Resistor built-in printing circuit board and manufacturing process thereof

A technology of printed circuit boards and embedded resistors, which is applied in the direction of printed circuits, printed circuit manufacturing, and printed electrical components. It can solve the problems of poor signal conversion effect and large volume of components, and achieve reduced size and reliable signals. , the effect of reducing signal crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

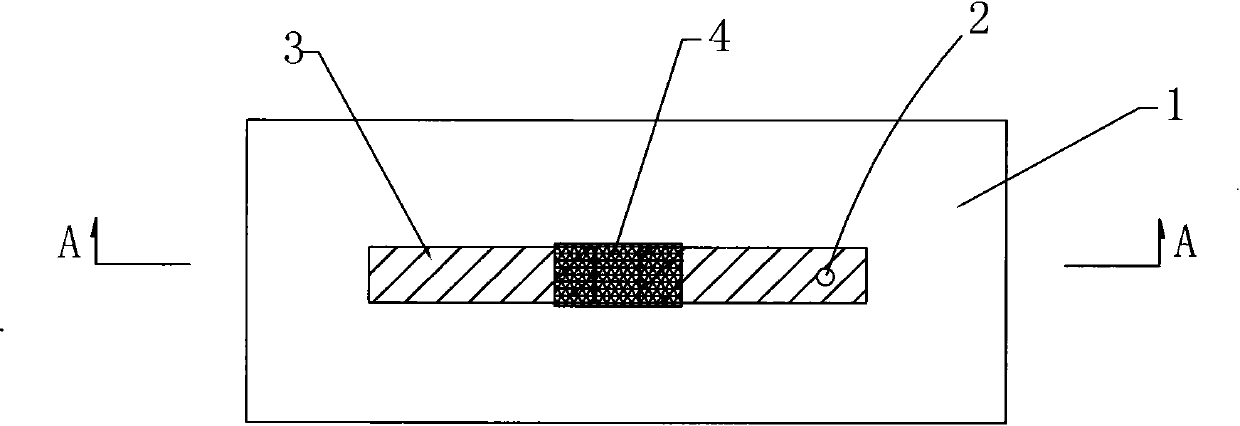

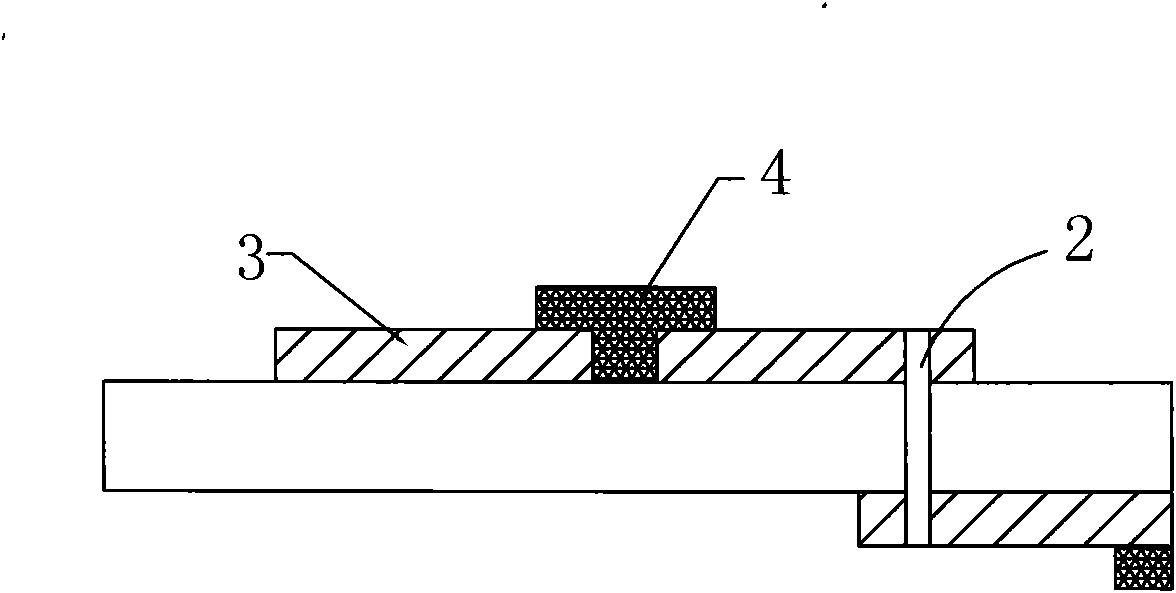

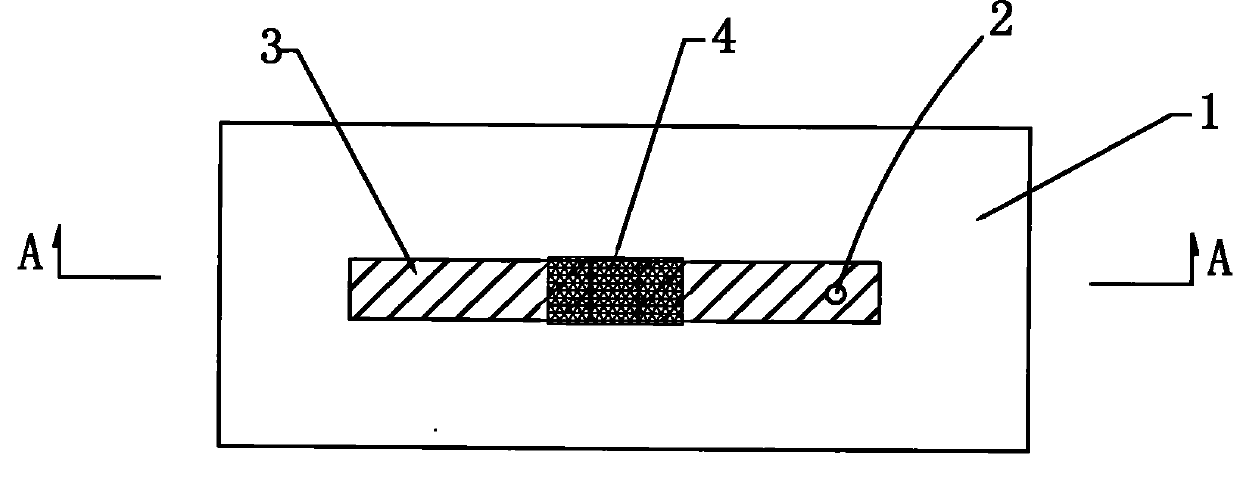

[0019] Embodiment: A printed circuit board with embedded resistors, comprising an insulating substrate 1, a metal circuit layer formed on the surface of the insulating substrate 1, and an interlayer via hole 2 corresponding to the hole wall of the conductive metal circuit layer covering the metal layer, The part where the metal circuit layer is exposed on the surface of the insulating substrate is covered with an insulating ink layer, and at least a pair of electrodes 3 are formed in the metal circuit layer, and the insulating substrate between each pair of electrodes 3 is covered with a resistance layer 4, and each resistance layer 4 extends The electrode 3 covering its two ends is on one end close to the resistance layer.

[0020] The resistance layer 4 is a carbon oil film layer, and its resistance value is 1K-100K ohms.

[0021] A manufacturing process of a printed circuit board with embedded resistors, comprising the following steps in sequence:

[0022] A. Cutting: Cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com