Integrated type LED floodlight lamp

An LED light source and integrated technology, which is applied in the field of integral LED floodlights, can solve the problems of lamp power consumption, stability, service life performance, cost control, inconvenient installation of lamps, and insufficient brightness of single-chip LEDs. Achieve the effect of improving stability and service life, convenient processing and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

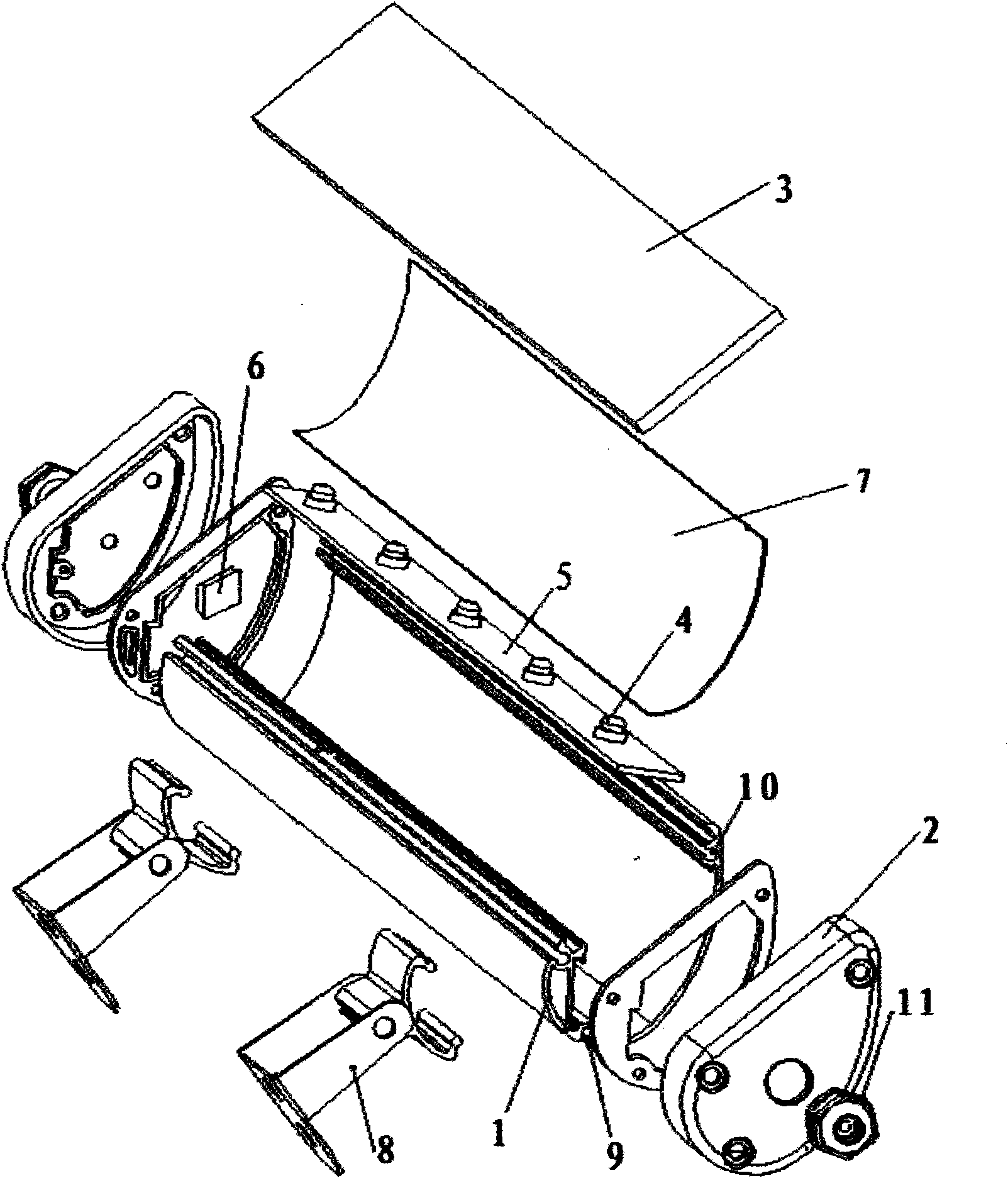

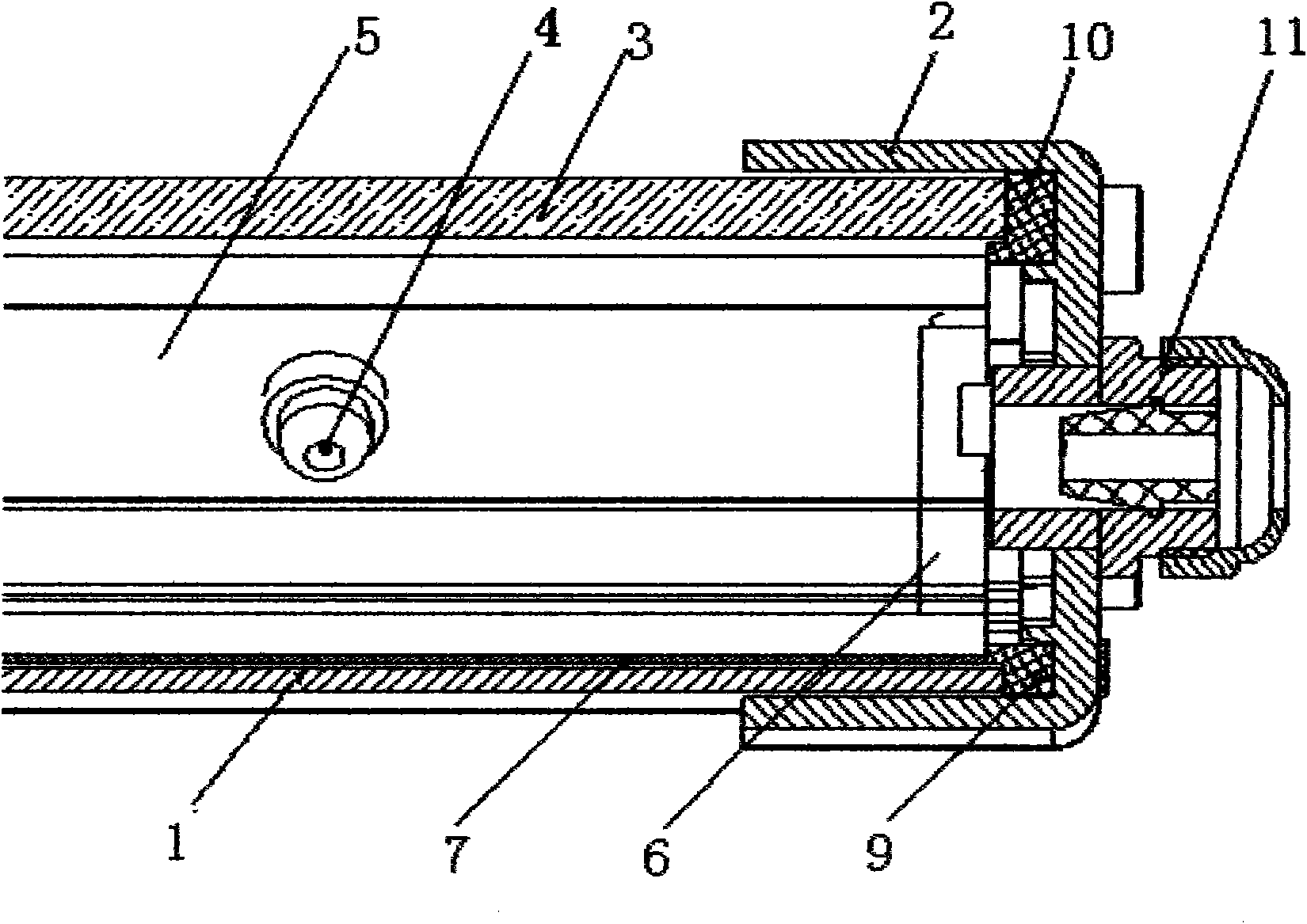

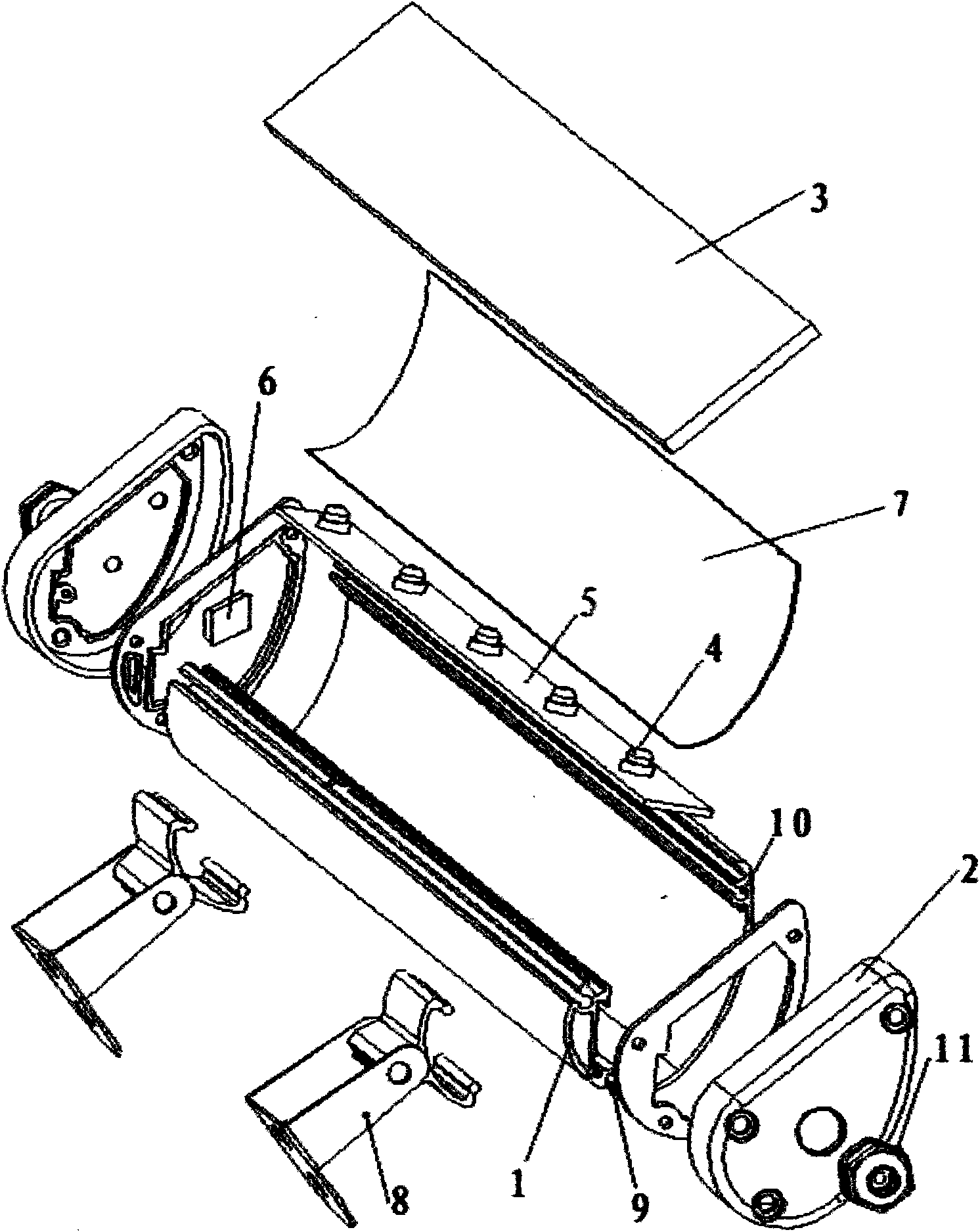

[0031] An integral LED floodlight, the LED light source 4 is packaged on an aluminum alloy heat-conducting substrate 5, the lamp body shell 1 and the light-transmitting panel 3 form a closed space, in which two heat-conducting heat-conducting panels encapsulating the LED light source 4 are arranged. The substrate 5, the lamp body shell 1, the heat-conducting substrate 5, and the LED light source 4 are filled and contacted by heat-conducting glue. The heat conduction path of "LED light source 4→heat conduction substrate 5→lamp housing 1→outside" effectively dissipates the heat generated by the LED light source 4 .

[0032] The power line is connected to the closed space where the LED power supply and the drive control circuit 6 are placed through the waterproof connector 11 on the end cover 2. The reserved wire slot is connected to the enclosed space where the LED light source 4 is placed. The LED light source 4 packaged on the single heat-conducting substrate 5 is connected in...

Embodiment 2

[0038]LED strip wall washer includes red, green and blue monochromatic LED light sources, each aluminum alloy heat-conducting substrate 5 packages red, green and blue three monochromatic LED light sources, the lamp body shell 1 and the light-transmitting panel 3 are solidly formed A closed space, in which a heat-conducting substrate 5 is placed, the lamp body shell 1, heat-conducting substrate 5, and LED light source 4 are connected and contacted by a heat-conducting silicone cushion, the lamp body shell 1 and its heat dissipation structure, and the placement and implementation of electrical components 1 is the same.

[0039] In this embodiment, the connection of the lighting circuit is basically the same as that in Embodiment 1, the difference is that among the LED light sources 4 packaged on each heat-conducting substrate 5 , the light sources of the same color are connected in series, and the light sources of different colors are connected in parallel.

[0040] In this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com