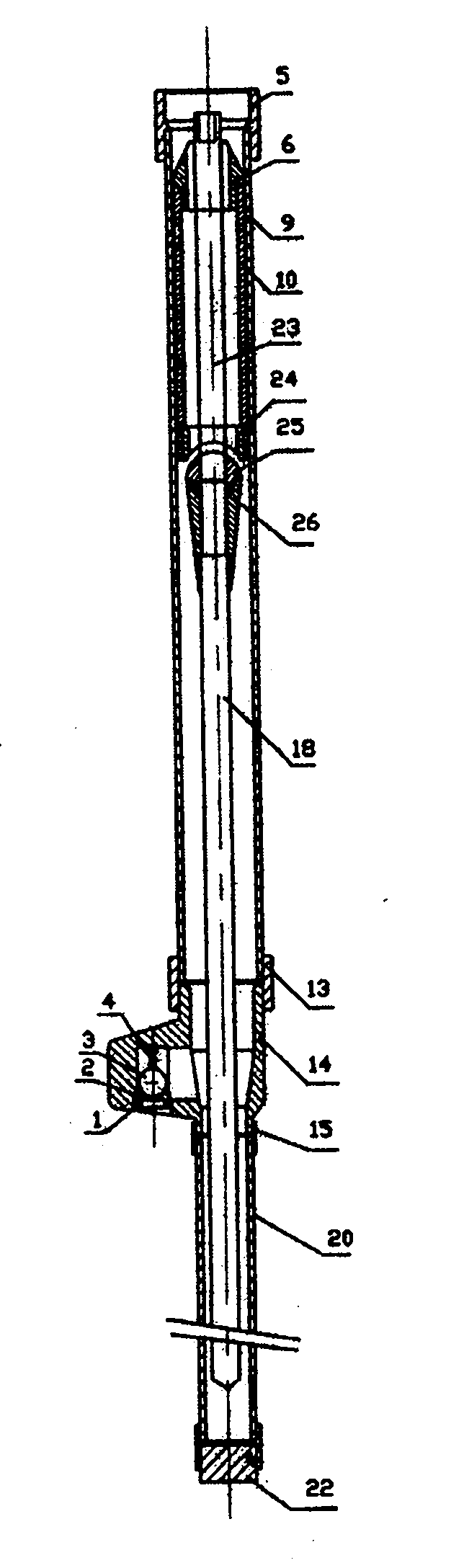

[0023] The under-pump weighted oil well pump used for an under-pump weighted oil production method includes a pump barrel assembly, a plunger assembly and an auxiliary mechanism under the pump. The plunger assembly is provided with a liquid outlet valve and a liquid inlet valve, and the weight rod 18 is connected to Under the plunger assembly, connect the pump down auxiliary mechanism under the pump barrel assembly. The weighted rod 18 is connected with the connecting rod 23 of the plunger assembly through a weighted rod joint 26 . The auxiliary mechanism under the pump includes a tailpipe 20 and a plug 22 to connect the tailpipe 20 with the lower joint 15 of the pump. The liquid outlet valve includes an upper joint 6 on the plunger, an upper sealing seat 24 on the plunger and a lower sealing seat 25 on the plunger. The upper sealing seat 24 of the plunger is connected sequentially; the lower sealing seat 25 of the plunger is fixed on the lower part of the connecting rod 23, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com