Anode material capable of being used for lithium-iodine cell and preparation method thereof

A positive electrode material and battery technology, applied in the field of electrochemistry, can solve the problems of high internal resistance, high raw material cost, and high heating temperature of lithium-iodine batteries, and achieve the effects of low cost, simple preparation method, and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Preparation of a series of iodine-containing cathode materials LiI(HPN) by a simple heating method 2 -xI 2 (10≥x≥0.1). The color of the material changes with the iodine content. The color changes from dark yellow when the iodine content is low to bright gold when x=0.6. Continue to increase the iodine content to x≥2, and the material color turns gray-black with a certain Metallic luster.

[0013] According to different x values (10≥x≥0.1) during preparation, weigh the corresponding weight ratio of LiI(HPN) 2 and elemental I 2 , heated in an oil bath at different temperatures (90 to 135 degrees Celsius) for 0.5 to 1 hour. For example, to prepare a positive electrode material with x=0.1: weigh LiI(HPN) with a weight ratio of 10.9:1 2 with I 2 After mixing and grinding evenly, heat and stir in an oil bath at 135 degrees Celsius for 1 hour, and obtain LiI(HPN) after cooling 2 -0.1I 2 Sample; preparation of positive electrode material with x=3: weigh LiI(HPN) with...

Embodiment 2

[0015] Weigh iodine content x=1 (i.e. LiI(HPN) 2 -I 2 ) of material 0.08g, pressed to an area of 1cm under a pressure of 500kpa 2 The positive electrode disk, and then the positive electrode disk is directly contacted with the lithium sheet to form a lithium-iodine battery.

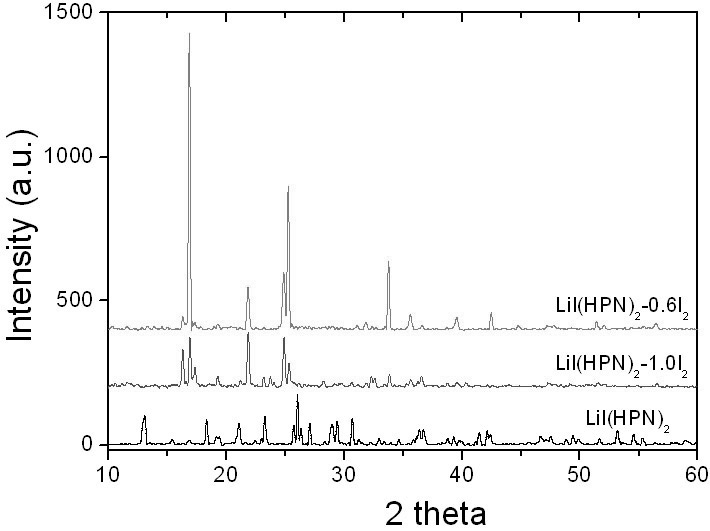

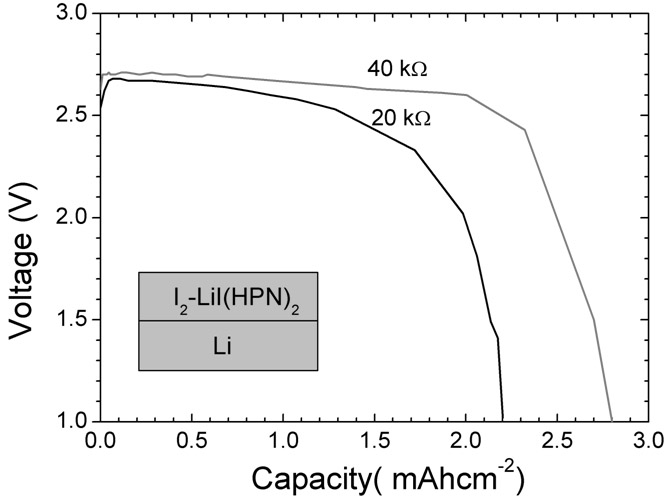

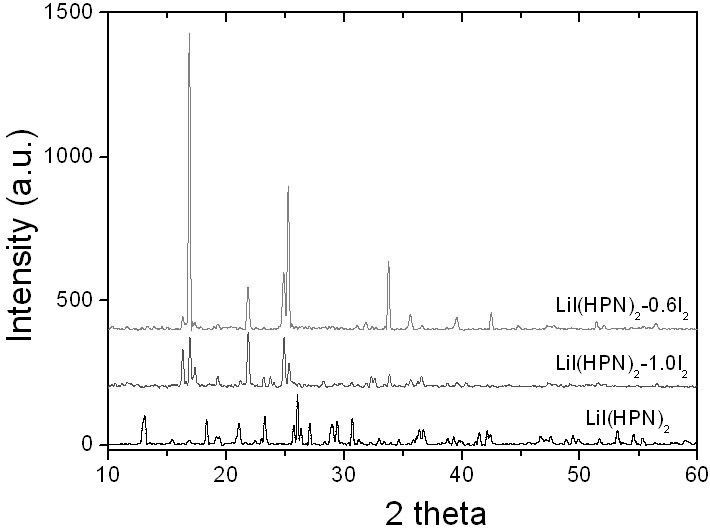

[0016] X-ray diffraction measurements show that LiI(HPN) 2 -0.6I 2 The positive electrode material is a kind of different from LiI(HPN) 2 The new structure of the new substance with a good crystal state (attached figure 1 ). to LiI(HPN) 2 -I 2 The electrochemical performance test results of the lithium-iodine battery composed of positive electrode materials are as follows: the lithium-iodine battery is discharged under the load of 40kΩ and 20kΩ respectively, and has good discharge performance, and the current density is about 65mA / cm 2 and 100 mA / cm 2 (attached figure 2 ). The specific capacity under 40kΩ load is 35mAh / g, that is, the formation of LiI(HPN) 2 -I 2 Cathode materials with sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com